Isuzu Trooper (1998-2002 year). Manual - part 651

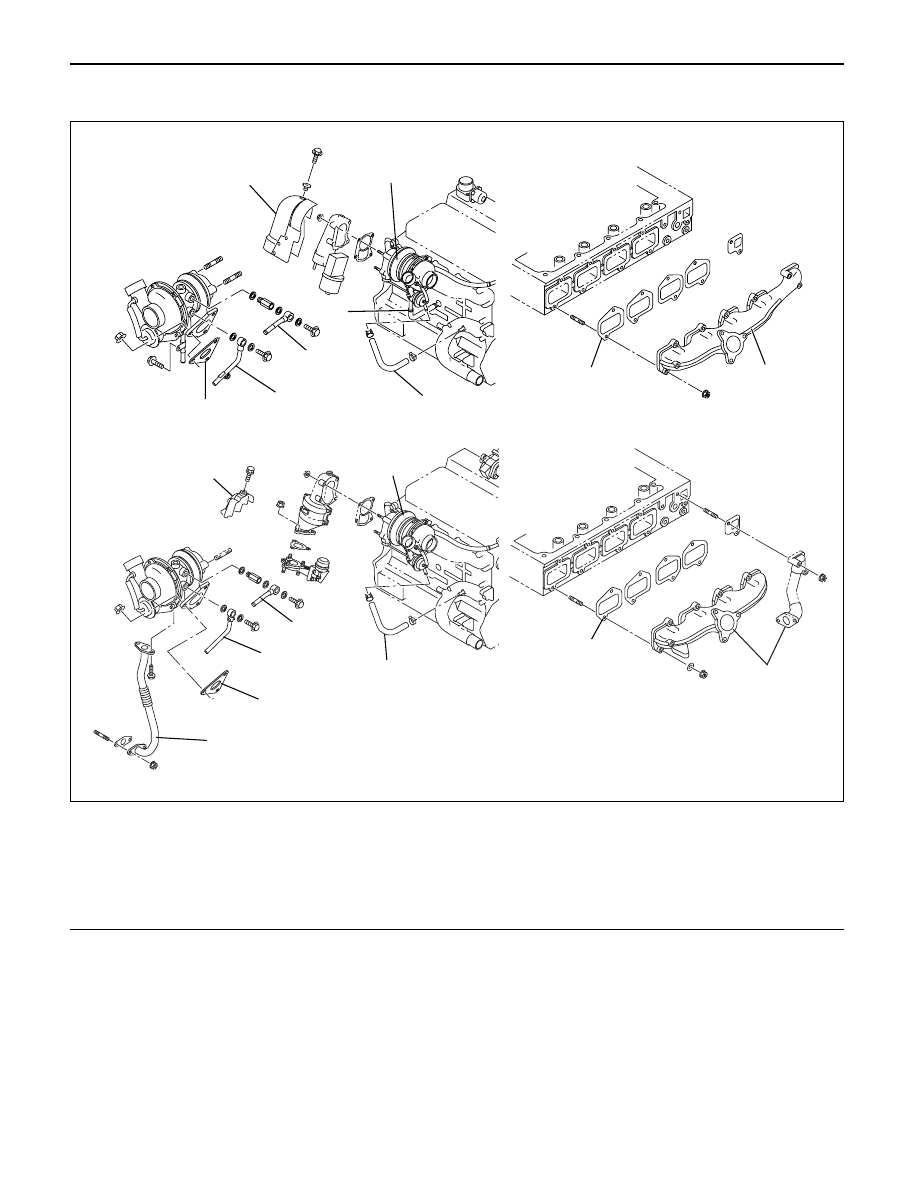

6J – 4 INDUCTION

TURBOCHARGER

9

5

9

8

For Europe

8

7

5

6

3

2

1

4

7

4

2

1

3

6

Legend

(1)

Exhaust Manifold

(2)

Gasket

(3)

Turbocharger Assembly

(4)

Water Hose

(5)

Water Hose

(6)

Heat Protector

(7)

Oil Pipe

(8)

Oil Pipe

(9)

Gasket

025R200004