Mazda Protege 5. Manual - part 183

CONTROL SYSTEM [FS]

01–40B–41

01–40B

5. Apply pressure then vacuum to the fuel tank

pressure sensor according to the following

procedure.

Note

•

The output voltage varies with the

measuring condition.

6. Decrease the applied pressure from +6.66 kPa

{+50 mmHg, +1.97 inHg} to –6.66 kPa {–50

mmHg, –1.97 inHg} and verify that the PCM

terminal 62 voltage decreases accordingly as

specified.

•

If not as specified, replace the fuel tank

pressure sensor.

•

If fuel tank pressure sensor is okay, but PCM terminal 62 voltage is out of specification, carry out the

“Circuit Open/Short Inspection”.

Specification

*

: Measuring condition is as follows

Input voltage: 5.0 V

Barometric pressure: 101.3 kPa {760 mmHg, 29.9 inHg} (Absolute pressure)

Barometric temperature: 30—100

°°°°

C {0—182

°°°°

F}

Circuit Open/Short Inspection

1. Remove the PCM. (See 01–40B–7 PCM REMOVAL/INSTALLATION [FS].)

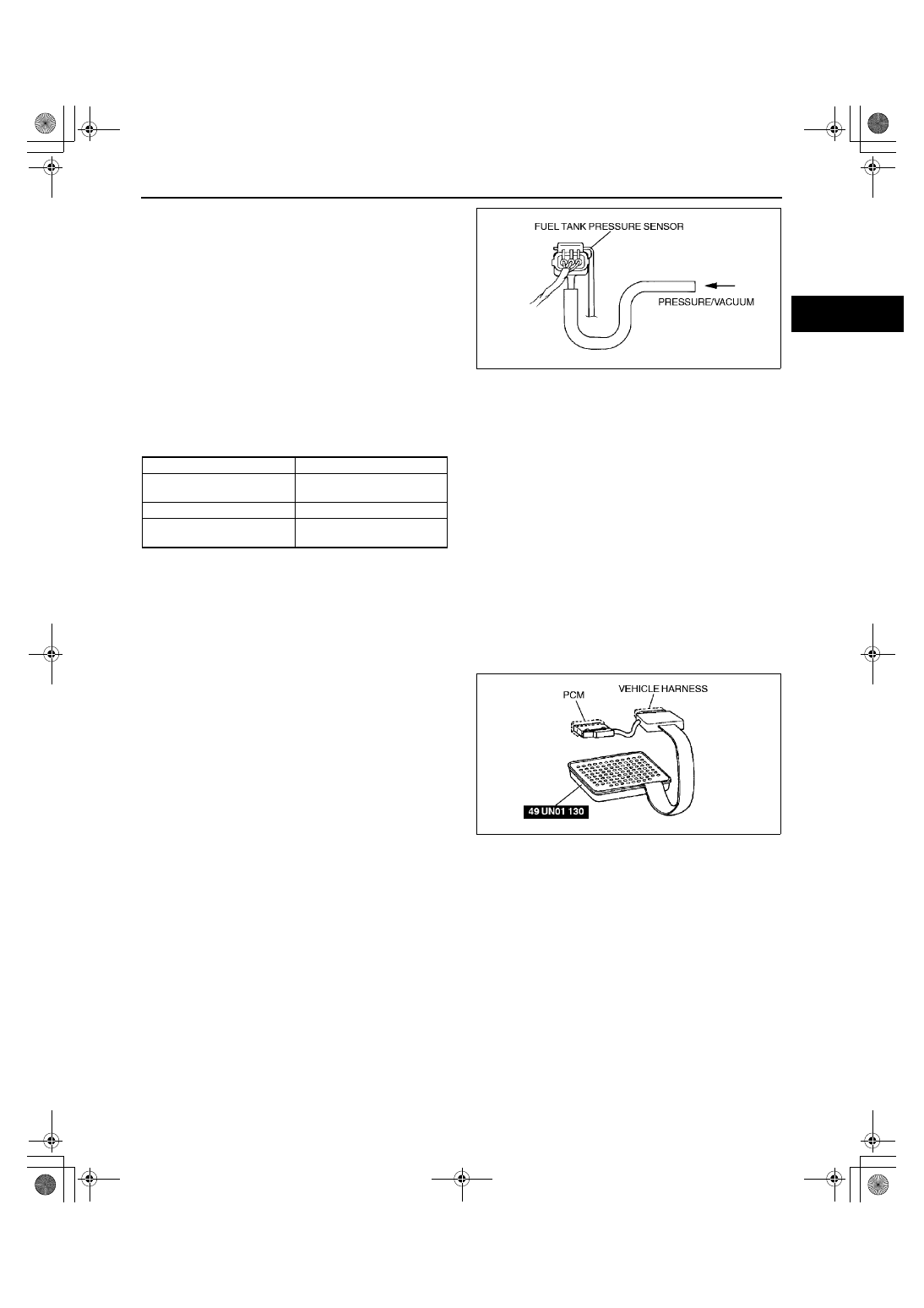

2. Connect the SST (104 Pin Breakout Box) to the

PCM as shown.

3. Tighten the connector attaching screw.

Tightening torque

7.9—10.7 N·m

{80—110 kgf·cm, 69.5—95.4 in·lbf}

4. Inspect for an open or short circuit in the following

wiring harnesses by probing the applicable

sensor and SST (104 Pin Breakout Box) terminals

with ohmmeter leads.

•

If there is an open or short circuit, repair or

replace wiring harnesses.

•

If there is no open or short circuit, replace the fuel tank pressure sensor.

Open circuit

•

Fuel tank pressure signal circuit (Fuel tank pressure sensor connector terminal B and PCM connector

terminal 62)

•

Constant voltage circuit (Fuel tank pressure sensor connector terminal C and PCM connector terminal 90)

•

GND circuit (Fuel tank pressure sensor connector terminal A and PCM connector terminal 91)

Applied pressure

Output voltage (V)*

–6.66 kPa

{–50 mmHg, –1.97 inHg}

0.45—0.55

0 kPa {0 mmHg, 0 inHg}

2.25—2.75

+6.66 kPa

{+50 mmHg, +1.97 inHg}

4.05—4.95

X3U140WB4

X3U140WB3

1712-1U-01G(01-40B).fm 41 ページ 2001年6月29日 金曜日 午前9時51分