Infiniti Q45 (FY33). Manual - part 98

SBR043EA

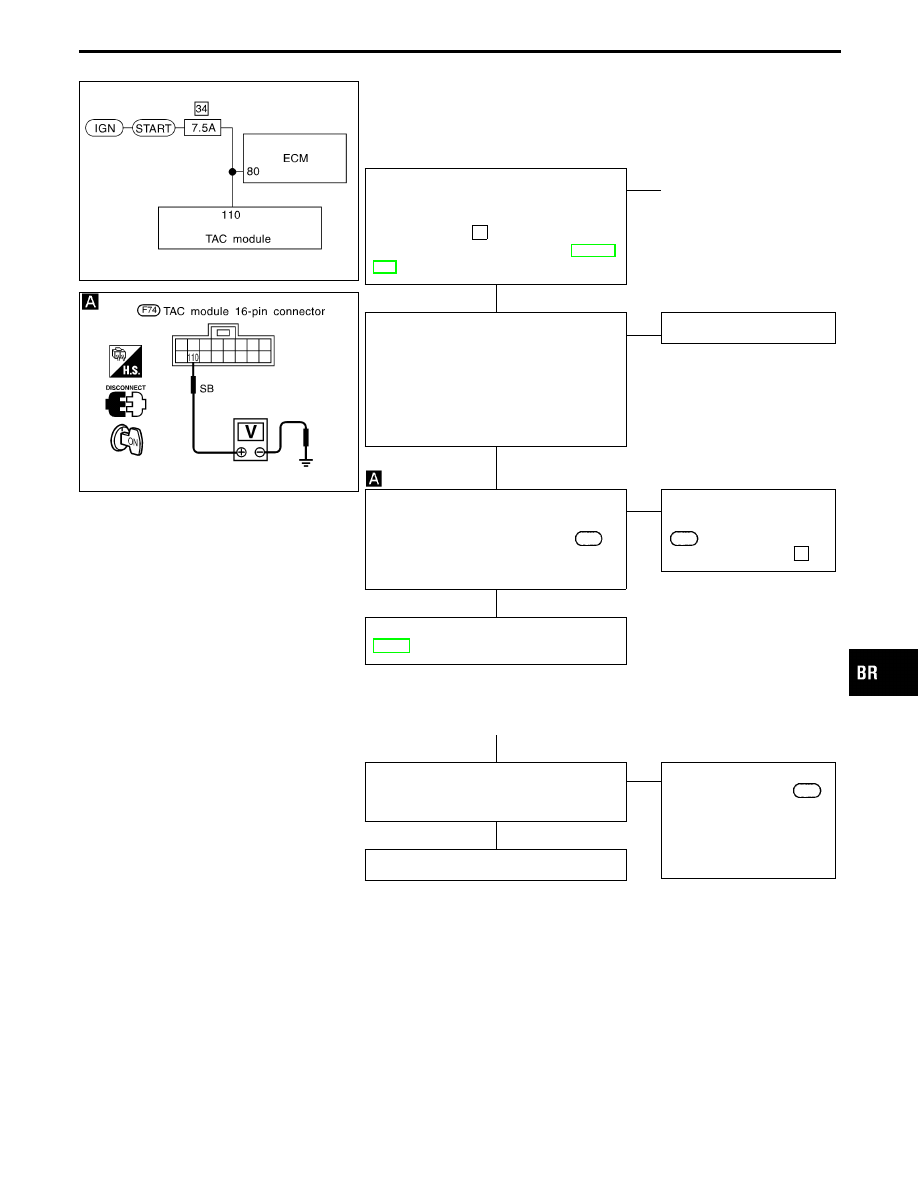

Diagnostic Procedure 21 (ENGINE START SIG:

Start signal circuit)

Code No. 31 of TAC module

SBR600CD

START SIGNAL POWER SUPPLY

CHECK

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check 7.5A fuse

34

. For fuse layout, refer

to POWER SUPPLY ROUTING in EL sec-

tion.

OK

E

NG

q

A

(See below.)

1. Disconnect connectors from TAC mod-

ule. Check terminals for damage or

loose connection. Then reconnect con-

nectors.

2. Carry out self-diagnosis again.

Do SLIP indicator and TCS OFF indi-

cator activate again?

Yes

E

No

Inspection end

I

Reconnect ECM connector.

I

Turn ignition switch ON.

I

Check voltage between terminal

110

for TAC module connector and ground.

Voltage: Approx. 12V

OK

E

NG

Repair harness and con-

nectors between terminal

110

for TAC module con-

nector and 7.5A fuse

34

.

Preliminary check (Basic inspection 3),

BR-48

q

A

Replace fuse.

Does the fuse blow out when ignition

switch is turned “START”?

No

E

Yes

Check the following.

I

Harness connector

F74

I

Harness for open or

short between TAC mod-

ule connector and fuse

If NG, repair harness or

connectors.

Inspection end

GI

MA

EM

LC

EC

FE

AT

PD

FA

RA

ST

RS

BT

HA

EL

IDX

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

H

H

H

H

H

BR-109