Isuzu Trooper (1998-2002 year). Manual - part 612

6E–96

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0198 (Flash DTC 16)

Oil Temp Sensor High Voltage

060RW129

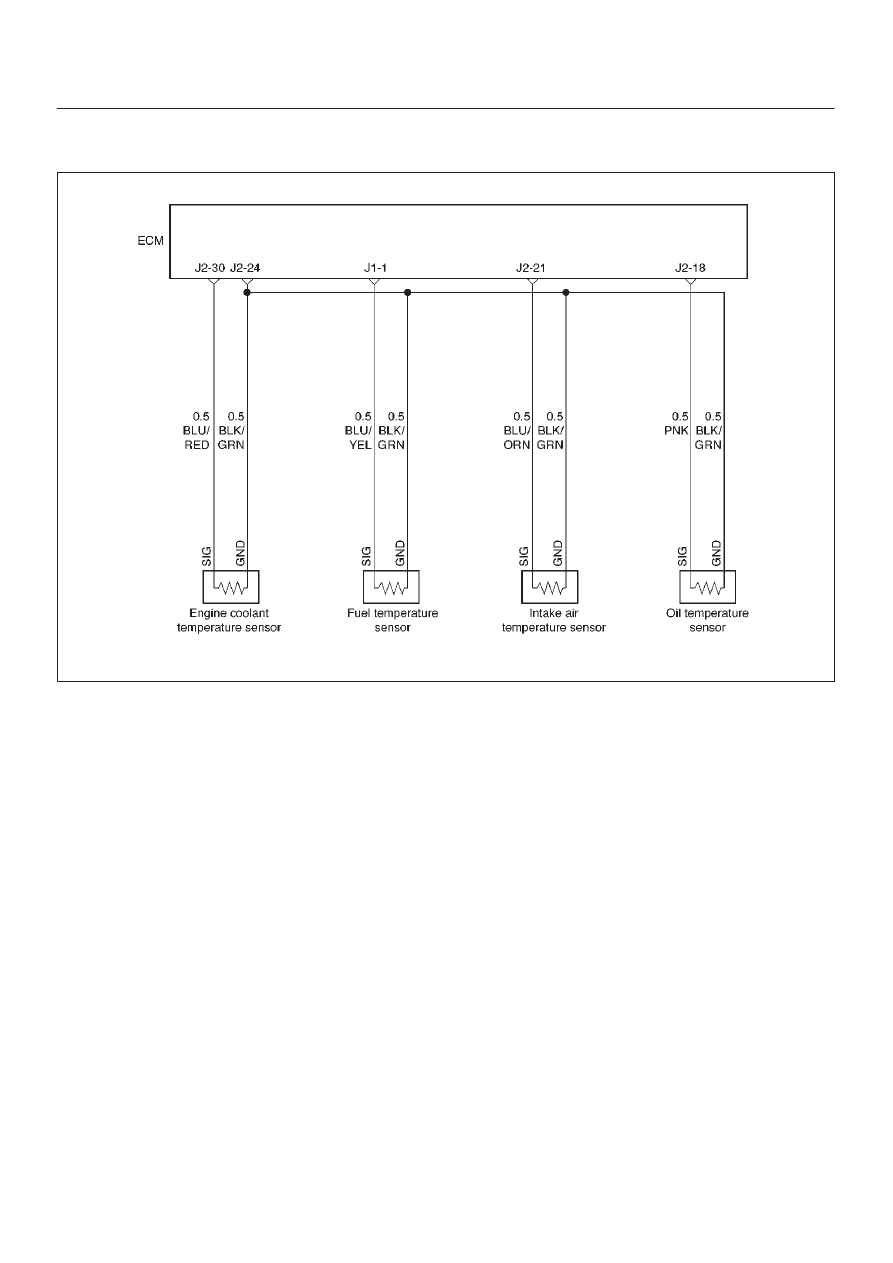

Circuit Description

The engine oil temperature (OT) sensor is a thermistor

mounted in the oil rail. The Engine Control Module ECM

applies a voltage (about 5 volts) through a pull-up resistor

to the ECT signal circuit. When the engine oil is cold, the

sensor (thermistor) resistance is high, therefore the ECM

will measure a high signal voltage. As the engine oil

warms, the sensor resistance becomes lower, and the OT

signal voltage measured at the ECM drops.

Action Taken When the DTC Sets

D

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

D

DTC P0198 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

D

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

D

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

OT display on the Tech 2 while moving connectors and

wiring harnesses related to the OT sensor. A change

in the OT display will indicate the location of the fault.

If DTC P0198 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently.