Mazda Protege 5. Manual - part 109

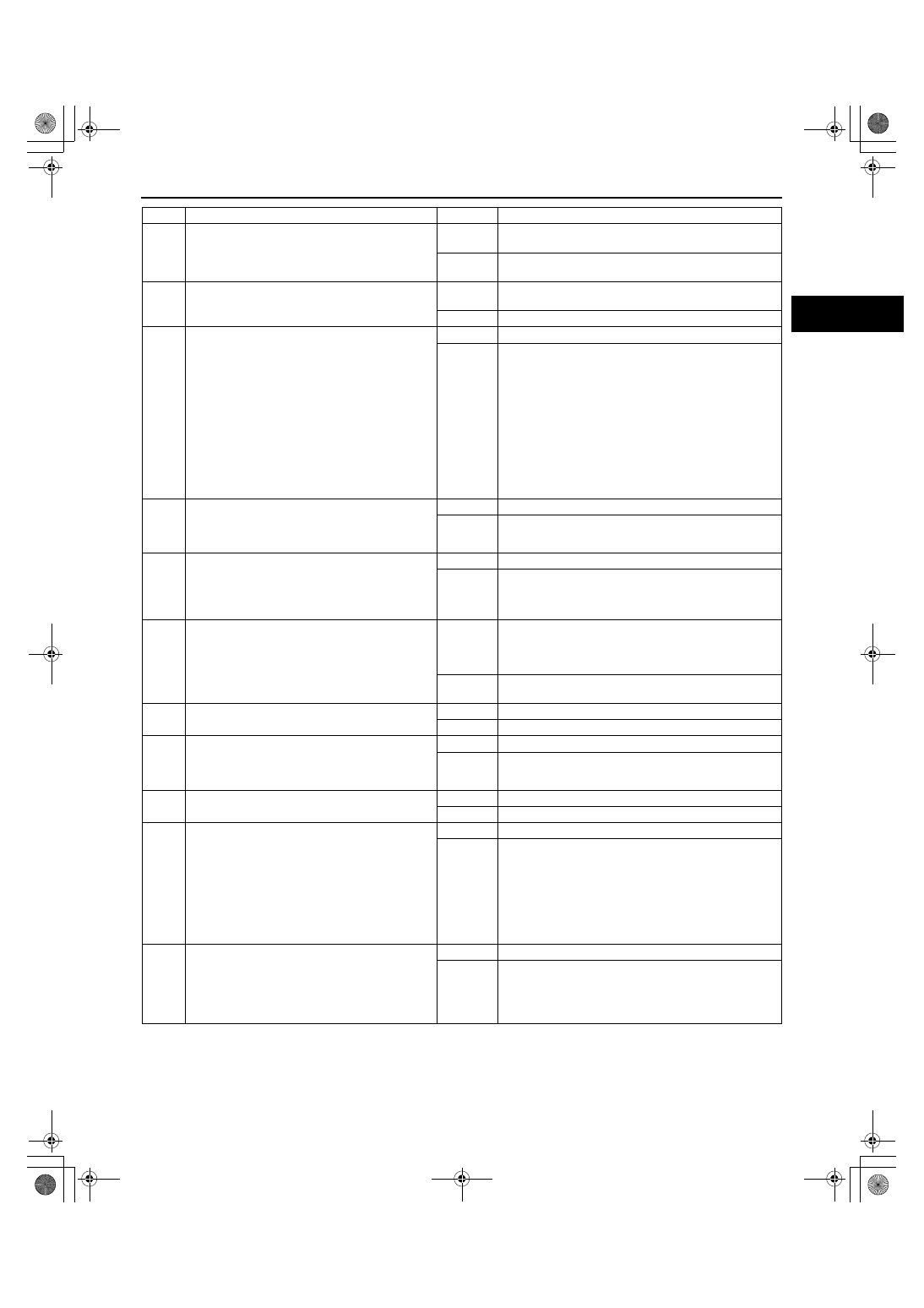

SYMPTOM TROUBLESHOOTING [ENGINE CONTROL SYSTEM (FS)]

01–03B–29

01–03B

2

•

Connect WDS or equivalent to DLC-2.

•

Turn ignition key to ON.

•

Retrieve any DTC.

•

Is “DTC” displayed?

Yes

No DTC displayed:

•

Go to next step.

No

DTC displayed:

•

Go to appropriate DTC test.

3

•

Is engine overheating?

Yes

Go to symptom troubleshooting “NO.17 COOLING

SYSTEM CONCERNS - OVERHEATING [FS].”

No

Go to next step.

4

•

Connect WDS or equivalent to DLC-2.

•

Access RPM PID, MAF PID, TP PID, and

VSS PID.

•

Drive vehicle with monitoring PIDs.

•

Are PIDs within specification?

Yes

Go to next step.

No

RPM PID:

•

Inspect CKP sensor and related wiring harness:

vibration, intermittent open/short circuit.

MAF PID:

•

Inspect for open circuit of MAF sensor and related

wiring harness intermittently.

TP PID:

•

Inspect if output signal from TP sensor changes

smoothly.

VSS PID:

•

Inspect for open circuit of VSS and related wiring

harness intermittently.

5

•

Visually inspect CKP sensor and teeth of

crankshaft pulley.

•

Are CKP sensor and teeth of crankshaft

pulley okay?

Yes

Go to next step.

No

Replace malfunctioning parts.

6

•

Measure gap between CKP sensor and teeth

of crankshaft pulley.

Gap

0.5—1.5 mm {0.020—0.059 in}

•

Is gap within specification?

Yes

Go to next step.

No

Adjust CKP sensor.

7

•

Inspect condition of spark plugs.

•

Is spark plug wet, covered with carbon or

grayish white?

Yes

Spark plug is wet or covered with carbon:

•

Inspect for fuel leakage from fuel injector.

Spark plug is grayish white:

•

Inspect for clogged fuel injector.

No

Install spark plugs on original cylinders.

Go to next step.

8

•

Remove and shake PCV valve.

•

Does PCV valve rattle?

Yes

Go to next step.

No

Replace PCV valve.

9

•

Verify that throttle lever is resting on throttle

valve stop screw and/or throttle valve orifice

plug.

•

Is lever in correct position?

Yes

Go to next step.

No

Adjust as necessary.

10

•

Are there any restrictions in the exhaust

system?

Yes

Inspect exhaust system.

No

Go to next step.

11

•

Install fuel pressure gauge between fuel filter

and fuel distributor.

•

Connect jumper wire between F/P terminal at

DLC in engine compartment and GND.

•

Turn ignition key to ON.

•

Is fuel line pressure correct with ignition key

at ON?

Fuel line pressure

270—310 kPa {2.7—3.2 kgf/cm

2

, 39—45 psi}

Yes

Go to next step.

No

Zero or low:

•

Inspect fuel pump circuit.

•

Inspect for open fuel pump relief valve.

•

Inspect for fuel leakage inside pressure regulator.

•

Inspect for clogged main fuel line.

High:

•

Inspect pressure regulator for high pressure cause.

•

Inspect for clogged fuel return line.

12

•

Visually inspect for fuel leakage at fuel

injector, O-ring, and fuel line.

•

Service as necessary.

•

Does fuel line pressure hold after ignition key

is turned to LOCK?

(See 01–14–28 Operation Inspection.)

Yes

Go to next step.

No

Inspect pressure regulator diaphragm condition.

If condition is okay, inspect fuel injector.

If condition is not okay, replace pressure regulator.

STEP

INSPECTION

RESULTS

ACTION

1712-1U-01G(01-03B).fm 29 ページ 2001年6月29日 金曜日 午前9時33分