Infiniti Q45. Manual - part 476

DTC P1225 TP SENSOR

EC-543

C

D

E

F

G

H

I

J

K

L

M

A

EC

Diagnostic Procedure

NBS00229

1.

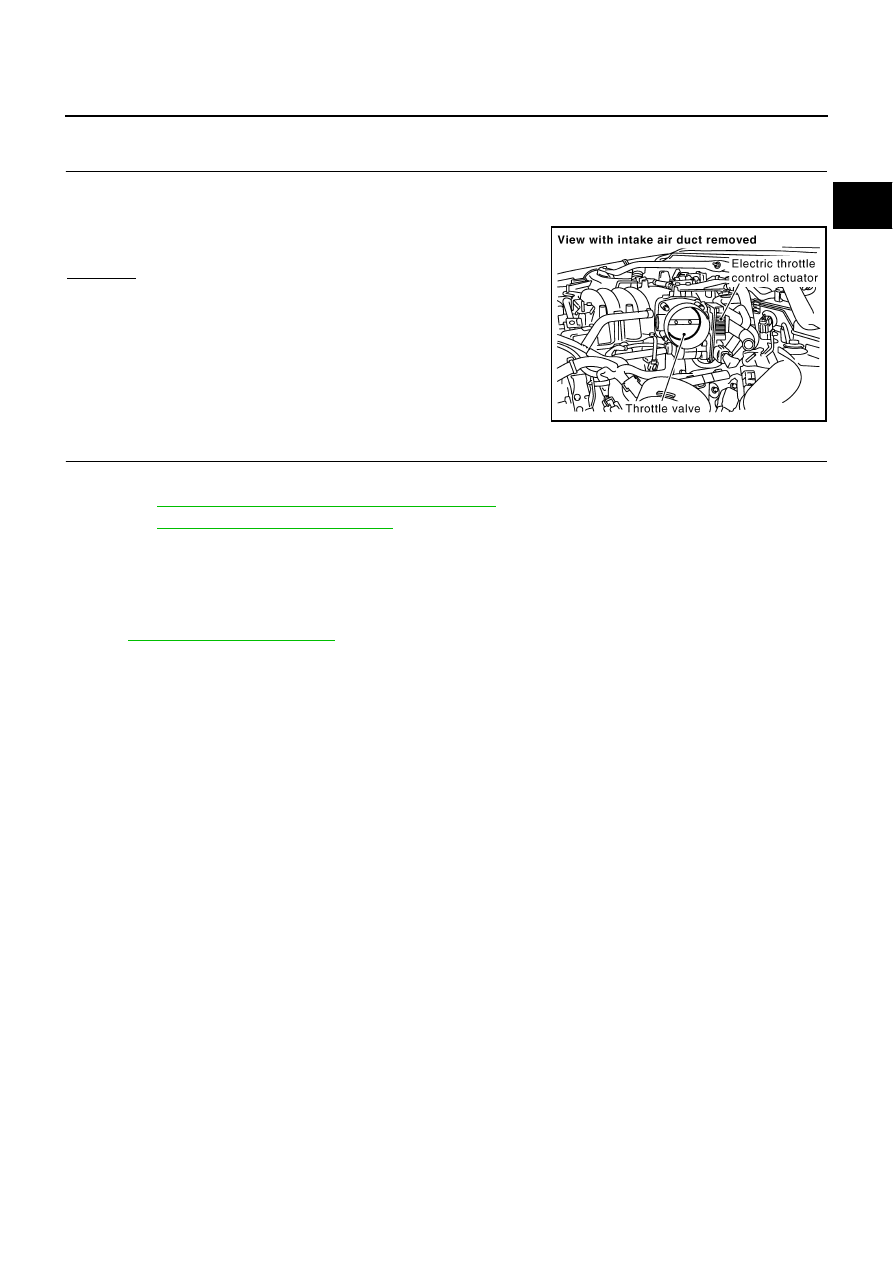

CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY

1.

Turn ignition switch OFF.

2.

Remove the intake air duct.

3.

Check if foreign matter is caught between the throttle valve and

the housing.

OK or NG

OK

>> GO TO 2.

NG

>> Remove the foreign matter and clean the electric throttle

control actuator inside.

2.

REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1.

Replace the electric throttle control actuator.

2.

Perform

EC-78, "Throttle Valve Closed Position Learning"

3.

Perform

EC-78, "Idle Air Volume Learning"

>> INSPECTION END

Removal and Installation

NBS0022A

ELECTRIC THROTTLE CONTROL ACTUATOR

Refer to

PBIB2439E