Mazda Protege 5. Manual - part 211

CONVENTIONAL BRAKE SYSTEM

04–11–13

04–11

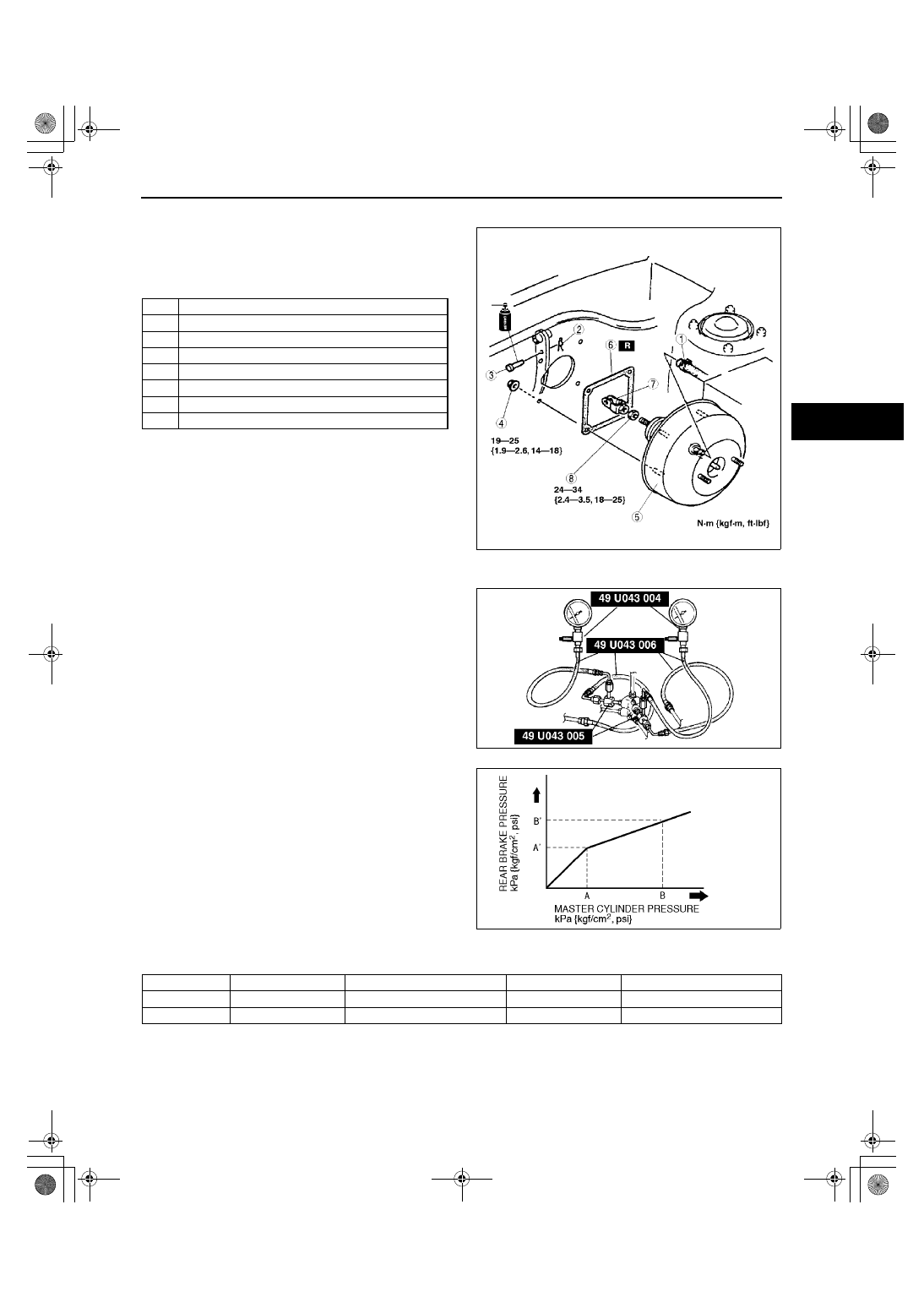

POWER BRAKE UNIT REMOVAL/INSTALLATION

A3U041143800W02

1. Remove the battery and battery cover.

2. Remove the master cylinder. (See 04–11–6

MASTER CYLINDER REMOVAL/

INSTALLATION.)

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

End Of Sie

DUAL PROPORTIONING VALVE (WITHOUT ABS) INSPECTION

A3U041143900W01

1. Connect the SSTs to the brake pipes as shown in

the figure.

2. Bleed the air from the brake system.

3. Measure the fluid pressure of the master cylinder

and the rear brake.

•

If not within the specification, replace the dual

proportioning valve.

Fluid pressure

kPa {kgf/cm

2

, psi}

End Of Sie

1

Vacuum hose

2

Snap pin

3

Clevis pin

4

Nut

5

Power brake unit

6

Gasket

7

Fork

8

Nut

X3U411WAK

X3U411WAL

A3U0411W003

Engine type

A

A'

B

B'

ZM

2,900 {30, 430}

2,900 {30, 430}

±

200 {2, 30}

5,900 {60, 850}

3,800 {39, 550}

±

300 {3, 40}

FS

3,400 {35, 500}

3,400 {35, 500}

±

300 {3, 40}

5,900 {60, 850}

4,200 {42.5, 600}

±

400 {4, 60}

1712-1U-01G(04-11).fm 13 ページ 2001年6月29日 金曜日 午前10時3分