Infiniti F50. Manual - part 542

CAMSHAFT

EM-55

C

D

E

F

G

H

I

J

K

L

M

A

EM

9.

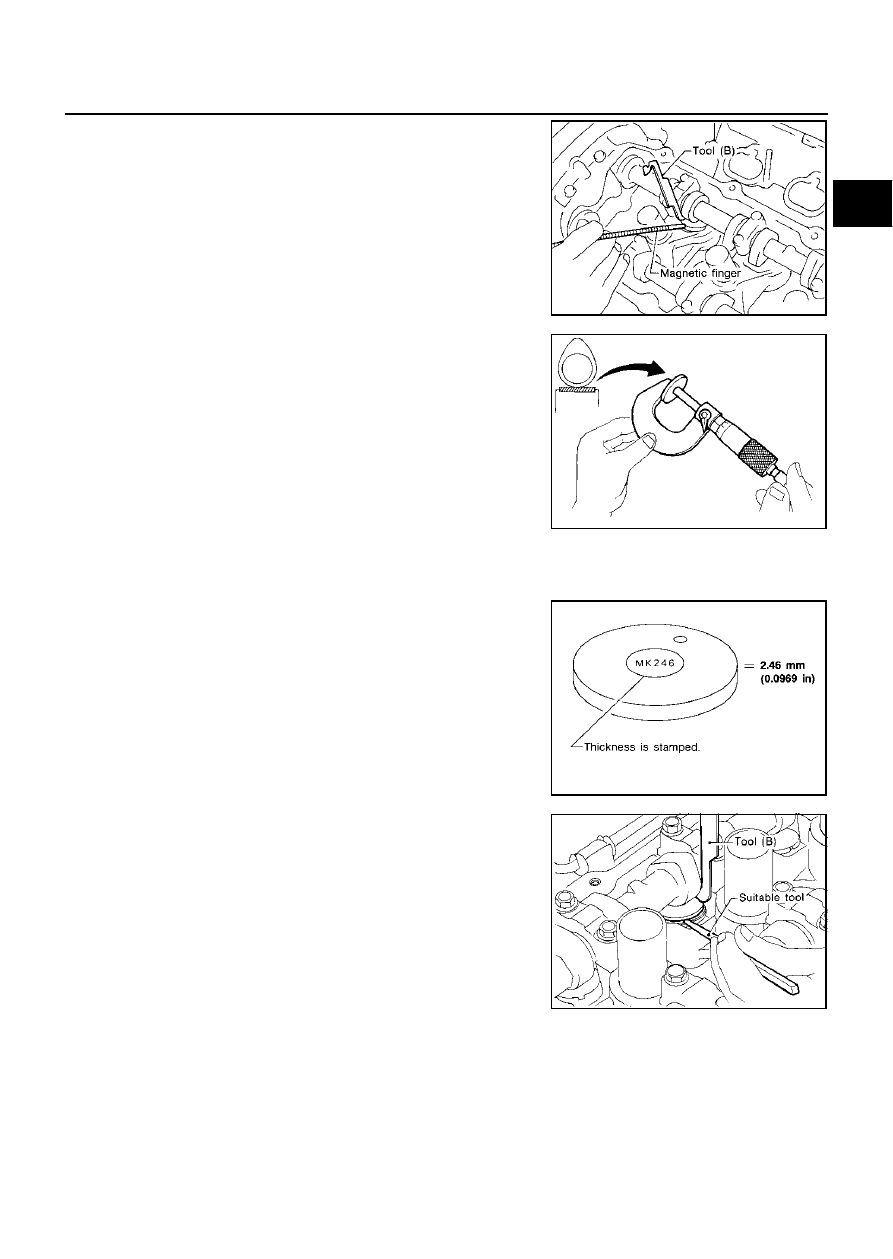

Remove adjusting shim using a small screwdriver and a mag-

netic finger.

10. Determine replacement adjusting shim size following formula.

●

Using a micrometer determine thickness of removed shim

with measured at center.

●

Calculate thickness of new adjusting shim so valve clearance

comes within specified values (Cold value).

R = Thickness of removed shim

N = Thickness of new shim

M = Measured valve clearance

Shims are available in 64 sizes from 2.32 mm (0.0913 in) to 2.95 mm (0.1161 in) in steps of 0.01

mm (0.0004 in).

●

Select new shim with thickness as close as possible to calcu-

lated value.

11. Install new shim using a suitable tool.

●

Install with the surface on which the thickness is

stamped facing down.

SEM872E

Intake

: N = R + [M

−

0.30 mm (0.0118 in)]*

Exhaust

: N = R + [M

−

0.33 mm (0.0130 in)]*

*: Approximately 20

°

C (68

°

F)

SEM145D

SEM873E

SEM146D