Isuzu Trooper (1998-2002 year). Manual - part 584

6D – 10 ENGINE ELECTRICAL

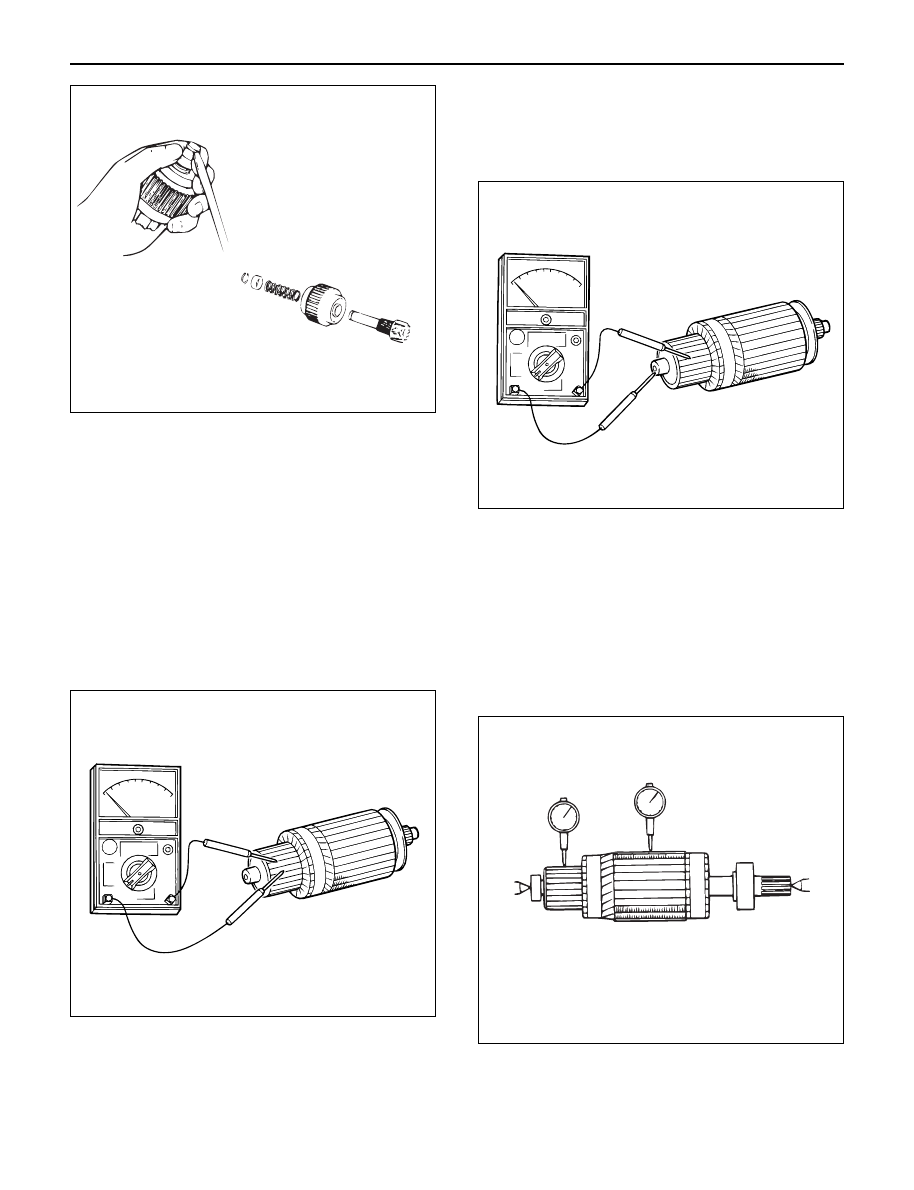

INSPECTION AND REPAIR

Repair or replace necessary parts if extreme wear or

damage is found during inspection.

Armature

1) Measure the outer diameter of commutator, and

replace with a new one if it is out of the limit.

Standard: 38.0 mm (1.50 in)

Limit: 36.5 mm (1.44 in)

2) Check for continuity between commutator and

segments. Replace commutator if there is no

continuity (i.e., disconnected).

3) Check for continuity between commutator and

shaft. Also, check for continuity between

commutator and armature core, armature core and

shaft. Replace commutator if there is continuity

(i.e., internally grounded).

4) Measure runout of armature core and commutator

with a dial gage. Repair or replace, if it exceeds the

limit.

Armature

Standard: 0.05 mm (0.002 in) Max.

Limit: 0.1 mm (0.004 in)

Commutator

Standard: 0.05 mm (0.002 in) Max.

Limit: 0.1 mm (0.004 in)

065RW041

065RS015

065RS016

045RW045