Infiniti Q45. Manual - part 281

RADIATOR (ALUMINUM TYPE)

CO-17

C

D

E

F

G

H

I

J

K

L

M

A

CO

4.

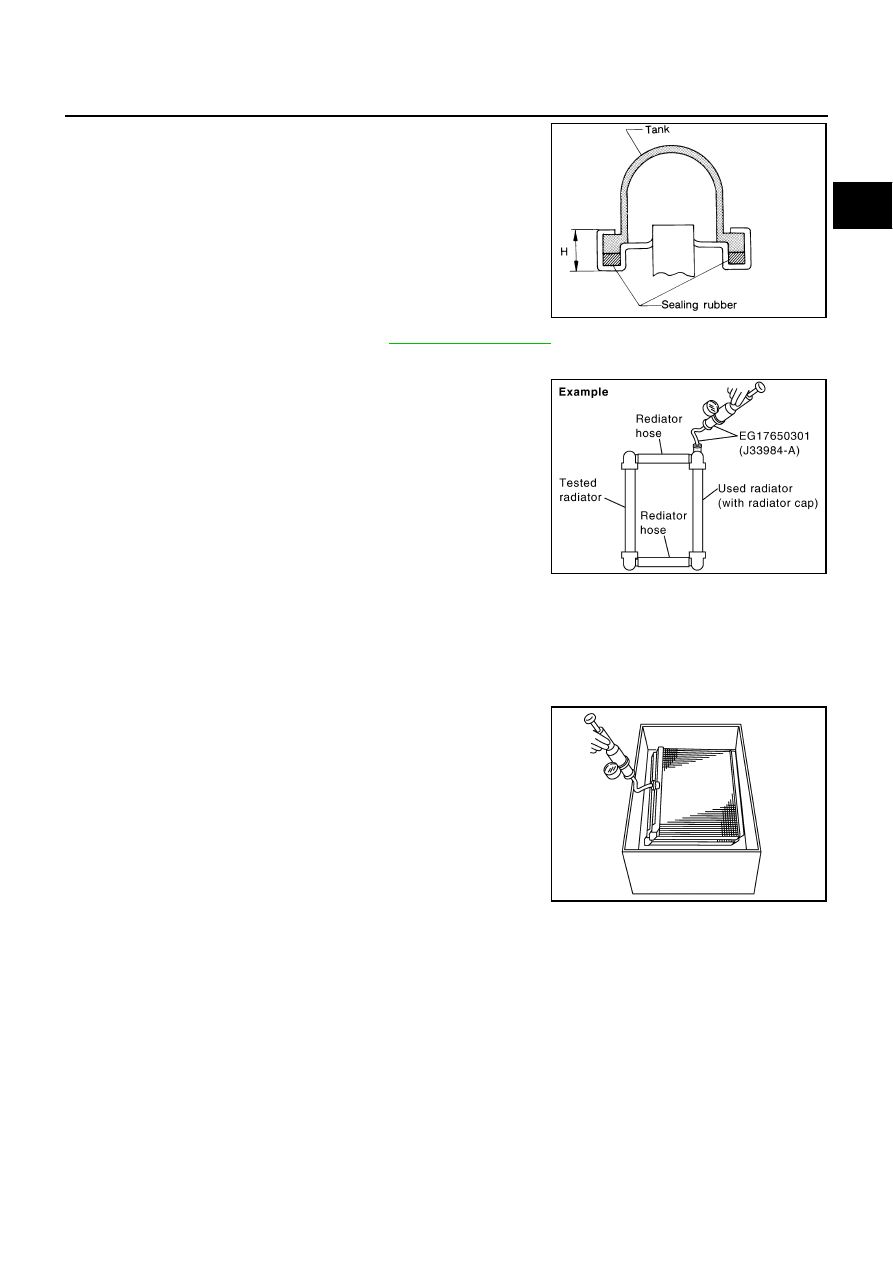

Make sure that the rim is completely crimped down.

5.

Confirm that there is no leakage. Refer to

INSPECTION

1.

Apply pressure with the radiator cap tester adapter (SST) and

the radiator cap tester (commercial service tool).

●

Provide used radiator and connect it to tested radiator using

radiator hoses as shown in the figure.

NOTE:

The used radiator should be tested beforehand to confirm it

has no leakage. If used one is not available, it is possible to

use new service part as a radiator testing tool.

WARNING:

To prevent the risk of the hose coming undone while under pressure, securely fasten it down with

a hose clamp.

CAUTION:

Attach a hose to A/T fluid cooler to seal its inlet and outlet.

2.

Check for leakage by soaking radiator in the water container

with the testing pressure applied.

Standard height “H”

: 8.0 - 8.4 mm (0.315 - 0.331 in)

SLC554A

Testing pressure

: 157 kPa (1.6 kg/cm

2

, 23 psi)

PBIC1658E

PBIC1699E