Infiniti F50. Manual - part 677

ENGINE MAINTENANCE

MA-13

C

D

E

F

G

H

I

J

K

M

A

B

MA

ENGINE MAINTENANCE

PFP:00100

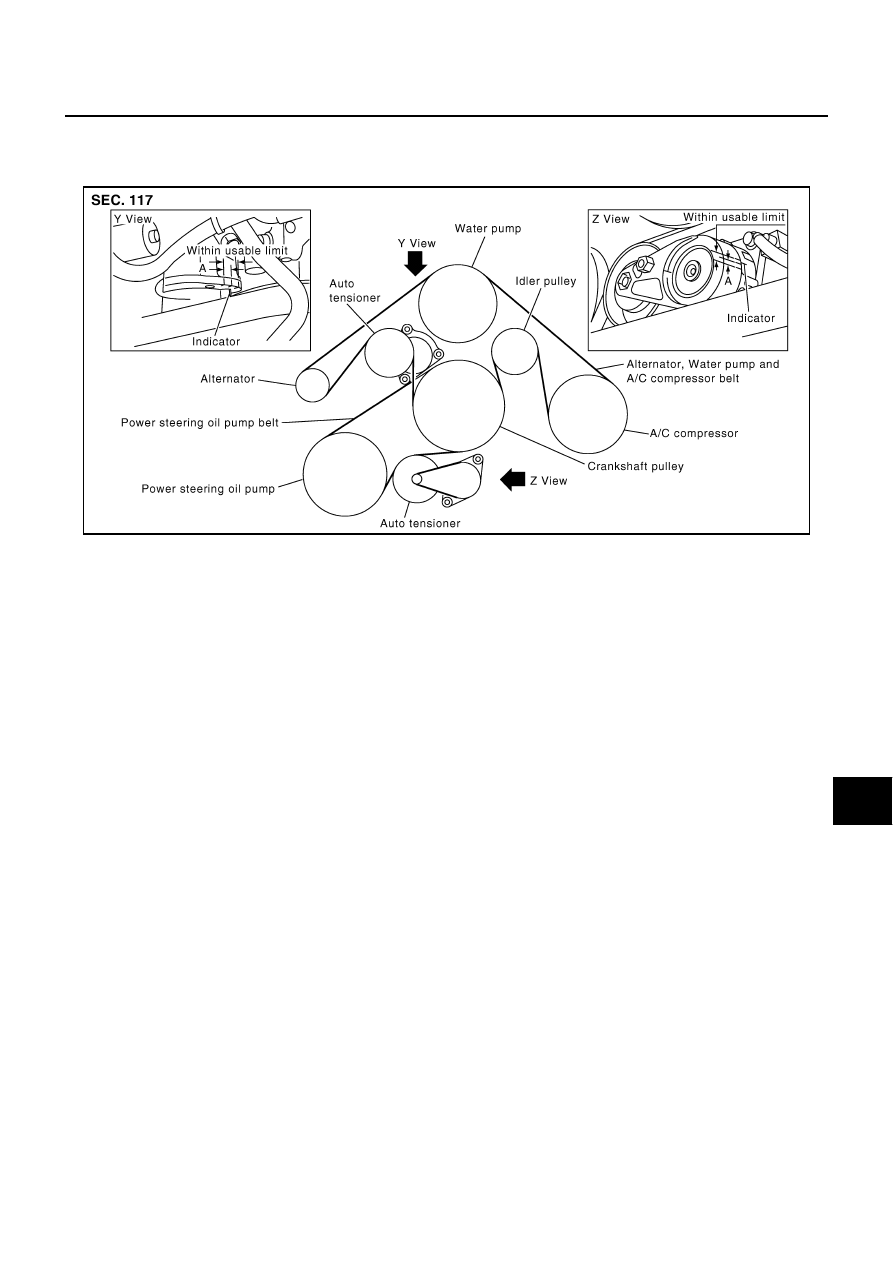

Checking Drive Belts

ELS000KQ

WARNING:

Be sure to perform when the engine is stopped.

●

Remove air duct (inlet) when inspecting drive belt for alternator, water pump and A/C compressor.

●

Remove undercover (with power tool) when inspecting power steering oil pump belt.

●

Make sure that indicator (single line notch) of each auto tensioner is within the allowable working range

(between three line notches).

NOTE:

●

Check the auto tensioner indication when engine is cold.

●

When new drive belt is installed, the range should be A.

●

The indicator notch is located on the moving side of the tensioner for alternator, water pump and A/C

compressor belt, while it is found on the fixed side for power steering oil pump belt.

●

Visually check entire belt for wear, damage or cracks.

●

If the indicator is out of allowable working range or belt is damaged, replace the belt.

Tension Adjustment

ELS000KR

Belt tensioning is not necessary, as it is automatically adjusted by auto tensioner.

Changing Engine Coolant

ELS000KS

WARNING:

●

To avoid being scalded, never change engine coolant when engine is hot.

●

Wrap a thick cloth around cap and carefully remove the cap. First, turn the cap a quarter of a turn

to release built-up pressure. Then turn the cap all the way.

DRAINING ENGINE COOLANT

1.

Remove engine undercover with power tool.

2.

Open radiator drain plug at the bottom of radiator, and remove radiator cap.

●

Be careful not to allow engine coolant to contact drive belts.

When draining all engine coolant in the system, also perform the following steps.

PBIC2162E