Infiniti QX56 (JA60). Manual - part 556

20

10

QUICK REFERENCE CHART: QX56

Wheelarch Height (Unladen*

1

)

INFOID:0000000001842583

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Brake Specification

rakeINFOID:0000000001842585

Unit: mm (in)

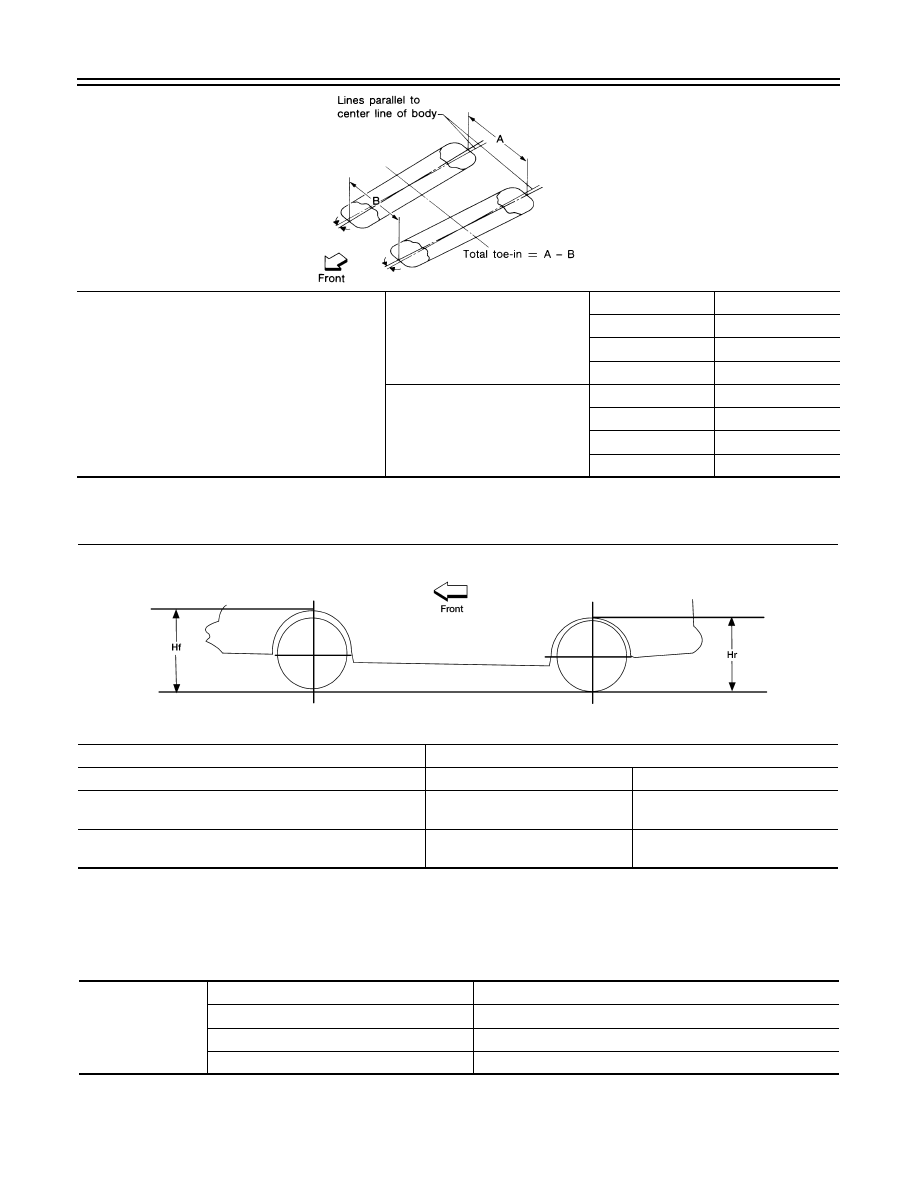

Toe-in

Distance (A - B)

Minimum

0 mm (0 in)

Nominal

3.3 mm (0.130 in)

Maximum

6.6 mm (0.260 in)

Cross toe

2 mm (0.079 in)

Angle (left, right)

Degree minute (decimal degree)

Minimum

0

° 0′ (0°)

Nominal

0

° 7′ (0.11°)

Maximum

0

° 14′ (0.22°)

Cross toe

0

° 8′ (0.14°)

SFA234AC

Suspension type

Air leveling

Applied model

2WD

4WD

Front wheelarch height (Hf)

914

(35.98)

931

(36.65)

Rear wheelarch height (Hr)

911

(35.87)

931

(36.65)

LEIA0085E

Front brake

Brake model

CLZ31VC

Rotor outer diameter

× thickness

350

× 30 (13.80 × 1.2)

Pad Length

× width × thickness

111.0

× 73.5 × 11.88 (4.73 × 2.894 × 0.374)

Cylinder bore diameter (each)

51 (2.01)