Infiniti QX56 (JA60). Manual - part 683

ENGINE MAINTENANCE

MA-25

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

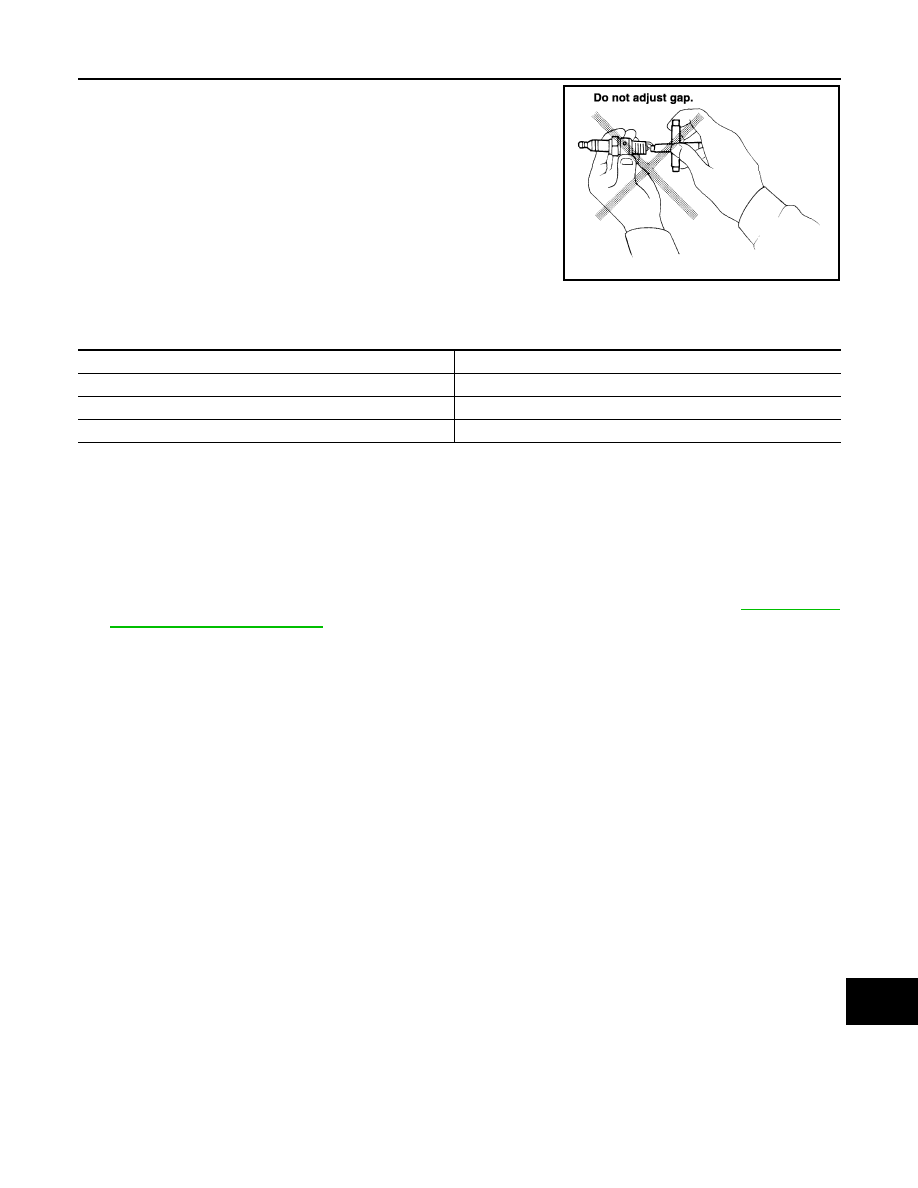

• Checking and adjusting plug gap is not required between change

intervals.

INSTALLATION

Installation is in the reverse order of removal.

Spark Plug Types

CAUTION:

Do not drop or shock spark plug.

EVAP VAPOR LINES

EVAP VAPOR LINES : Checking EVAP Vapor Line

INFOID:0000000005259660

1. Visually inspect the EVAP vapor lines for improper attachment, cracks, damage, loose connections, chaf-

ing, or deterioration.

2. Inspect the vacuum relief valve of the fuel tank filler cap for clogging and sticking. Refer to

SMA806CA

Make

NGK

Model

Standard model

Standard type

DILFR5A-11

Gap (Nominal)

1.1 mm (0.043 in)