Isuzu Trooper (1998-2002 year). Manual - part 586

6D – 18 ENGINE ELECTRICAL

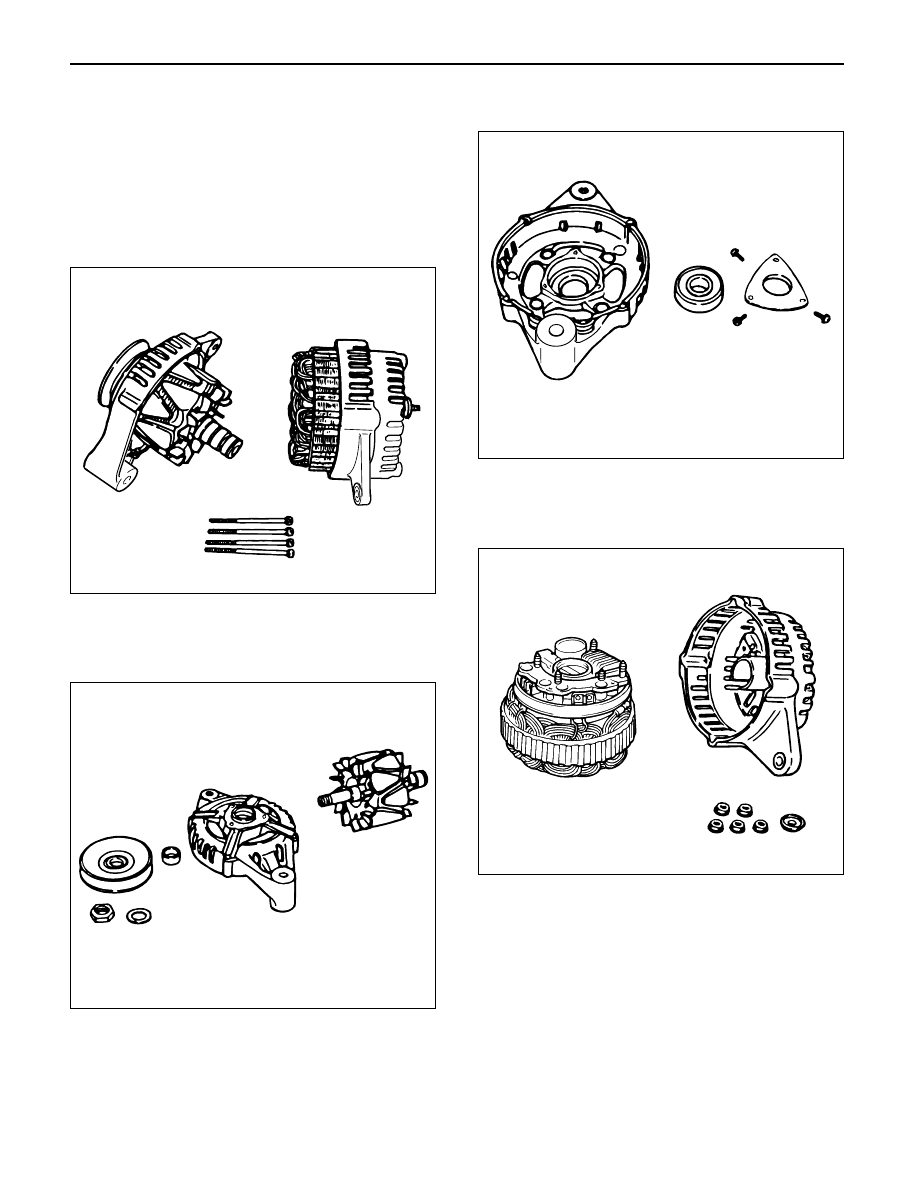

DISASSEMBLY

1. Remove the through bolt.

Insert the tip of a pry bar into the gaps between the

front cover and the stator core.

Pry apart and separate the front cover, rotor, the

rear cover and stator.

NOTE: Take care not to scratch or otherwise damage

the stator coil with pry bar.

2. Clamp the rotor in a vise and then remove the nut

and pulley.

3. Remove the rotor assembly from front cover.

4. Remove screws with bearing retainer from front

cover and remove bearing.

5. Remove the mounting nuts holding the “B ”

terminal, the diode, and the brush holder.

6. Separate the rear cover from the stator.

F06RT021

F06RT022

F06RT023

F06RT024