Mazda 5. Manual - part 3

GENERAL INFORMATION

00–00–9

00

End Of Sie

NEW STANDARDS

B3E000000003201

• Following is a comparison of the previous standard and the new standard.

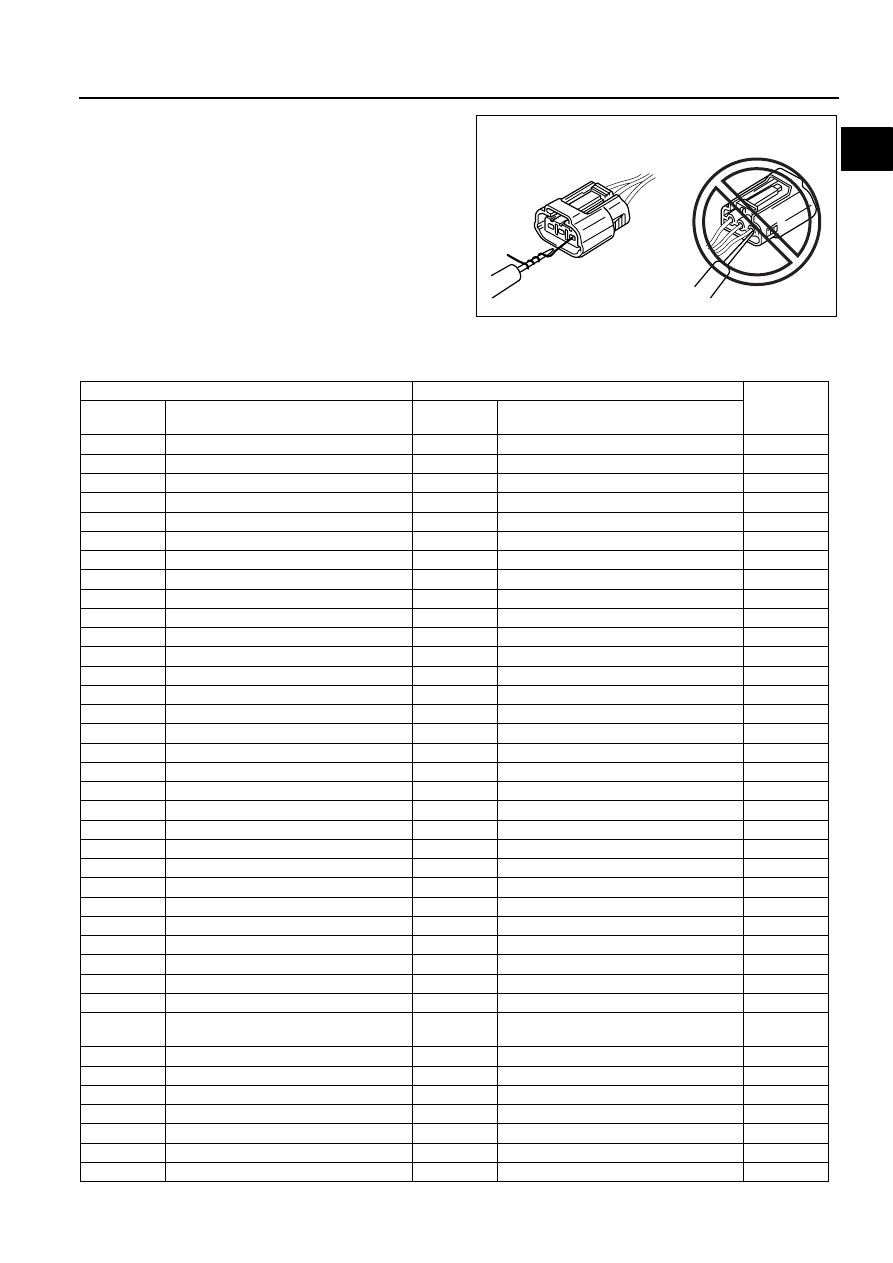

GOOD

NO GOOD

CHU0000W012

New Standard

Previous Standard

Remark

Abbrevi-

ation

Name

Abbrevi-

ation

Name

AP

Accelerator Pedal

—

Accelerator Pedal

ACL

Air Cleaner

—

Air Cleaner

A/C

Air Conditioning

—

Air Conditioning

BARO

Barometric Pressure

—

Atmospheric Pressure

B+

Battery Positive Voltage

Vb

Battery Voltage

—

Brake Switch

—

Stoplight Switch

—

Calibration Resistor

—

Corrected Resistance

#6

CMP sensor Camshaft Position Sensor

—

Crank Angle Sensor

CAC

Charge Air Cooler

—

Intercooler

CLS

Closed Loop System

—

Feedback System

CTP

Closed Throttle Position

—

Fully Closed

CPP

Clutch Pedal Position

—

Idle Switch

CIS

Continuous Fuel Injection System

—

Clutch Position

CS sensor

Control Sleeve Sensor

CSP sensor Control Sleeve Position Sensor

#6

CKP sensor Crankshaft Position Sensor

—

Crank Angle Sensor 2

DLC

Data Link Connector

—

Diagnosis Connector

DTM

Diagnostic Test Mode

—

Test Mode

#1

DTC

Diagnostic Trouble Code(s)

—

Service Code(s)

DI

Distributor Ignition

—

Spark Ignition

DLI

Distributorless Ignition

—

Direct Ignition

EI

Electronic Ignition

—

Electronic Spark Ignition

#2

ECT

Engine Coolant Temperature

—

Water Thermo

EM

Engine Modification

—

Engine Modification

—

Engine Speed Input Signal

—

Engine RPM Signal

EVAP

Evaporative Emission

—

Evaporative Emission

EGR

Exhaust Gas Recirculation

—

Exhaust Gas Recirculation

FC

Fan Control

—

Fan Control

FF

Flexible Fuel

—

Flexible Fuel

4GR

Fourth Gear

—

Overdrive

—

Fuel Pump Relay

—

Circuit Opening Relay

#3

FSO

solenoid

Fuel Shut Off Solenoid

FCV

Fuel Cut Valve

#6

GEN

Generator

—

Alternator

GND

Ground

—

Ground/Earth

HO2S

Heated Oxygen Sensor

—

Oxygen Sensor

With heater

IAC

Idle Air control

—

Idle Speed Control

—

IDM Relay

—

Spill Valve Relay

#6

—

Incorrect Gear Ratio

—

—

—

Injection Pump

FIP

Fuel Injection Pump

#6