Mazda CX 7. Manual - part 56

ON-BOARD DIAGNOSTIC [L3 WITH TC]

01-02–179

01-02

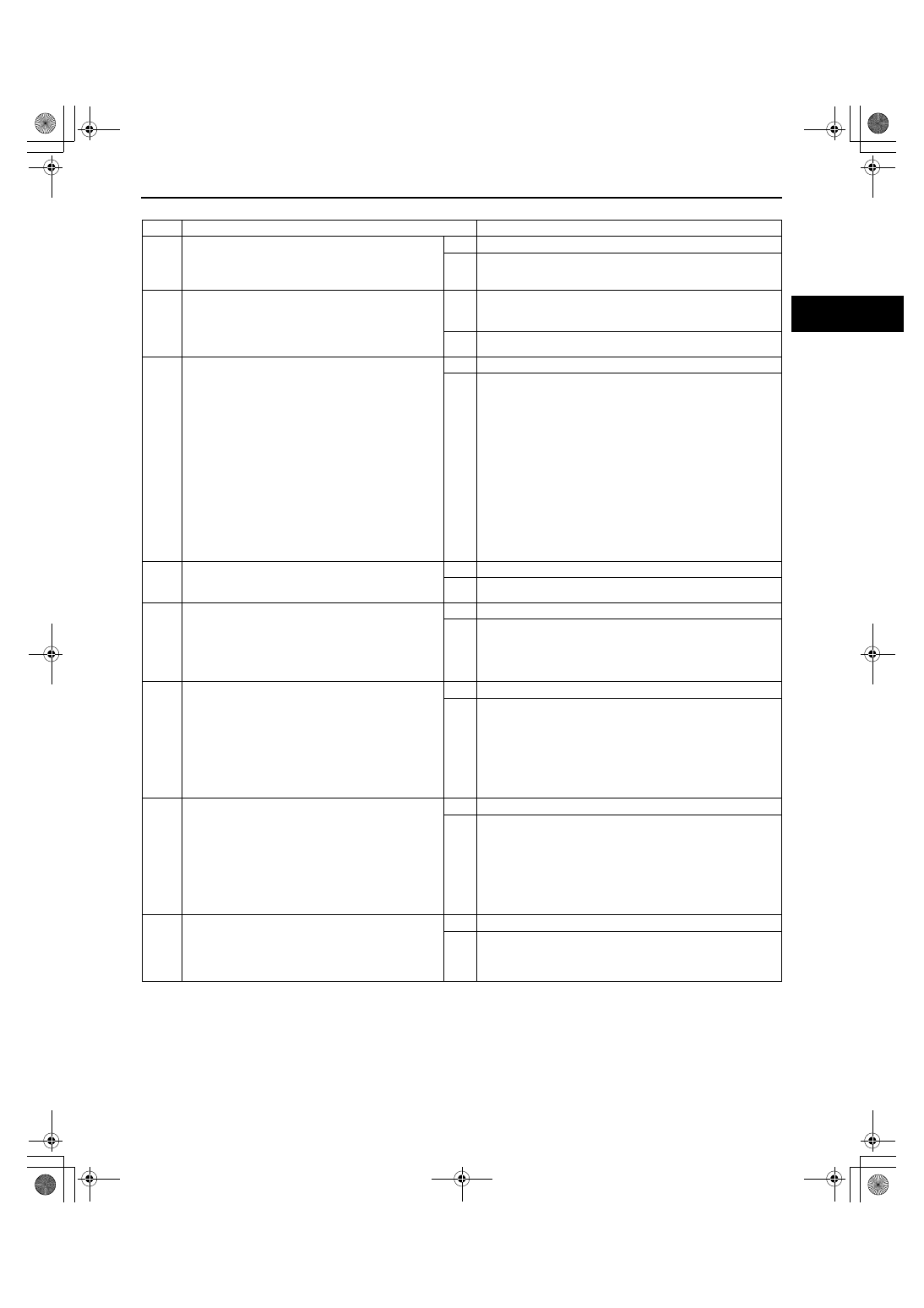

Diagnostic procedure

STEP

INSPECTION

ACTION

1

VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

• Has the FREEZE FRAME DATA been

recorded?

Yes

Go to the next step.

No

Record FREEZE FRAME DATA on the repair order, then go

to the next step.

2

VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

• Check for related Service Bulletins and/or on-

line repair information availability.

• Is any related repair information available?

Yes

Perform the repair or diagnosis according to the available

repair information.

• If the vehicle is not repaired, go to the next step.

No

Go to the next step.

3

CLASSIFY INTERMITTENT CONCERN OR

CONTINUOUS CONCERN

• Clear the DTC from the PCM memory using

the M-MDS.

• Drive the vehicle under the following

conditions:

— Engine coolant temperature is above 63

°C

{145

°F}.

— Engine speed: below 3,750 rpm

— Throttle opening angle is as follows:

• Engine speed below 1,500 rpm: above

35%

• Engine speed between 1,500— 2,500

rpm: between 25— 35%

• Engine speed above 2,500: below 25%

• Is the PENDING CODE for this DTC present?

Yes

Go to the next step.

No

Intermittent concern exists. Go to INTERMITTENT

CONCERN TROUBLESHOOTING procedure.

(See01-03-76 INTERMITTENT CONCERN

TROUBLESHOOTING[L3 WITH TC].)

4

VERIFY IF STORED OTHER DTCs STORED

• Verify stored DTCs using the M-MDS.

• Is DTC P2088 or P2089 present?

Yes

Go to the appropriate DTC troubleshooting procedures.

No

Go to the next step.

5

INSPECT VARIABLE SWIRL SOLENOID VALVE

• Perform “VARIABLE SWIRL SOLENOID

VALVE INSPECTION”.

(See01-13-13 VARIABLE SWIRL SOLENOID

VALVE INSPECTION[L3 WITH TC].)

• Is the variable swirl solenoid valve normal?

Yes

Go to the next step.

No

Replace variable swirl solenoid valve, then go to Step 13.

6

INSPECT VARIABLE SWIRL SHUTTER VALVE

ACTUATOR

• Perform “VARIABLE SWIRL SHUTTER VALVE

ACTUATOR INSPECTION”.

(See01-13-13 VARIABLE SWIRL SHUTTER

VALVE ACTUATOR INSPECTION[L3 WITH

TC].)

• Is the variable swirl shutter valve actuator

normal?

Yes

Go to the next step.

No

Replace the intake manifold, then go to Step 13.

7

INSPECT VARIABLE SWIRL SHUTTER VALVE

SWITCH

• Perform the “VARIABLE SWIRL SHUTTER

VALVE SWITCH INSPECTION”.

(See01-13-13 VARIABLE SWIRL SHUTTER

VALVE ACTUATOR INSPECTION[L3 WITH

TC].)

• Is the variable swirl shutter valve switch

normal?

Yes

Go to the next step.

No

Replace the intake manifold, then go to Step 13.

8

VERIFY CONNECTION OF VACUUM HOSE

ROUTING

• Verify that the vacuum hoses are connected

properly.

• Are the vacuum hoses connected properly?

Yes

Go to the next step.

No

Connect the vacuum hoses properly, then go to the next

step.

1871-1U-06B(01-02).fm 179 ページ 2006年3月15日 水曜日 午前10時32分