Isuzu Trooper (1998-2002 year). Manual - part 687

7A–40

AUTOMATIC TRANSMISSION (4L30–E)

Solenoid (Adapter Case Valve Body)

Removal

1. Raise the vehicle and support it on jack stands.

2. Disconnect battery ground cable.

3. Drain fluid.

4. Remove adapter case oil pan twelve fixing 10 mm

screws, adapter case oil pan, and gasket.

NOTE: Oil pan still contains transmission fluid. Place a

large drain container under the oil pan and drain the fluid

carefully.

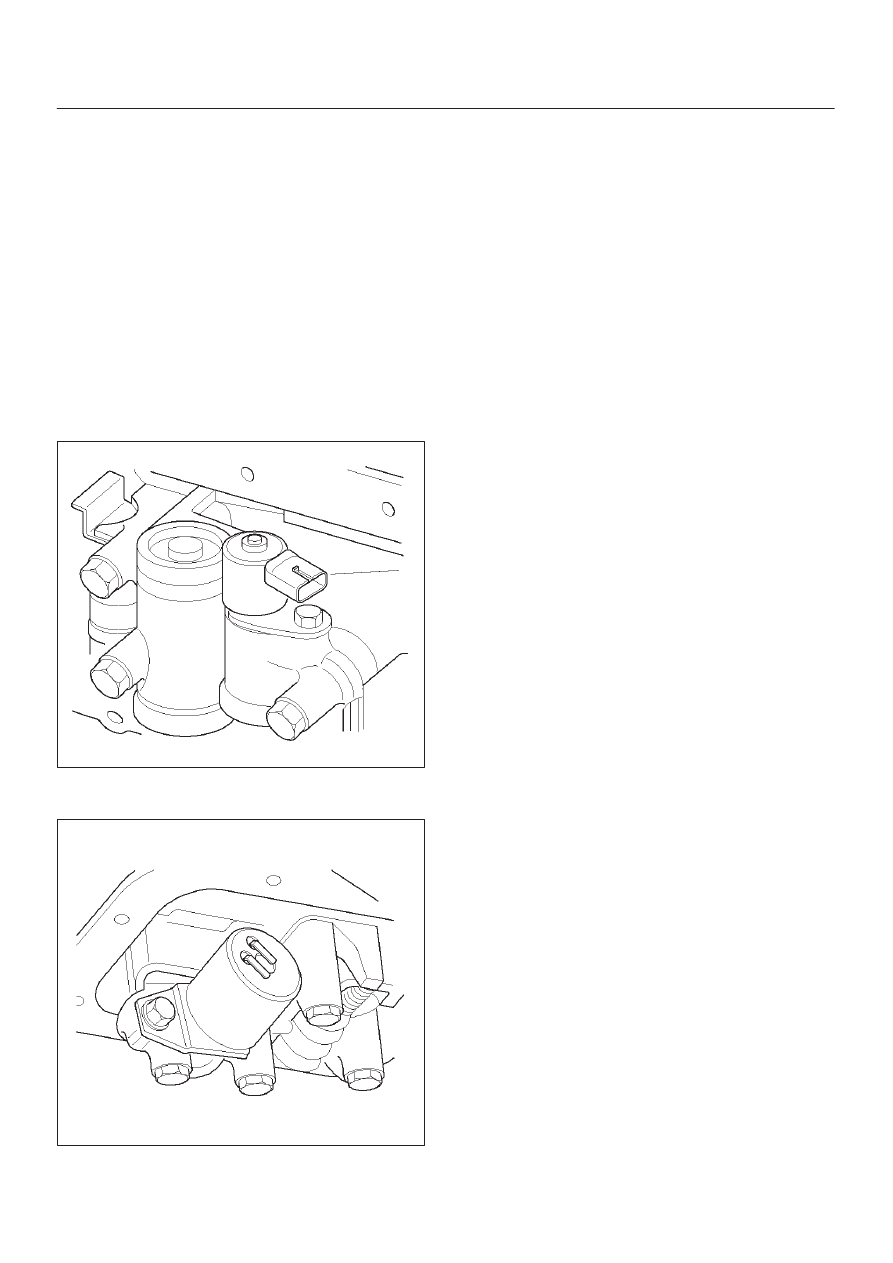

5. Disconnect wiring harness from force motor solenoid

and converter clutch PWM solenoid. Pull only on

connectors, not on wiring harness.

6. Remove 11 mm bolt, bracket and converter clutch

PWM solenoid with two O–rings.

210RY001

7. Remove 11 mm bolt, retainer, and force motor

solenoid.

210RW009

Installation

1. Install force motor solenoid, retainer, and 11 mm bolt

to adapter case valve body. Tighten the bolt to the

specified torque.

Torque: 10 N

•

m (1.0 kg·m/87 Ib in)

2. Install converter clutch PWM solenoid with two O–

rings, bracket, and 11 mm bolt to adapter case valve

body. Tighten the bolt to the specified torque.

Torque : 10 N

•

m (1.0 kg·m/87 Ib in)

3. Connect wiring harness assembly to solenoids.

4. Install adapter case oil pan, new gasket, and twelve

10 mm screws. Tighten the screws to the specified

torque.

Torque : 11 N

•

m (1.1 kg·m/96 Ib in)

5. Fill transmission through overfill screw hole oil pan,

using ATF DEXRON

–III. Refer to Changing

Transmission Fluid in this section.

6. Connect battery ground cable.