Mazda Protege 5. Manual - part 107

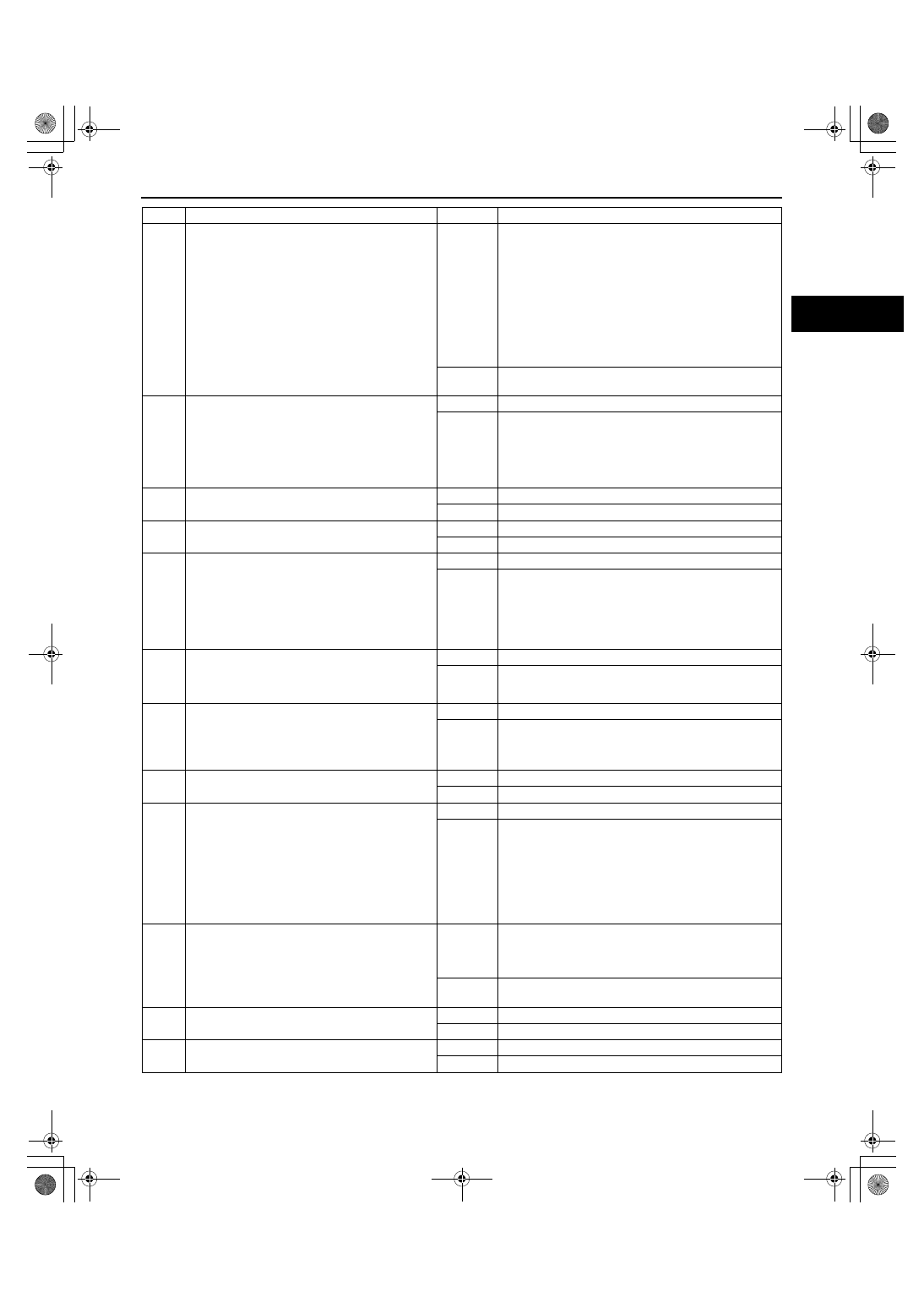

SYMPTOM TROUBLESHOOTING [ENGINE CONTROL SYSTEM (FS)]

01–03B–21

01–03B

2

•

Connect WDS or equivalent to DLC-2.

•

Turn ignition key to ON.

•

Retrieve any DTC.

•

Is “DTC” displayed?

Yes

DTC displayed:

•

Go to appropriate DTC test.

Communication error message displayed:

•

Inspect for following:

— Open circuit between main relay and PCM

terminal 71 or 97

— Open main relay GND circuit

— Main relay is stuck open.

— Open or poor GND circuit (PCM terminal 24, 51,

76, 77, or 103)

— Poor connection of vehicle body GND

No

No DTC displayed:

•

Go to next step.

3

•

Turn ignition key to LOCK.

•

Disconnect TP sensor connector.

•

Measure voltage at TP sensor connector

VREF terminal with ignition key on.

Voltage

4.5—5.5 V

•

Is voltage okay?

Yes

Go to next step.

No

Go to symptom troubleshooting “NO.30 REFERENCE

VOLTAGE [FS].”

4

•

Does engine start with throttle closed?

Yes

Go to Step 20.

No

Go to next step.

5

•

Will engine start and run smoothly at part

throttle?

Yes

Inspect IAC valve and wiring harness.

No

Go to next step.

6

•

Connect WDS or equivalent to DLC-2.

•

Access RPM PID.

•

Is RPM PID indicating engine speed when

cranking engine?

Yes

Go to next step.

No

Inspect for following:

•

Open or short circuit in CKP sensor

•

Open or short circuit between CKP sensor and

PCM terminal 21 or 22

•

Open or short circuit in CKP sensor harnesses

If CKP sensor and harness are okay, go to next step.

7

•

Visually inspect CKP sensor and teeth of

crankshaft pulley.

•

Are CKP sensor and teeth of crankshaft

pulley okay?

Yes

Go to next step.

No

Replace malfunctioning parts.

8

•

Measure gap between CKP sensor and teeth

of crankshaft pulley.

Gap

0.5—1.5 mm {0.020—0.059 in}

•

Is gap within specification?

Yes

Go to next step.

No

Adjust CKP sensor.

9

•

Inspect for cracks on high-tension leads.

•

Are there any cracks, on high-tension leads?

Yes

Repair suspected high-tension leads.

No

Go to next step.

10

•

Is strong blue spark visible at each

disconnected high-tension lead during

engine cranking ?

Yes

Go to next step.

No

Inspect for following:

•

Open or short circuit in ignition coil

•

Open circuit in high-tension leads

•

Open circuit between ignition coil connector GND

terminal and GND

•

Open circuit between ignition key and ignition coil

•

Open circuit between ignition coil and PCM

terminal 26 or 52

11

•

Inspect condition of spark plugs.

•

Is spark plug wet, covered with carbon or

grayish white?

Yes

Spark plug is wet or covered with carbon:

•

Inspect for fuel leakage from injector.

Spark plug is grayish white:

•

Inspect for clogged fuel injector.

No

Install spark plugs on original cylinders.

Go to next step.

12

•

Remove and shake PCV valve.

•

Does PCV valve rattle?

Yes

Go to next step.

No

Replace PCV valve.

13

•

Is there any restriction in exhaust system?

Yes

Inspect exhaust system.

No

Go to next step.

STEP

INSPECTION

RESULTS

ACTION

1712-1U-01G(01-03B).fm 21 ページ 2001年6月29日 金曜日 午前9時33分