Mazda 5. Manual - part 35

05–17–60

AUTOMATIC TRANSAXLE

Snap ring sizes

(9) Install the selected snap ring and perform steps (2) to (7) again. Verify that the calculated value satisfies the

clearance specification.

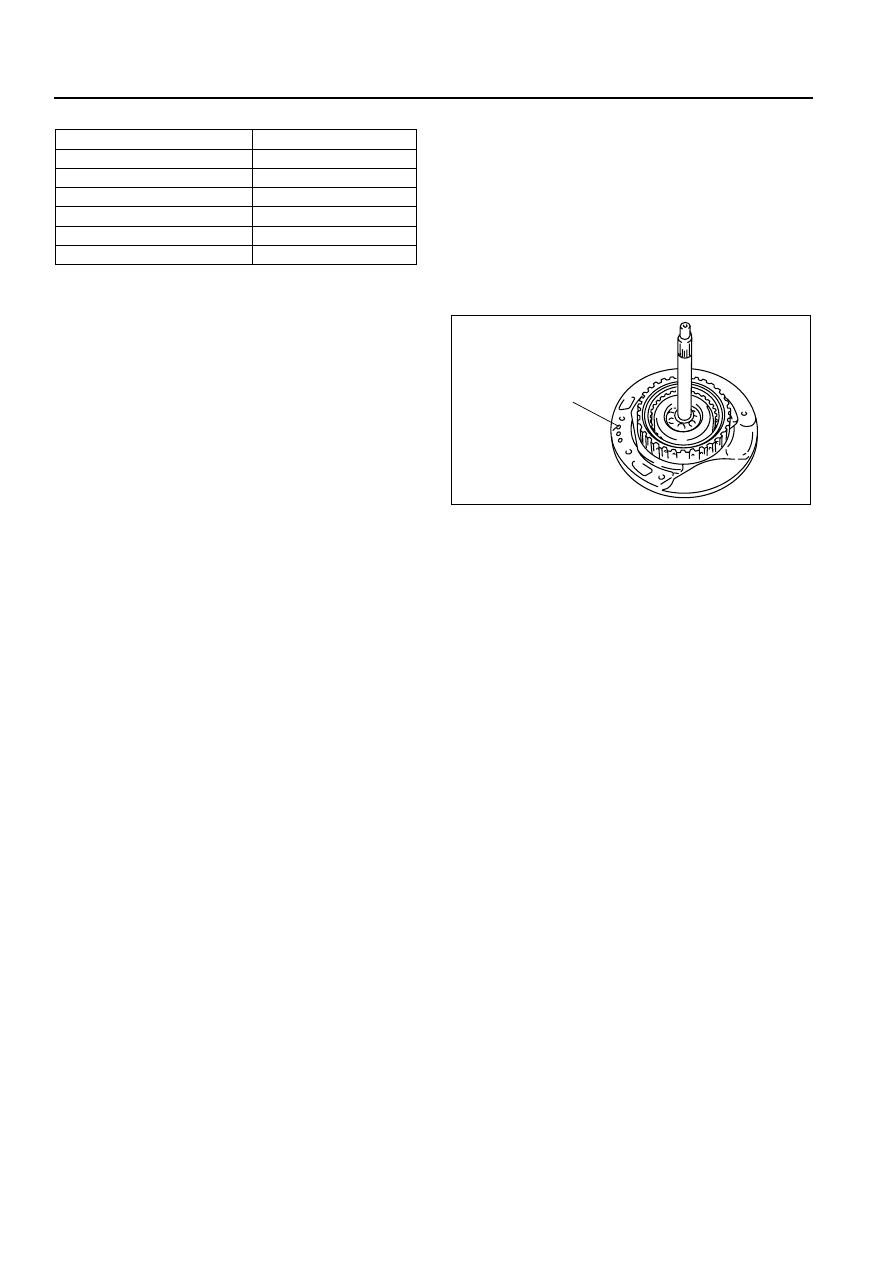

16. Inspect the forward clutch operation.

(1) Install the forward clutch drum and turbine

shaft to the oil pump.

(2) Inspect the forward clutch operation by

applying compressed air as shown.

Air pressure

392—441 kPa {4.0—4.5 kgf/cm

2

, 57—63 psi}

17. Install the forward clutch hub.

End Of Sie

CLUTCH COMPONENT DISASSEMBLY/ASSEMBLY

B3E051719500A02

1. Perform the preinspection before disassembly. (See 05–17–125 Clutch Component Preinspection.)

2. Disassemble in the order indicated in the table.

3. Assemble in the reverse order of disassembly.

Range mm {in}

Snap ring sizes mm {in}

2.750—2.950 {0.108—0.116}

1.2 {0.047}

2.950—3.150 {0.116—0.124}

1.4 {0.055}

3.150—3.350 {0.124—0.132}

1.6 {0.063}

3.350—3.550 {0.132—0.140}

1.8 {0.071}

3.550—3.750 {0.140—0.148}

2.0 {0.079}

3.750—3.950 {0.148—0.155}

2.2 {0.087}

FORWARD CLUTCH

FLUID PASSAGE

B3E0517A117