Infiniti F50. Manual - part 716

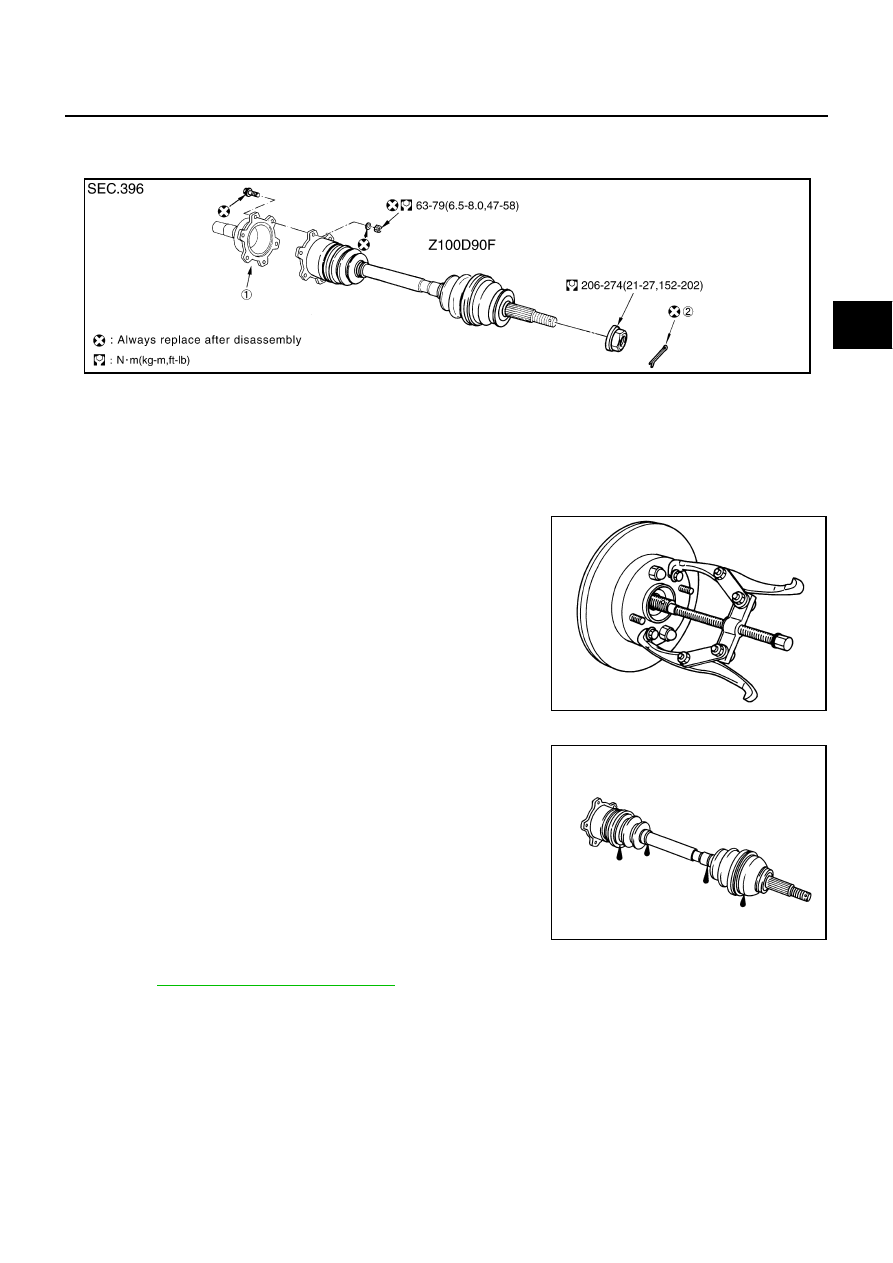

REAR DRIVE SHAFT

RAX-9

C

E

F

G

H

I

J

K

L

M

A

B

RAX

REAR DRIVE SHAFT

PFP:39600

Removal and Installation

EDS000WQ

REMOVAL

1.

Remove tire with power tool.

2.

Remove cotter pin. Then remove lock nut from drive shaft.

3.

Remove exhaust center tube.

4.

Remove fixing nuts and bolts between final drive and drive shaft.

5.

Using a puller (suitable tool), remove drive shaft from axle.

CAUTION:

When removing drive shaft, do not apply an excessive

angle to drive shaft joint. Also be careful not to excessively

extend slide joint.

INSPECTION AFTER REMOVAL

●

Move joint in the up/down, left/right, and axial direction. Check

for any rough movement or significant looseness.

●

Check boot for cracks or other damage, and also for grease

leakage.

●

If a trouble is found, disassemble drive shaft, and then replace

with new one.

INSTALLATION

●

Refer to

RAX-9, "Removal and Installation"

for tightening torque. Tighten in the reverse order of removal.

CAUTION:

Refer to component parts location and do not reuse non-reusable parts.

1.

Side flange

2.

Cotter pin

SDIA1174E

SDIA0972J

RAA0030D