Mazda CX 7. Manual - part 94

SYMPTOM TROUBLESHOOTING [L3 WITH TC]

01-03–73

01-03

End Of Sie

NO.29 SPARK PLUG CONDITION[L3 WITH TC]

id010339803600

Diagnostic procedure

3

Verify test results.

• If normal, return to the diagnostic index to service any additional symptoms.

• If a malfunction remains, inspect the related Service Bulletins and/or On-line Repair Information and perform the

repair or diagnosis.

— If the vehicle is repaired, troubleshooting is completed.

— If the vehicle is not repaired or additional diagnostic information is not available, reprogram the PCM if a later

calibration is available. Retest.

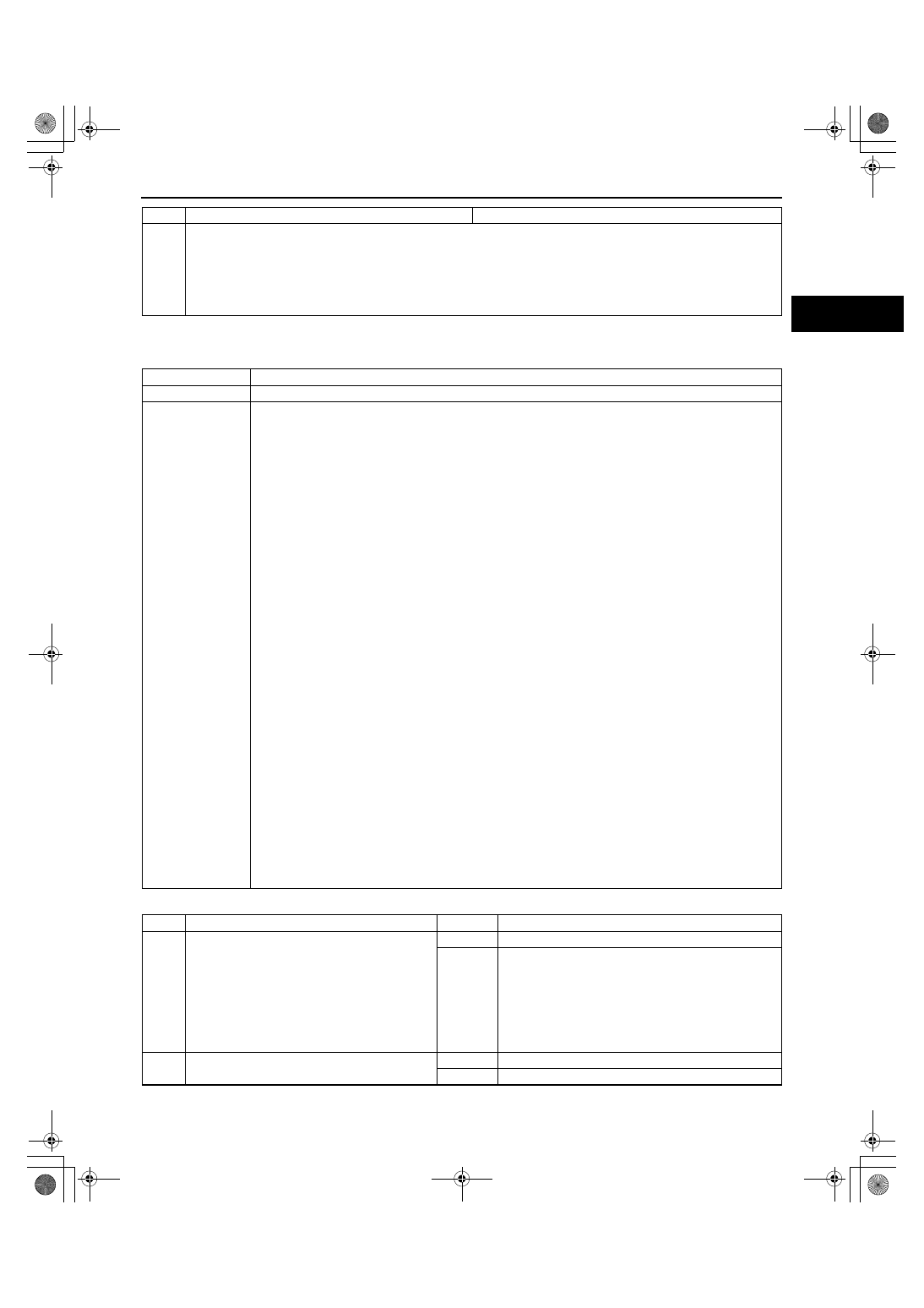

STEP

INSPECTION

ACTION

29

SPARK PLUG CONDITION

DESCRIPTION

Incorrect spark plug condition

POSSIBLE CAUSE

Note

• Inspecting the condition of the spark plugs can determine whether a problem is related to a

specific cylinder or possibly all cylinders.

Wet/carbon stuck on specific plug:

• Spark— Weak, not visible

• Air/fuel mixture— Excessive fuel injection volume

• Compression— No compression, low compression

• Malfunctioning spark plug

Grayish white with specific plug:

• Air/fuel mixture— Insufficient fuel injection volume

• Malfunctioning spark plug

Wet/carbon is stuck on all plugs:

• Spark— Spark weak

• Air/fuel mixture— Too rich

• Compression— Low compression

• Clogging in intake/exhaust system

Grayish white with all plugs:

• Air/fuel mixture— Too lean

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before servicing the fuel system:

• Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always

keep sparks and flames away from fuel.

• Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or

death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete

“BEFORE REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this

manual.

(See01-14-4 BEFORE REPAIR PROCEDURE[L3 WITH TC].)

(See01-14-4 AFTER REPAIR PROCEDURE[L3 WITH TC].)

Caution

• Disconnecting/connecting the quick release connector without cleaning it may possibly

cause damage to the fuel pipe and quick release connector. Always clean the quick release

connector joint area before disconnecting/connecting, and make sure that it is free of

foreign material.

STEP

INSPECTION

RESULTS

ACTION

1

Remove all the spark plugs.

Inspect the spark plug condition.

Is the spark plug condition normal?

Yes

Troubleshooting completed.

No

Specific plug is wet or covered with carbon:

Go to the next step.

Specific plug looks grayish white:

Go to Step 9.

All plugs are wet or covered with carbon:

Go to Step 11.

All plugs look grayish white:

Go to Step 19.

2

Is the spark plug wet/covered with carbon from

engine oil?

Yes

Inspect all areas related to oil.

No

Go to the next step.

1871-1U-06B(01-03).fm 73 ページ 2006年3月15日 水曜日 午前10時36分