Infiniti F50. Manual - part 455

DTC P1140, P1145 IVT CONTROL POSITION SENSOR

EC-461

C

D

E

F

G

H

I

J

K

L

M

A

EC

7.

CHECK CRANKSHAFT POSITION SENSOR (POS)

Refer to

EC-314, "Component Inspection"

OK or NG

OK

>> GO TO 8.

NG

>> Replace crankshaft position sensor (POS).

8.

CHECK CAMSHAFT POSITION SENSOR (PHASE)

Refer to

EC-319, "Component Inspection"

OK or NG

OK

>> GO TO 9.

NG

>> Replace camshaft position sensor (PHASE).

9.

CHECK CAMSHAFT

Check accumulation of debris to the signal pick-up portion of the camshaft. Refer to

OK or NG

OK

>> GO TO 10.

NG

>> Remove debris and clean the signal pick-up cutout of camshaft.

10.

CHECK INTERMITTENT INCIDENT

Refer to

EC-132, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT"

>> INSPECTION END

Component Inspection

EBS00MIE

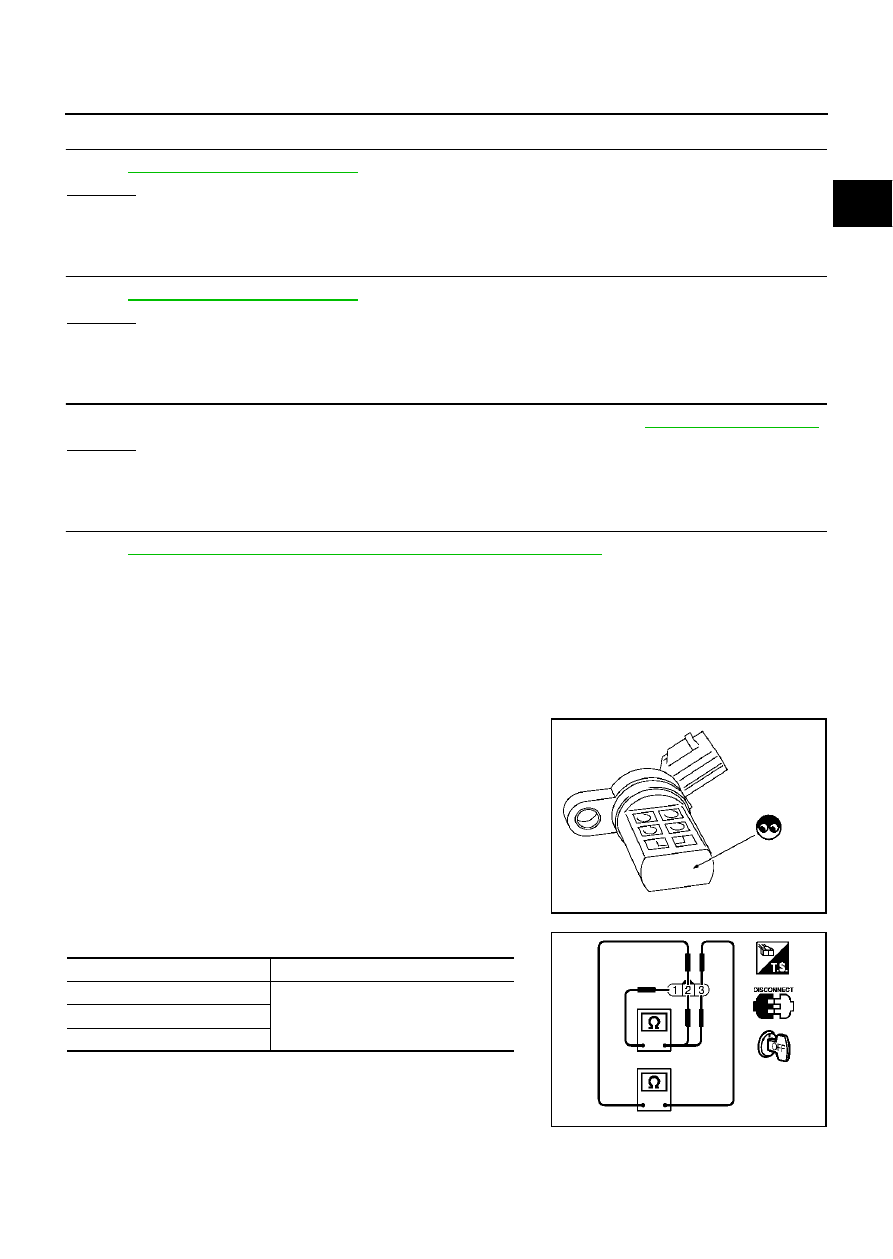

INTAKE VALVE TIMING CONTROL POSITION SENSOR

1.

Disconnect intake valve timing control position sensor harness connector.

2.

Loosen the fixing bolt of the sensor.

3.

Remove the sensor.

4.

Visually check the sensor for chipping.

5.

Check resistance as shown below.

6.

If NG, replace intake valve timing control position sensor.

SEF362Z

Terminal No. (Polarity)

Resistance

Ω

[at 25

°

C (77

°

F)]

3 (+) - 1 (-)

Except 0 or

∞

2 (+) - 1 (-)

3 (+) - 2 (-)

PBIB0194E