Isuzu Trooper (1998-2002 year). Manual - part 649

6G – 6 ENGINE LUBRICATION

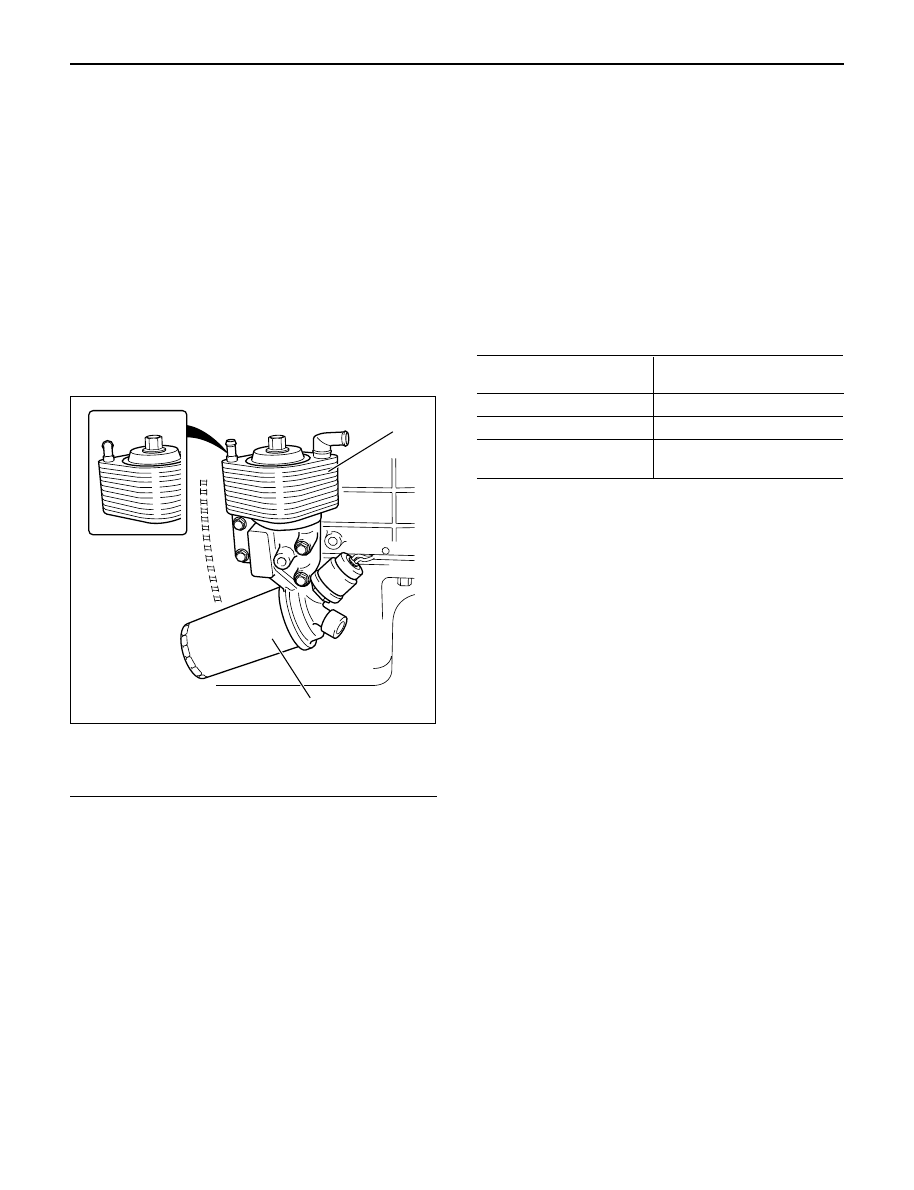

OIL COOLER ASSEMBLY

REMOVAL

1. Disconnect battery ground cable.

2. Drain engine coolant.

3. Remove front exhaust pipe.

4. Remove heat protector.

5. Remove exhaust valve assembly.

6. Oil cooler assembly.

1) Remove water hose from water inlet and outlet

side.

2) Cloth should be put under the oil cooler to

prevent oil from flowing out.

3) Loosen fixing bolt then remove oil cooler

assembly.

Legend

(1) Oil cooler assembly

(2) Oil filter assembly

INSPECTION AND REPAIR

1. Inspect for corrosion, wear, and breaks on the oil

cooler core.

2. If a problem is found on the oil cooler core, the oil

cooler assembly must be replaced.

INSTALLATION

1. Oil cooler assembly

1) Tighten oil cooler fixing bolt to the specified

torque and install water hoses.

Torque: 29 N·m (3.0 kg·m / 22 lb ft)

2. Install exhaust valve assembly to turbocharger

assembly and tighten to the specified torque.

Torque: 27 N·m (2.8 kg·m / 20 lb ft)

3. Install front exhaust pipe to the exhaust valve.

Torque:

67 N·m (6.8 kg·.m / 49 lb ft)

(At exhaust valve side)

43 N·m (4.4 kg·m / 32 lb ft)

(At center exhaust pipe side)

4. Install heater protector.

5. Fill engine coolant.

6. Connect battery ground cable.

7. Start engine and carefully check for leakage of oil

and coolant.

OIL COOLER SPECIFICATIONS

Cooling method

Water cooled

Multi plate type

Heat exchange Area

0.323 m

2

Heat exchange capacity

>11,300 kcl/h

Relief Valve opening

245 Kpa (2.5 kg/cm

2

/36 psi)

pressure

OIL FILTER

REMOVAL

1. Put container under the oil filter to prevent oil from

the oil filter from flowing out.

2. Use filter wrench to remove oil filter.

Filter wrench: 5-8840-0203-0

INSTALLATION

1. Apply engine oil thinly to oil filter O-ring.

2. Tighten oil filter by hand until O-ring comes in

contact with the sealing surface.

3. Use filter wrench to tighten oil filter one turn and 1/8

turn.

4. Start engine and carefully check for oil leakage from

oil filter.

SUB OIL FILTER

The sub oil filter requires no servicing until the

replacement interval is reached.

The element is designed to provide special filtering

efficiency until it becomes due for replacement.

It is recommended to check and replace the sub oil filter

when the engine is being overhauled or if it is broken

inside the engine.

For Europe

1

2

050R200001