Infiniti M45 (Y34). Manual - part 69

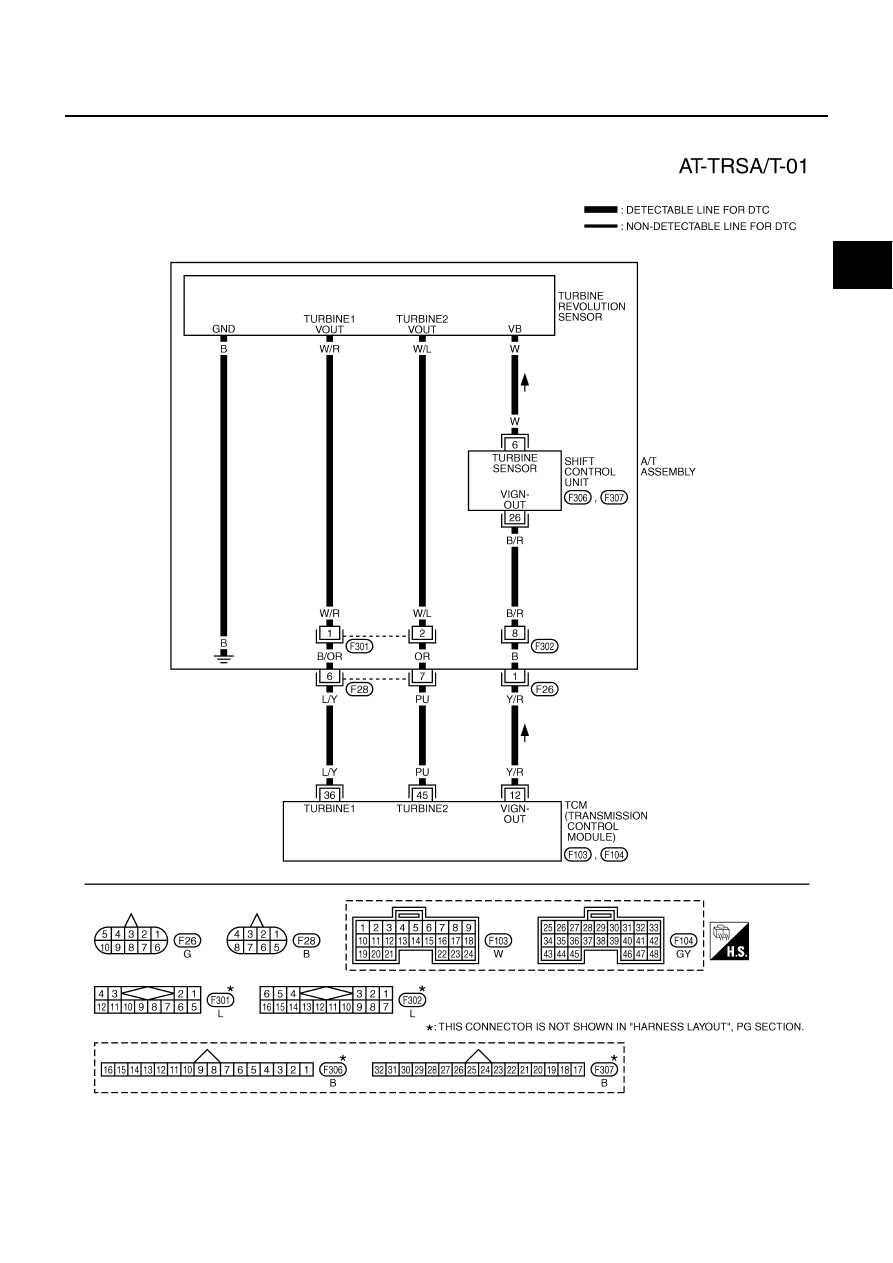

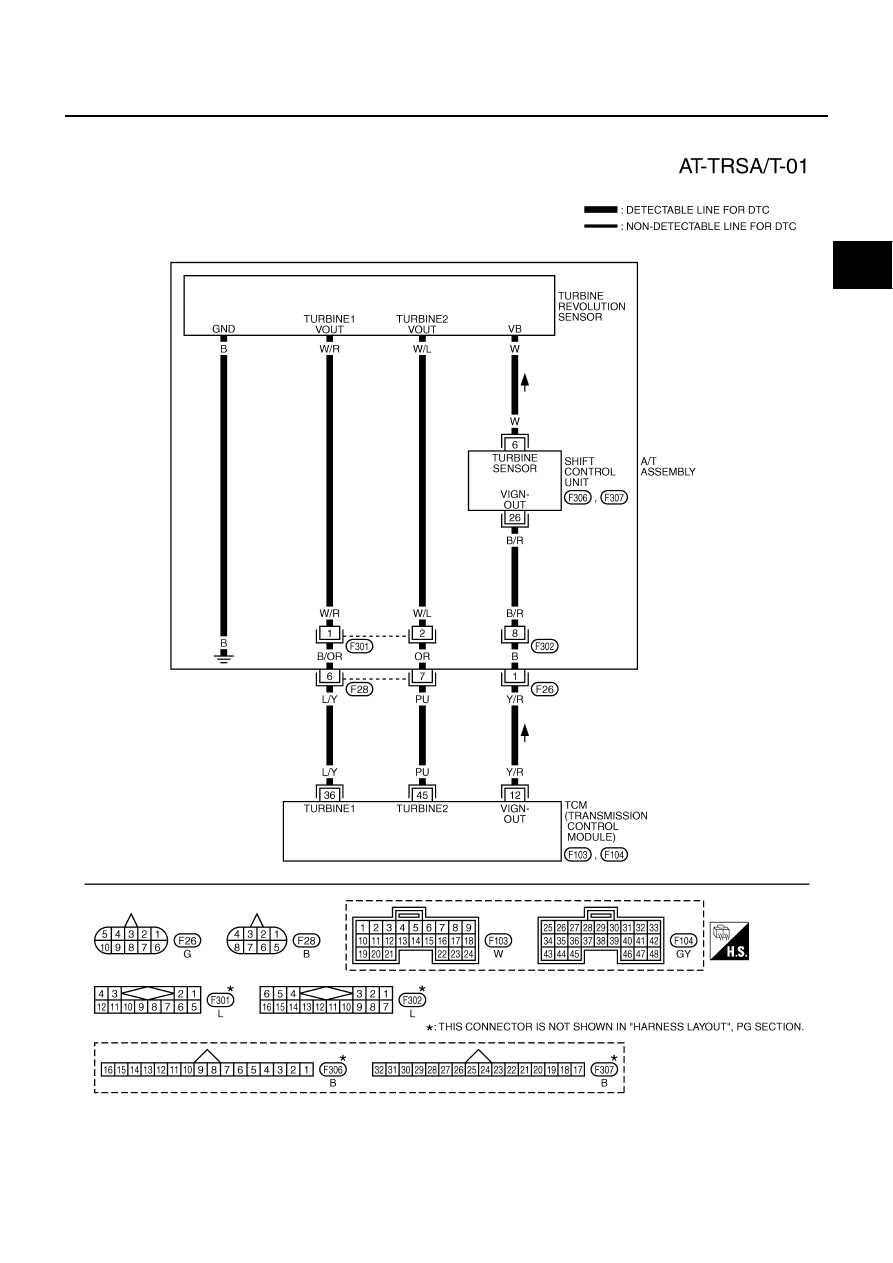

DTC P1716 TURBINE REVOLUTION SENSOR

AT-161

D

E

F

G

H

I

J

K

L

M

A

B

AT

Wiring Diagram — AT — TRSA/T

ACS0048I

TCWA0120E

|

|

|

DTC P1716 TURBINE REVOLUTION SENSOR AT-161 D E F G H I J K L M A B AT Wiring Diagram — AT — TRSA/T ACS0048I TCWA0120E |