Isuzu Trooper (1998-2002 year). Manual - part 574

6B – 4 ENGINE COOLING

ANTI-FREEZE SOLUTION

•

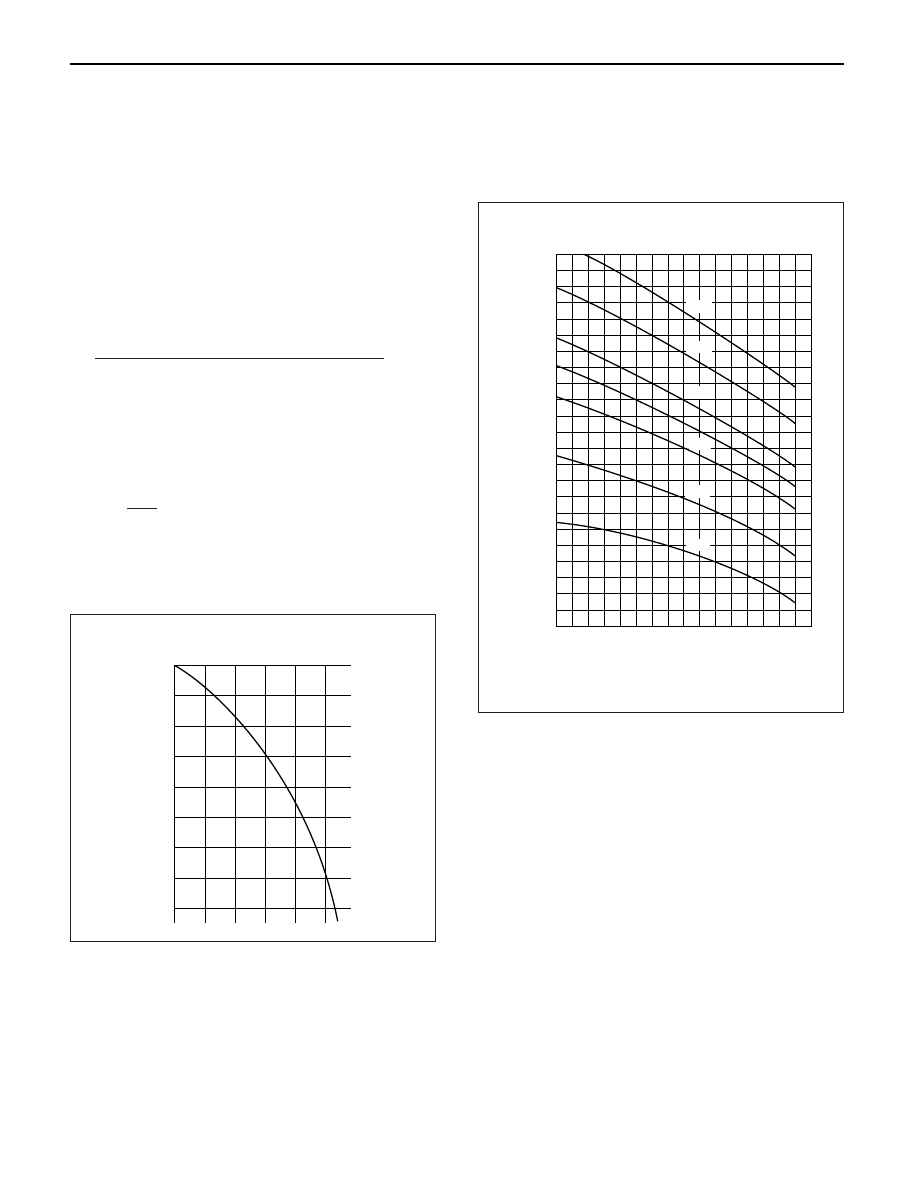

Relation between Mixing ratio and Freezing point

Freezing temperature of the engine coolant varies

with the ratio of anti-freeze solution in water.

Proper mixing ratio can be determined by refering

to the chart. Supplemental inhibitors or additives

claiming to increase cooling capability that have not

been specifically approved by Isuzu are not

recommended for addition to the cooling system.

•

Calculation of mixing ratio

Mixing ratio (%)

=

Anti-freeze solution (Lit/qt.)

×

100

Anti-freeze solution (Lit/qt.) + Water (Lit/qt.)

For example

In case total coolant capacity = 10

l

It is necessary to mix about 35% anti-freeze

solution at ambient temperature minus 20°C.

Capacity of anti-freeze solution:

35

×

10 = 3.5

l

100

Water capacity: 10

l

– 3.5

l

= 6.5

l

Therefore, you prepare the water 6.5

l

and anti-

freeze solution 3.5

l

, then mix them to get total

10

l

coolant.

•

Mixing ratio

Check the specific gravity of engine coolant in the

cooling system in temperature ranges from 0° C to

50° C using a suction type hydrometer, then

determine the density of the coolant by referring to

the table at below.

-10

10

0

Freezing T

emperature(

°

C)

20

30

Antifreeze Solution Density(%)

40

50

-20

-30

-40

B06RW018

1,100

20

10

30

40

60%

50%

40%

20%

10%

30%

Antifreeze Solution Temperature(

°

C)

50

60

70

0

Specific Gravity

1,090

1,080

1,070

1,060

1,050

1,040

1,030

1,020

1,010

1,000

B06RW017