Infiniti QX56 (JA60). Manual - part 340

EC-12

< BASIC INSPECTION >

[VK56DE]

DIAGNOSIS AND REPAIR WORKFLOW

There are many operating conditions that lead to the malfunction of

engine components. A good grasp of such conditions can make trou-

bleshooting faster and more accurate.

In general, each customer feels differently about a incident. It is

important to fully understand the symptoms or conditions for a cus-

tomer complaint.

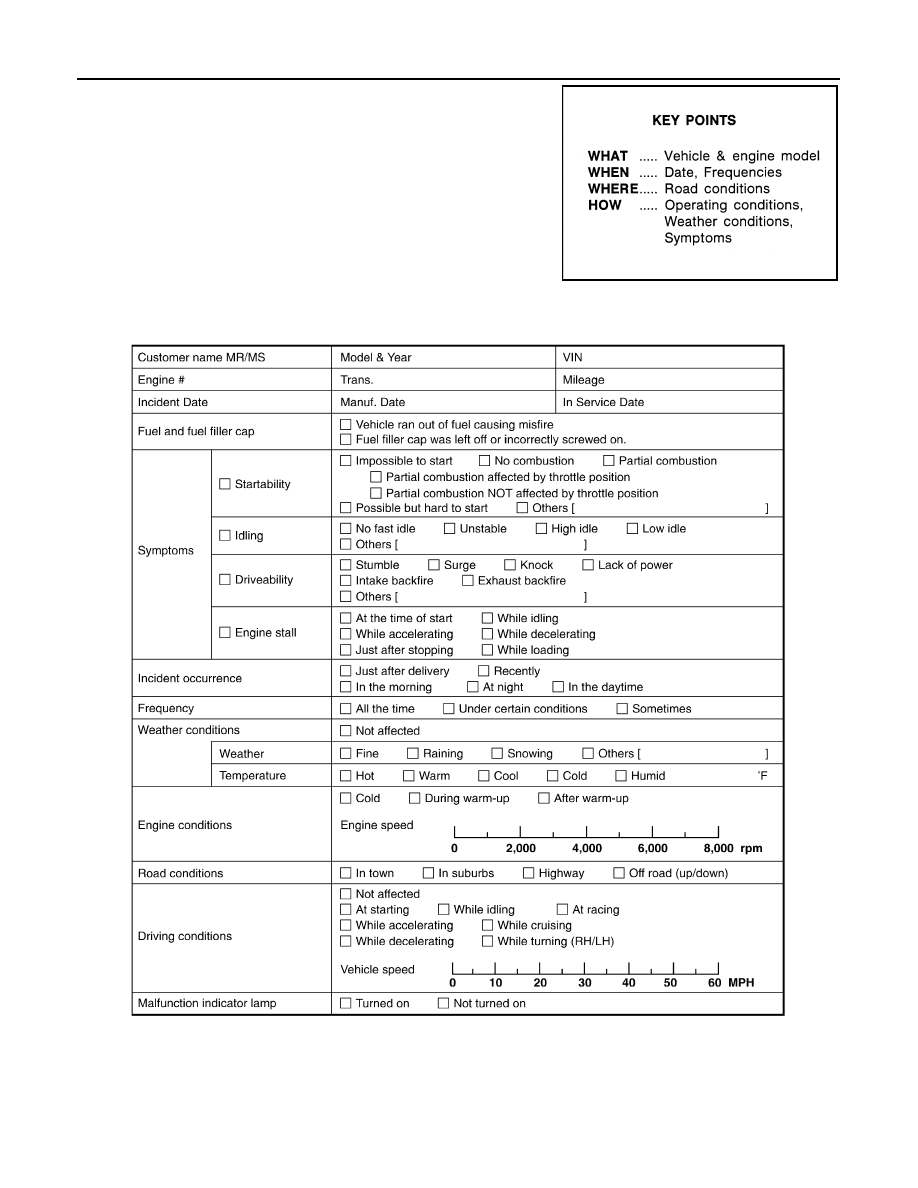

Utilize a diagnostic worksheet like the one on the next page in order

to organize all the information for troubleshooting.

Some conditions may cause the MIL to come on steady or blink and

DTC to be detected. Examples:

• Vehicle ran out of fuel, which caused the engine to misfire.

• Fuel filler cap was left off or incorrectly screwed on, allowing fuel to

evaporate into the atmosphere.

Worksheet Sample

SEF907L

MTBL0017