Isuzu engine 4j series. Manual - part 67

6C - 12 ENGINE FUEL

•

Install retaining nut and tighten nut to the specified

torque.

N∙m (Kg∙m/lb∙ft)

39 (4.0/32)

ADJUSTMENT OF INJECTION OPENING

PRESSURE (4JG2 Engine)

•

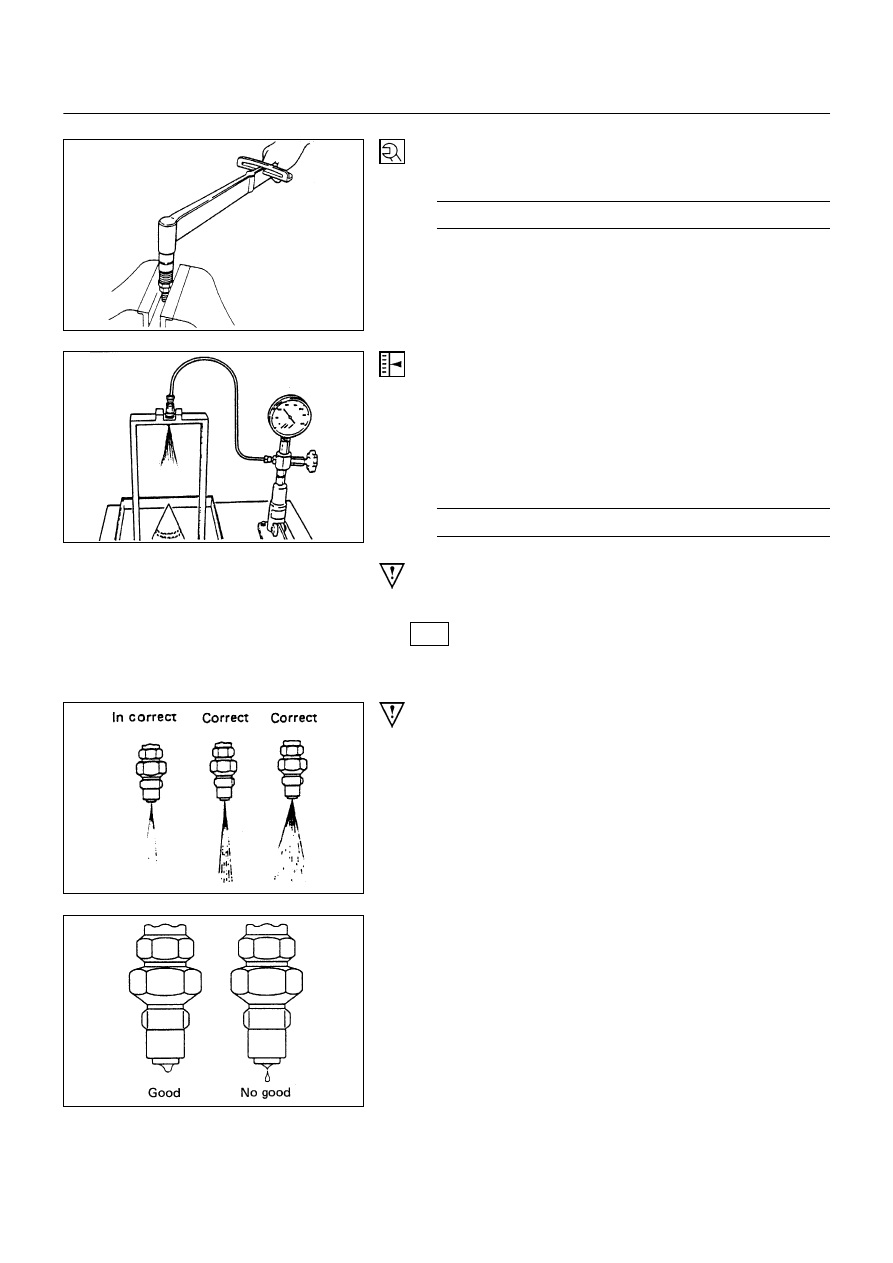

Set nozzle holder assembly on a nozzle tester.

•

Apply hydraulic pressure by operating tester handle,

and make sure fuel cam be injected under the

following pressure.

Kpa (Kg/cm

2

/psi)

14,710 (150/2,133)

CAUTION

•

If not injected under the specified pressure, adjust with

adjusting shim.

Ref.

Types are available in the 1.0 mm - 1.75 mm

thickness range (on a 0.01 mm basis).

•

Unless extremely deformed spray in seen, there is no

problem.

CAUTION

•

The spray condition, when judged with a nozzle tester,

is deemed as normal so long as the spray form is not

excessively deformed.

Oil tight test (4JG2 Engine)

1) After completion of the adjustment of injection

pressure, wipe off light oil at the tip of the nozzle with

waste.

2) With pressure 1,961 Kpa (20 kg/cm

2

/284 psi) less than

the specified injection pressure applied, check to see if

an oil drop trickles off the tip of the nozzle within 10

seconds after application of pressure. (There is no

problem with the nozzle when oil gathers at the tip, but

does not drop off.)

3) When an oil drop trickles, clean the nozzle thoroughly.

Then reassemble it to check for any dropping of oil.

When oil still drops, change it with a new one.

6C-11-1.tif

6C-11-2.tif

6C-11-3.tif

6C-11-4.tif