Infiniti Q45. Manual - part 475

DTC P1220 FUEL PUMP CONTROL MODULE (FPCM)

EC-539

C

D

E

F

G

H

I

J

K

L

M

A

EC

5.

CHECK FPCM GROUND CIRCUIT-II FOR OPEN AND SHORT

1.

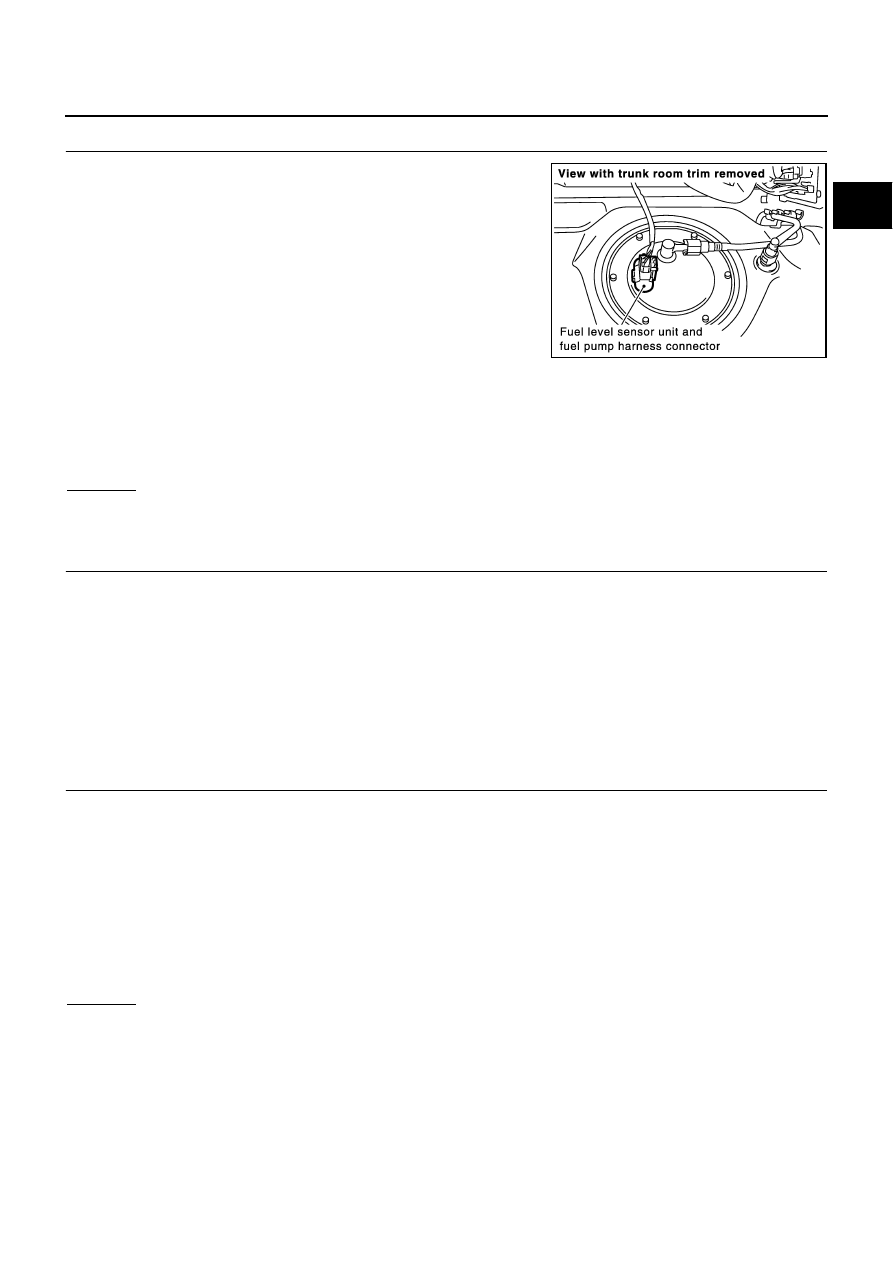

Disconnect “fuel level sensor unit and fuel pump” harness con-

nector.

2.

Disconnect dropping resistor harness connector.

3.

Check harness continuity between the following;

“fuel level sensor unit and fuel pump” terminal 1 and dropping

resistor terminal 2,

FPCM terminal 4 and dropping resister terminal 2.

Refer to Wiring Diagram.

4.

Check harness continuity between the following;

FPCM terminal 4 and ground,

“fuel level sensor and fuel pump” terminal 1 and ground.

Refer to Wiring Diagram.

5.

Also check harness for short to power.

OK or NG

OK

>> GO TO 7.

NG

>> GO TO 6.

6.

DETECT MALFUNCTIONING PART

Check the following.

●

Harness connectors B63, B263

●

Harness for open or short between “fuel level sensor unit and fuel pump” and dropping resistor

●

Harness for open or short between FPCM and dropping resistor

●

Harness for open or short between “fuel level sensor unit and fuel pump” and ground

●

Harness for open or short between FPCM and ground

>> Repair open circuit or short to ground or short to power in harness or connectors.

7.

CHECK FPCM INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Disconnect ECM harness connector.

2.

Check harness continuity between ECM terminal 38 and FPCM terminal 4.

Refer to Wiring Diagram.

3.

Check harness continuity between ECM terminal 38 and ground.

Refer to Wiring Diagram.

4.

Also check harness for short to power.

OK or NG

OK

>> GO TO 9.

NG

>> GO TO 8.

Continuity should exist.

Continuity should not exist.

PBIB1249E

Continuity should exist.

Continuity should not exist.