Mazda 5. Manual - part 18

GENERAL INFORMATION

00–00–3

00

Advisory Messages

• You will find several Warnings, Cautions, Notes, Specifications and Upper and Lower Limits in this

manual.

Warning

• A Warning indicates a situation in which serious injury or death could result if the warning is ignored.

Caution

• A Caution indicates a situation in which damage to the vehicle or parts could result if the caution is ignored.

Note

• A Note provides added information that will help you to complete a particular procedure.

Specification

• The values indicate the allowable range when performing inspections or adjustments.

Upper and lower limits

• The values indicate the upper and lower limits that must not be exceeded when performing inspections or

adjustments.

End Of Sie

UNITS

B3E000000002A01

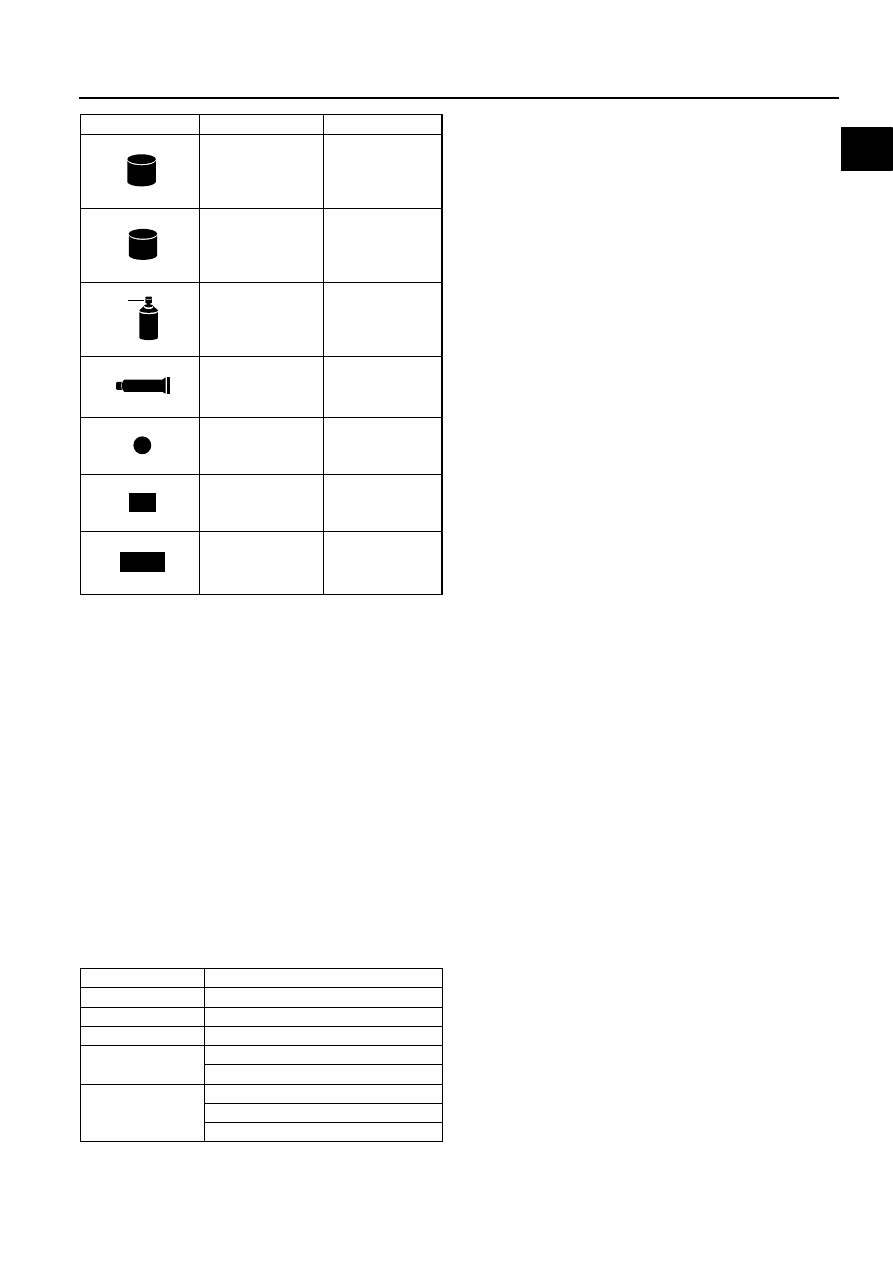

Apply brake fluid

New appropriate

brake fluid

Apply automatic

transaxle/

transmission fluid

New appropriate

automatic

transaxle/

transmission fluid

Apply grease

Appropriate

grease

Apply sealant

Appropriate

sealant

Apply petroleum

jelly

Appropriate

petroleum jelly

Replace part

O-ring, gasket,

etc.

Use SST or

equivalent

Appropriate tools

Symbol

Meaning

Kind

BRAKE

BRAKE

FLUID

A

ATF

TF

GREASEGREASE

SEALANT

P

R

SST

Electric current

A (ampere)

Electric power

W (watt)

Electric resistance

ohm

Electric voltage

V (volt)

Length

mm (millimeter)

in (inch)

Negative pressure

kPa (kilo pascal)

mmHg (millimeters of mercury)

inHg (inches of mercury)