Isuzu Trooper (1998-2002 year). Manual - part 580

6C – 16 ENGINE FUEL

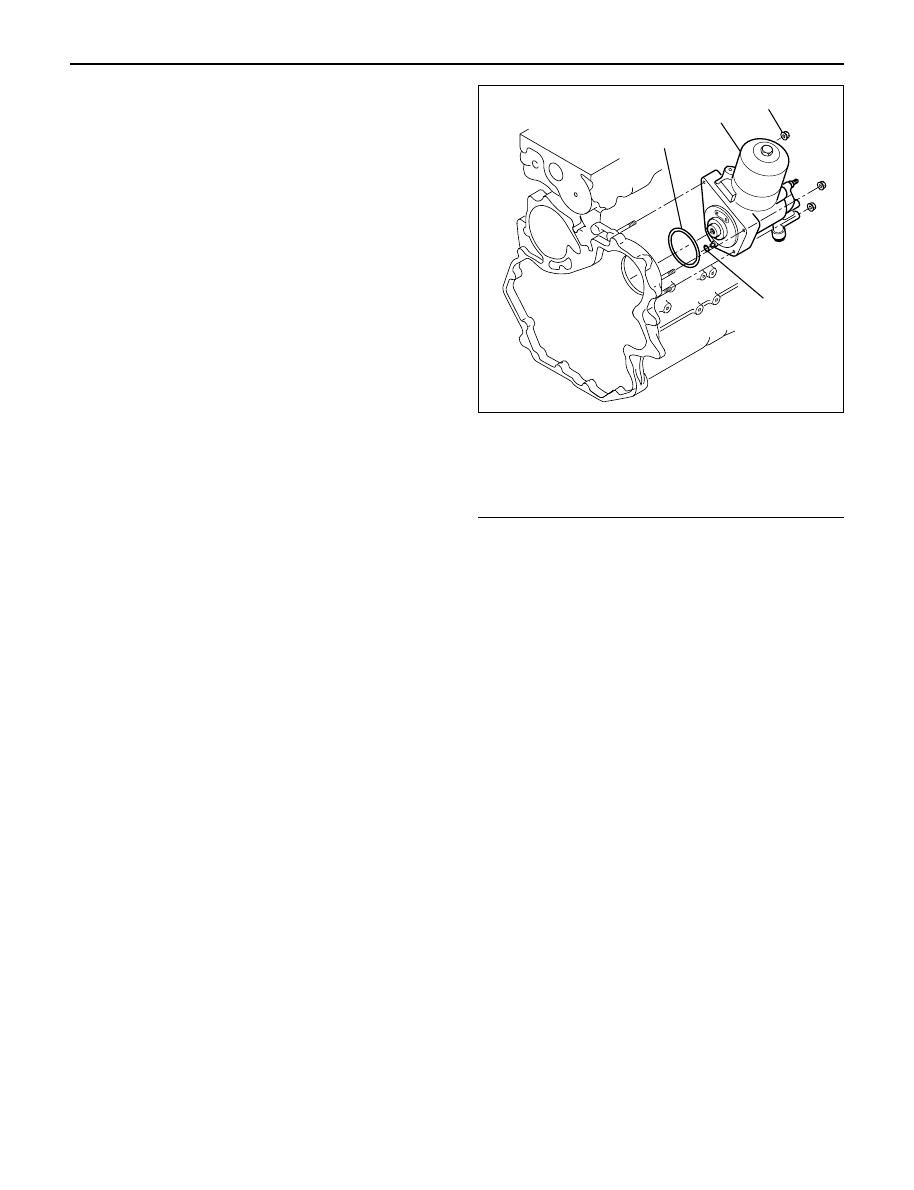

12. Remove high pressure oil pump

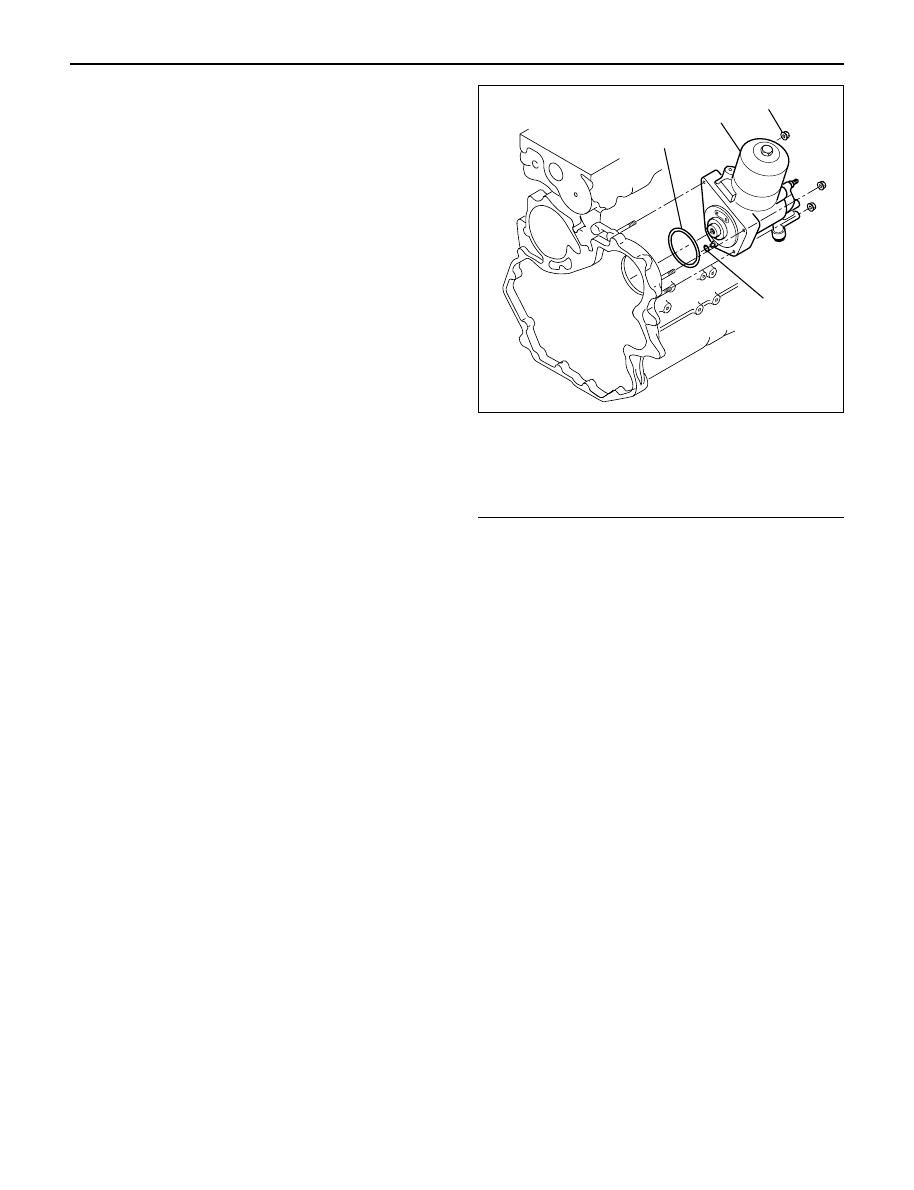

13. Remove high pressure oil pump assembly

Legend

(1) O-ring

(2) High pressure oil pump

(3) Nut

(4) O-ring

1

2

4

3

040RW007

|

|

|

6C – 16 ENGINE FUEL 12. Remove high pressure oil pump Legend (1) O-ring 1 2 4 3 040RW007 |