Content .. 1078 1079 1080 1081 ..

Isuzu Trooper (1998-2002 year). Manual - part 1080

SUPPLEMENTAL RESTRAINT SYSTEM

9J–7

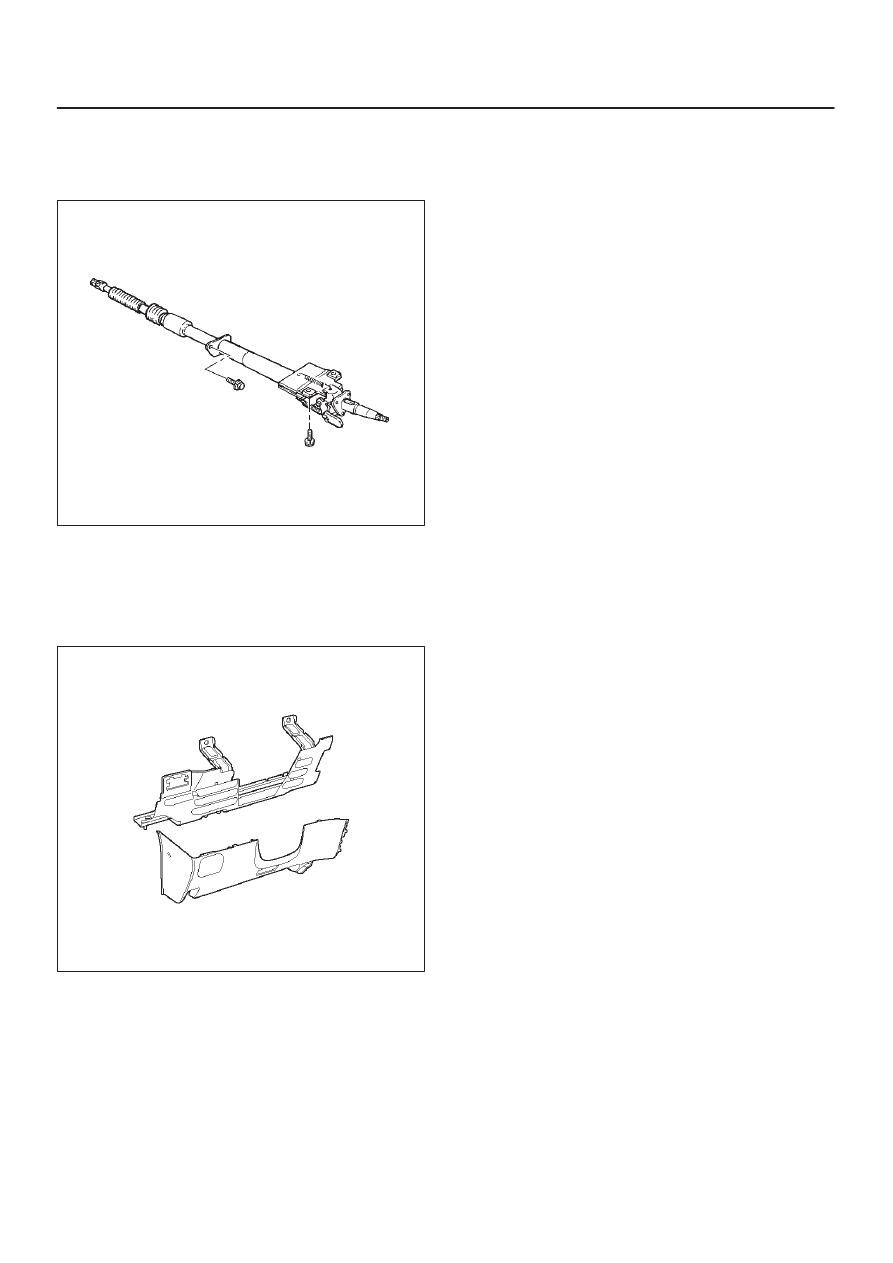

Steering Column

The steering column absorbs energy and is designed to

compress in a frontal crash to decrease the chance of

injury to the driver.

431RW019

Knee Bolster

The knee bolsters are used to absorb energy to protect

knees and control the forward movement of the vehicle’s

front seat occupants during a frontal crash, by limiting leg

movement.

740RT015

Definitions

Air Bag

An inflatable cloth cushion designed to deploy in certain

frontal crashes. It supplements the protection offered by

the seat belts by distributing the impact load more evenly

over the vehicle occupant’s head and torso.

Asynchronous

Performed in a nonperiodic fashion, (i.e., no defined time

or interval).

B+

Battery voltage, (B+) The voltage available at the battery

at the time of the indicated measurement. With the key

“ON” and the engine not running, the system voltage will

likely be between 12 and 12.5 volts. At idle, the voltage

may be 14 to 16 volts. The voltage could be as low as 10

volts during engine cranking.

Bulb Check

The SDM will cause the “AIR BAG” warning lamp to turn

on 3.5 seconds and then go “OFF” whenever the ignition

switch transitions to the ON position from any other

ignition switch position and no malfunctions are detected.

“Continuous Monitoring”

Tests performed by the SDM on the SRS every 100

milliseconds while “Ignition 1” voltage is in the normal

operating voltage range at the SDM.

Data Link Connector (DLC)

Formerly “DLC” a connector which allows communication

with an external computer, such as a scan tool.

Datum Line

A base line parallel to the plane of the underbody or frame

from which all vertical measurements originate.

Deploy

To inflate the air bag.

Deployment Loops

The circuits which supply current to the air bag

assemblies to deploy the air bag.

Diagnostic Trouble Code (DTC)

Formerly “Code”, a numerical designator used by the

SDM to indicate specific SRS malfunctions.

Driver Current Source

An output of the SDM which applies current into the driver

air bag assembly circuit during the “Initiator Assembly

Resistance Test”.

Driver Air Bag Assembly

An assembly located in the steering wheel hub consisting

of an inflatable bag, an inflator and an initiator.

EEPROM

Electrically Erasable Programmable Read Only Memory.

Memory which retains its contents when power is

removed from the SDM.

Ignition Cycle

The voltage at the SDM “Ignition 1” inputs, with ignition

switch “ON”, is within the normal operating voltage range

for at least ten seconds before turning ignition switch

“OFF”.

Ignition 1

A battery voltage (B+) circuit which is only powered with

the ignition switch in the ON, or START positions.

Initiator

The electrical component inside the air bag assembly

which, when sufficient current flows, sets off the chemical

reaction that inflates the air bag.

“Initiator Assembly Resistance Test”

Tests performed once each ignition cycle when no

malfunctions are detected during “Turn–ON” or

“Continuous Monitoring”. This test checks for the correct

SDM configuration for the vehicle, shorts to “Ignition 1” in