Infiniti F50. Manual - part 530

PREPARATION

EM-7

C

D

E

F

G

H

I

J

K

L

M

A

EM

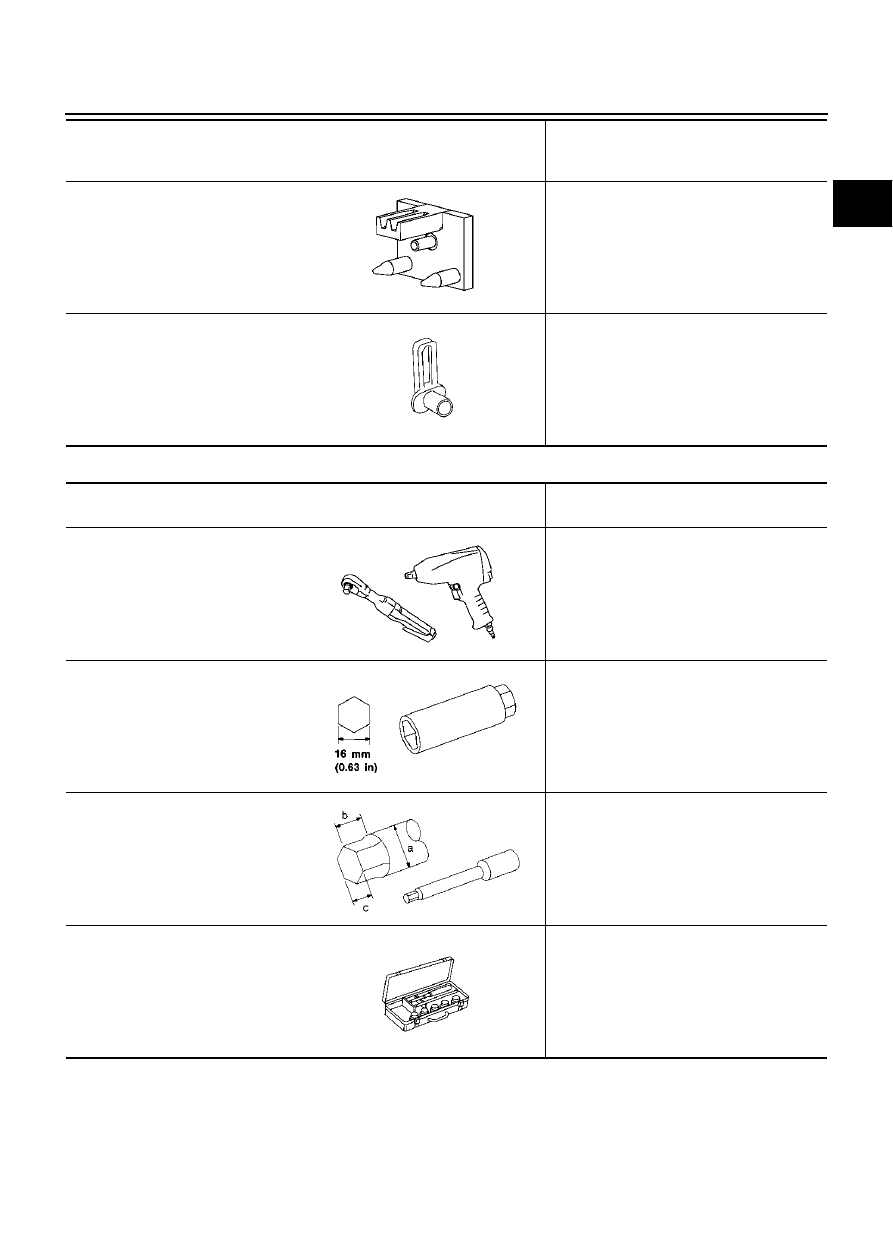

Commercial Service Tools

EBS001L6

—

(J- 45476)

Ring gear stopper

Removing and installing crankshaft pulley

—

(J-45488)

Quick connector release

Removing fuel tube quick connectors in

engine room

(Available in SEC. 164 of PARTS CATALOG:

Part No. 16441 6N210)

Tool number

(Kent-Moore No.)

Tool name

Description

PBIC1655E

PBIC0198E

(Kent-Moore No.)

Tool name

Description

Power tool

Loosening bolts and nuts

Spark plug wrench

Removing and installing spark plug

(J24239-01)

Cylinder head bolt wrench

Loosening and tightening cylinder head bolt,

and used with angle wrench [SST:

KV10112100 (BT8653-A)]

a: 13 (0.51) dia.

b: 12 (0.47)

c: 10 (0.39)

Unit: mm (in)

Valve seat cutter set

Finishing valve seat dimensions

PBIC0190E

S-NT047

NT583

S-NT048