Isuzu Trooper (1998-2002 year). Manual - part 576

6B – 12 ENGINE COOLING

Torque:

For A.C. Generator fixing bolt

40 N·m (4.1 kg·m/30 lb ft)

For Adjusting plate fixing bolt

24 N·m (2.4 kg·m/17 lb ft)

For Adjusting plate lock bolt

20 N·m (2.0 kg·m/14 lb ft)

2) Adjust the A/C compressor drive belt by tightening

the belt tensioner bolt.

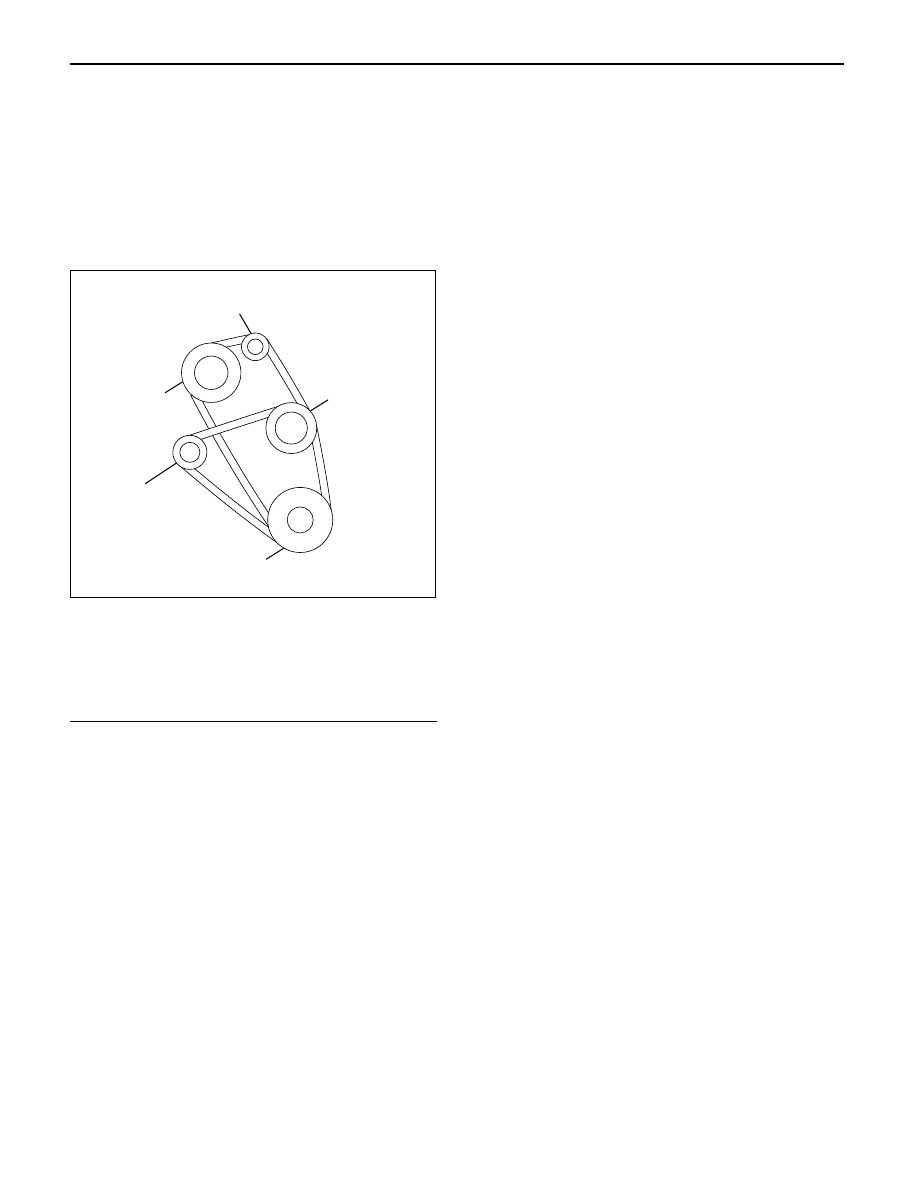

Legend

(1) Crankshaft Pulley

(2) A.C. Generator Pulley

(3) Cooling Fan Pulley

(4) A/C Compressor Pulley

(5) Belt Tensioner Pulley

5

3

2

4

1

012RW110