Infiniti QX56 (JA60). Manual - part 483

EM-86

< DISASSEMBLY AND ASSEMBLY >

ENGINE UNIT

ASSEMBLY

1. Fully air-blow the coolant and oil passages in the cylinder block, cylinder bore, and crankcase to remove

any foreign material.

WARNING:

Use goggles to protect your eyes.

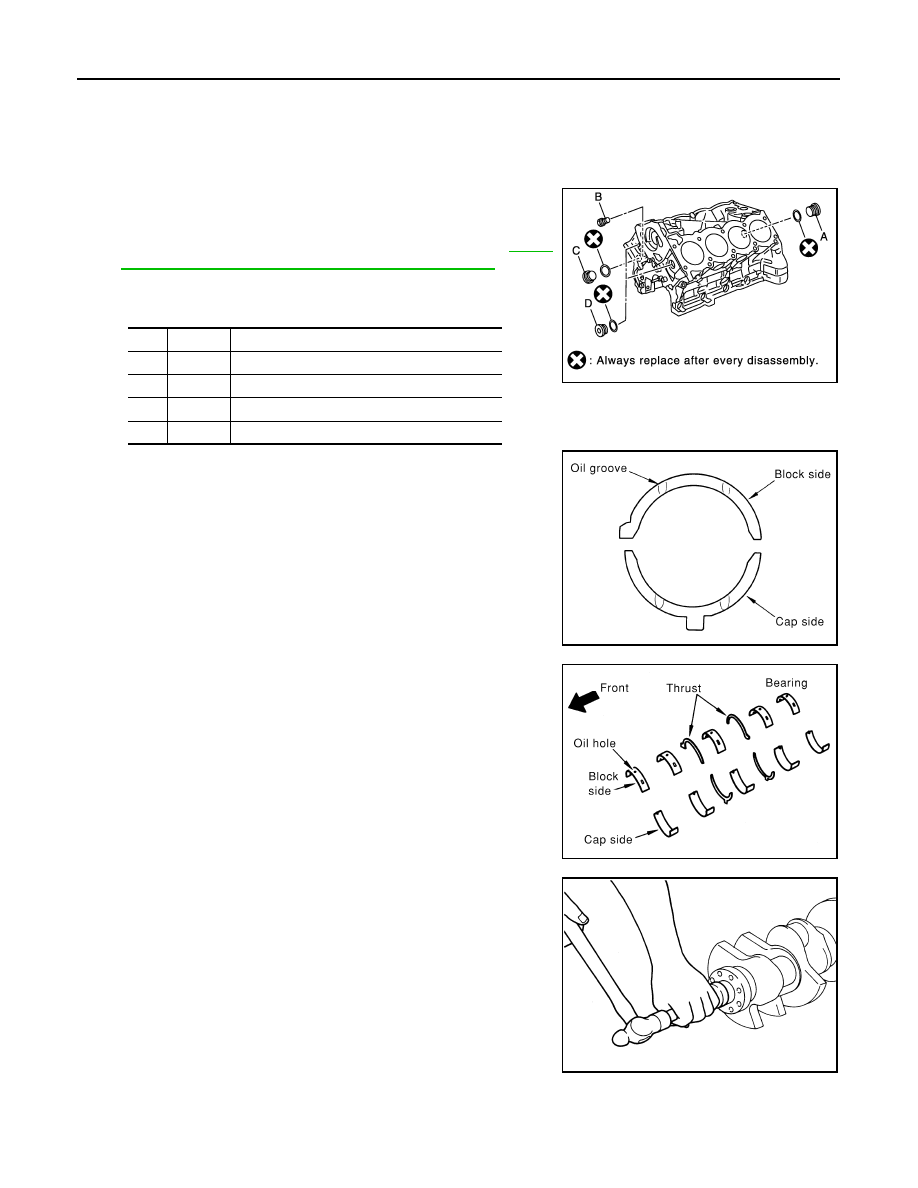

2. Install each plug to the cylinder block (only screw-type plugs are

shown).

• Apply liquid gasket.

Use Genuine Thread Sealant or equivalent. Refer to

"Recommended Chemical Products and Sealants"

.

• Replace copper washers with new ones.

• Tighten each plug as specified below.

3. Install main bearings and thrust bearings.

a. Remove any dust, dirt, and oil on the bearing mating surfaces of

the cylinder block and main bearing caps.

b. Install thrust bearings to both sides of the No. 3 journal housing

on the cylinder block and main bearing caps

• Install thrust bearings with the oil groove facing the crankshaft

arm (outside).

• Install thrust bearings with a protrusion in the center on the

main bearing caps.

c.

Install main bearings paying attention to the direction.

• Install the one with oil holes onto the cylinder block and the

one without oil holes onto the main bearing cap.

• Before installing bearings, apply engine oil to bearing surface

(inside). Do not apply oil to the back surface, but thoroughly

clean it.

• When installing, align the bearing stopper to the notch.

• Ensure the oil holes on the cylinder block and those on the

corresponding bearing are aligned.

4. Install pilot converter to the crankshaft using suitable tool.

5. Install crankshaft to the cylinder block.

• While turning crankshaft by hand, make sure it turns smoothly.

Part

Washer

Tightening torque

A

Yes

53.9 N·m (5.5 kg-m, 40 ft-lb)

B

No

19.6 N·m (2.0 kg-m, 15 ft-lb)

C

Yes

62.7 N·m (6.4 kg-m, 46 ft-lb)

D

Yes

62.7 N·m (6.4 kg-m, 46 ft-lb)

WBIA0419E

PBIC0093E

PBIC0094E

EMP0569D