Infiniti QX56 (Z62). Manual - part 554

EC-194

< DTC/CIRCUIT DIAGNOSIS >

[VK56VD]

P0075, P0081 IVT CONTROL SOLENOID VALVE

2.

Disconnect ECM harness connector.

3.

Check the continuity between IVT control solenoid valve harness connector and ECM harness connector.

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair open circuit, short to ground or short to power in harness or connectors.

4.

CHECK IVT CONTROL SOLENOID VALVE

EC-194, "Component Inspection (Intake Valve Timing Control Solenoid Valve)"

.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Replace malfunctioning IVT control solenoid valve. Refer to

.

5.

CHECK INTERMITTENT INCIDENT

GI-40, "Intermittent Incident"

>> INSPECTION END

Component Inspection (Intake Valve Timing Control Solenoid Valve)

INFOID:0000000006288359

1.

CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE-I

1.

Turn ignition switch OFF.

2.

Disconnect intake valve timing control solenoid valve harness connector.

3.

Check resistance between intake valve timing control solenoid valve terminals as per the following.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Replace malfunctioning intake valve timing control solenoid valve. Refer to

2.

CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE-II

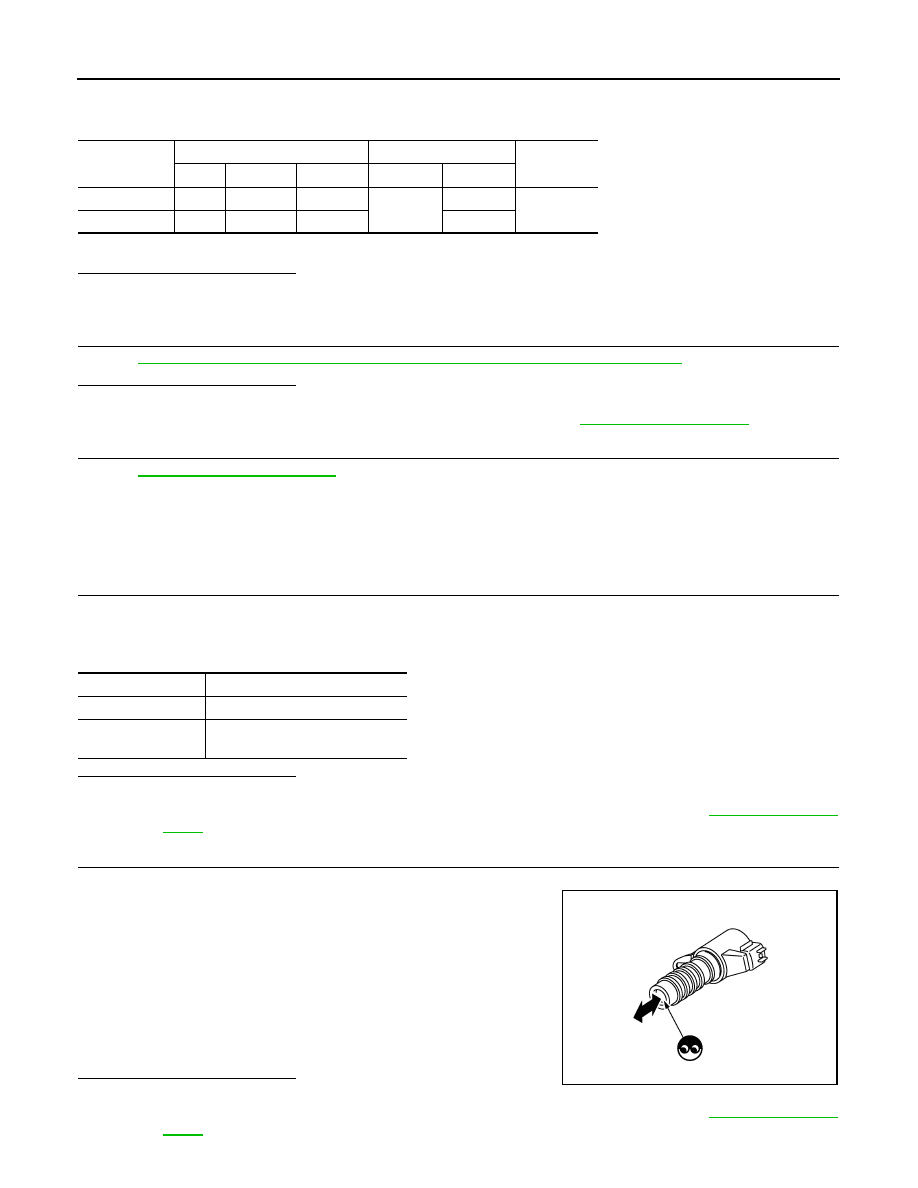

1.

Remove intake valve timing control solenoid valve.

2.

Provide 12 V DC between intake valve timing control solenoid

valve terminals 1 and 2, and then interrupt it. Check that the

plunger moves as shown in the figure.

CAUTION:

Never apply 12 V DC continuously for 5 seconds or more.

Doing so may result in damage to the coil in intake valve

timing control solenoid valve.

NOTE:

Always replace O-ring when intake valve timing control

solenoid valve is removed.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace malfunctioning intake valve timing control solenoid valve. Refer to

DTC

IVT control solenoid valve

ECM

Continuity

Bank

Connector

Terminal

Connector

Terminal

P0075

1

F47

1

F111

49

Existed

P0081

2

F61

1

54

Terminals

Resistance

1 and 2

7.0 - 7.7

Ω

[at 20

°

C (68

°

F)]

1 or 2 and ground

∞

Ω

(Continuity should not exist)

JMBIA0079ZZ