Infiniti QX56 (Z62). Manual - part 661

EM-84

< REMOVAL AND INSTALLATION >

CAMSHAFT

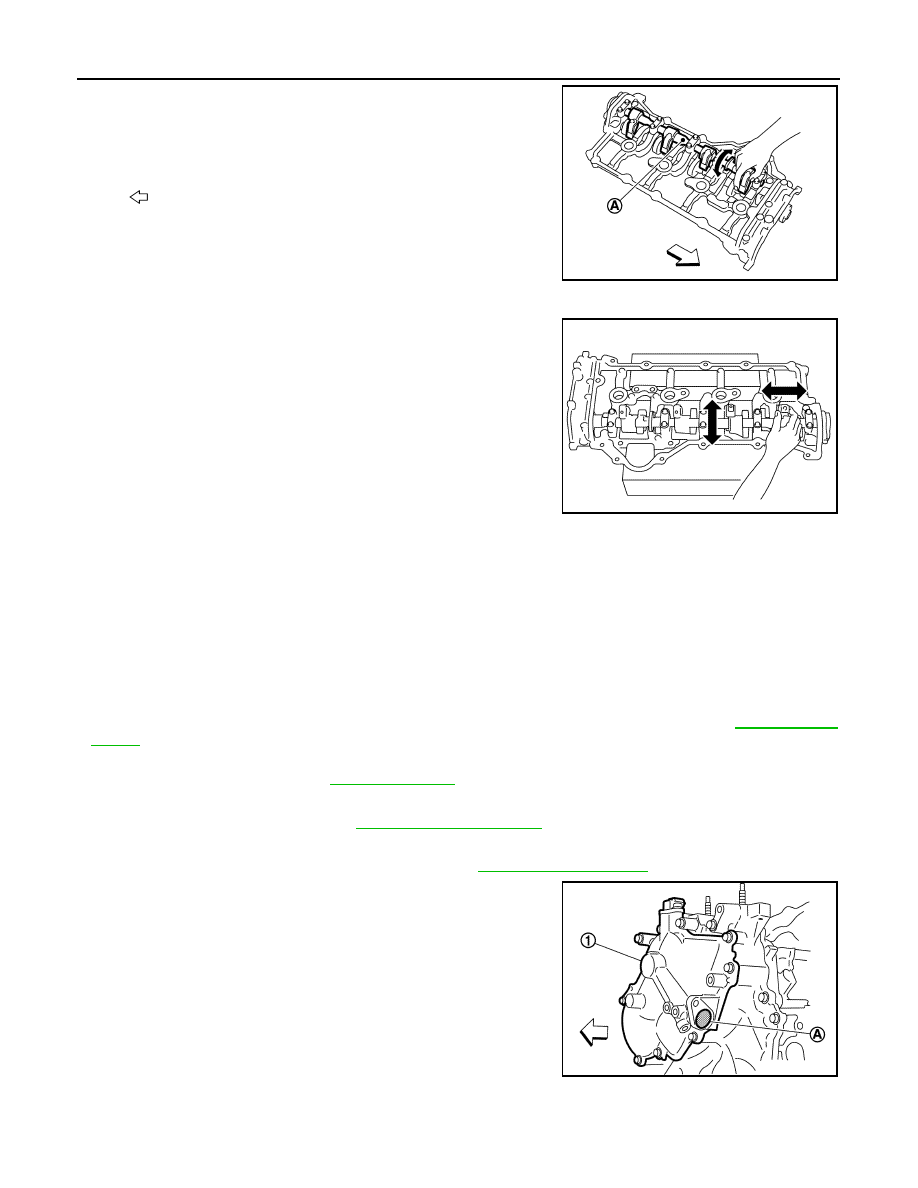

• Move control shaft (A) to the small stopper and large stopper to

check that the control shaft functions smoothly.

CAUTION:

Turn VVEL ladder assembly upside down to prevent the drive

shaft from dropping off.

RINK CHECK FOR BACK-LASH (BONDING)

• Check that the link and the shaft of drive shaft and control shaft are

not fixed.

• Check this by moving drive shaft and control shaft in the axial and

rotation directions.

• If there is an unusualness related to the above three items, replace VVEL ladder assembly & cylinder head

assembly.

NOTE:

VVEL ladder assembly cannot be replaced as a single part, because it is machined together with cylinder

head assembly.

INSPECTION AFTER ASSEMBLY

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

• Perform this inspection only when DTC P0011, P0021 are detected in self-diagnostic results of CON-

SULT-III and it is directed according to inspection procedure of EC section. Refer to

.

• Check when engine is cold to prevent burns from the splashing engine oil.

1.

Check engine oil level. Refer to

.

2.

Perform the following procedure to prevent the engine from being unintentionally started while checking.

a.

Release the fuel pressure. Refer to

.

b.

Disconnect ignition coil and injector harness connectors.

3.

Remove valve timing control solenoid valve. Refer to

4.

Crank engine, and then check that engine oil comes out from

valve timing control solenoid valve hole (A). End crank after

checking.

WARNING:

Be careful not to touch rotating parts (drive belt, idler pul-

ley, and crankshaft pulley, etc.).

CAUTION:

• Prevent splashing by using a shop cloth to prevent the

worker from injury from engine oil and to prevent engine

oil contamination.

• Prevent splashing by using a shop cloth to prevent engine oil from being splashed to engine and

vehicle. Especially, be careful not to apply engine oil to rubber parts of drive belt, engine mount-

ing insulator, etc. Wipe engine oil out immediately if it is splashed.

: Engine front

JPBIA3521ZZ

JPBIA3522ZZ

1

: Valve timing control cover (bank 2)

JPBIA3523ZZ