Infiniti F50. Manual - part 369

TROUBLE DIAGNOSIS

EC-117

C

D

E

F

G

H

I

J

K

L

M

A

EC

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

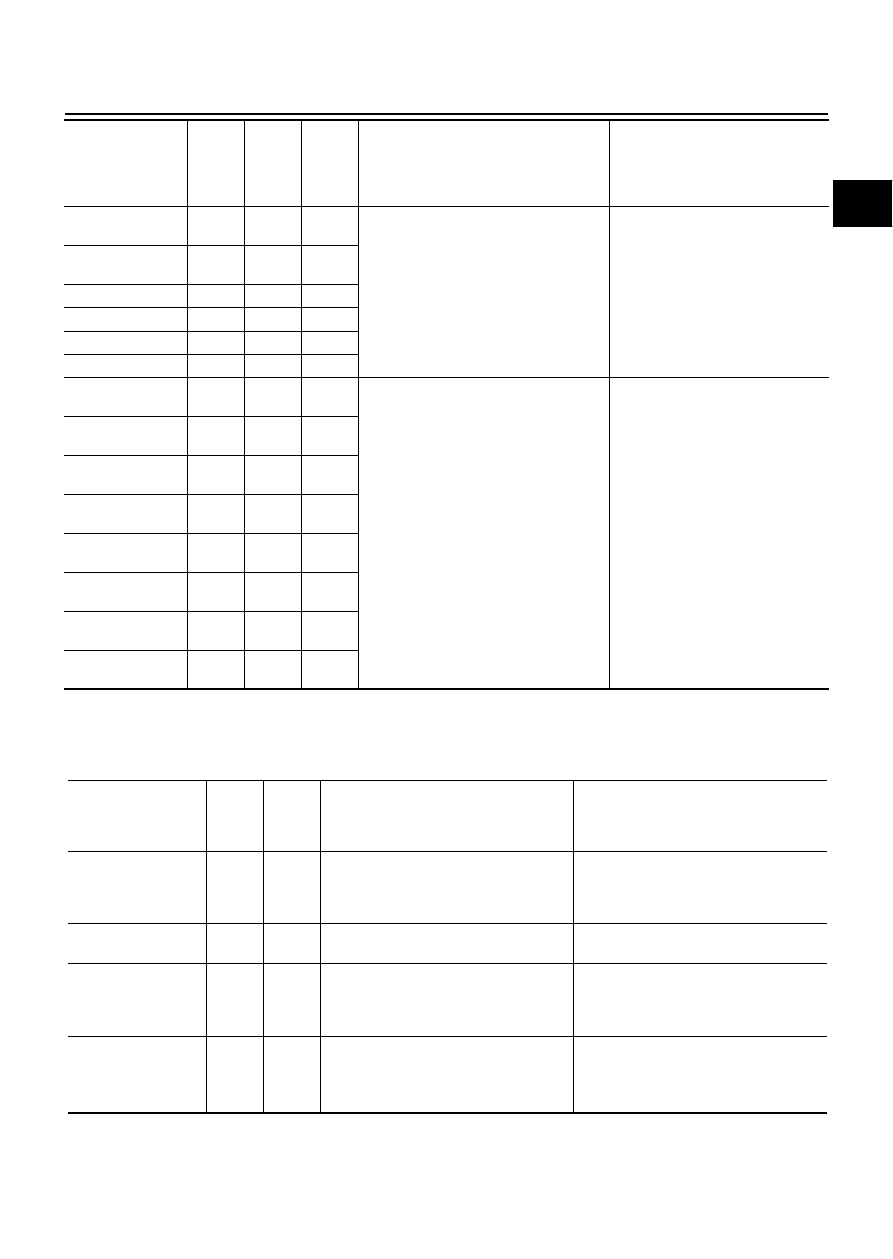

DATA MONITOR (SPEC) MODE

Monitored Item

NOTE:

●

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

Voltage

[V]

●

Voltage, frequency, duty cycle or pulse

width measured by the probe.

●

Only “#” is displayed if item is

unable to be measured.

●

Figures with “#”s are temporary

ones. They are the same figures

as an actual piece of data which

was just previously measured.

Frequency

[msec], [Hz] or [%]

DUTY-HI

DUTY-LOW

PLS WIDTH-HI

PLS WIDTH-LOW

CAN COMM

[OK/NG]

×

●

Indicates the communication condition

of CAN communication line.

●

These items are not displayed in

“SELELTION MENU” mode.

CAN CIRC 1

[OK/UNKWN]

×

CAN CIRC 2

[OK/UNKWN]

×

CAN CIRC 3

[OK/UNKWN]

×

CAN CIRC 4

[OK/UNKWN]

×

CAN CIRC 5

[OK/UNKWN]

×

CAN CIRC 6

[OK/UNKWN]

×

CAN CIRC 7

[OK/UNKWN]

×

Monitored item

[Unit]

ECM

INPUT

SIG-

NALS

MAIN

SIG-

NALS

CAN

DIAG

SUP-

PORT

MNTR

Description

Remarks

Monitored item [Unit]

ECM

INPUT

SIG-

NALS

MAIN

SIG-

NALS

Description

Remarks

ENG SPEED [rpm]

×

×

●

Indicates the engine speed computed

from the signals of the crankshaft posi-

tion sensor (POS) and camshaft position

sensor (PHASE).

MAS A/F SE-B1 [V]

×

×

●

The signal voltage of the mass air flow

sensor specification is displayed.

●

When engine is running specification

range is indicated.

B/FUEL SCHDL

[msec]

●

“Base fuel schedule” indicates the fuel

injection pulse width programmed into

ECM, prior to any learned on board cor-

rection.

●

When engine is running specification

range is indicated.

A/F ALPHA-B1 [%]

A/F ALPHA-B2 [%]

×

●

The mean value of the air-fuel ratio feed-

back correction factor per cycle is indi-

cated.

●

When engine is running specification

range is indicated.

●

This data also includes the data for the

air-fuel ratio learning control.