Infiniti F50. Manual - part 101

ON-VEHICLE SERVICE

AT-289

D

E

F

G

H

I

J

K

L

M

A

B

AT

ON-VEHICLE SERVICE

PFP:00000

Control Valve Assembly

ECS00BFP

CAUTION:

When replacing the control valve assembly, erase EEP ROM in TCM. Refer to

REMOVAL

1.

Disconnect the negative battery terminal

2.

Disconnect heated oxygen sensor 2 harness connector.

3.

Drain ATF through drain plug.

4.

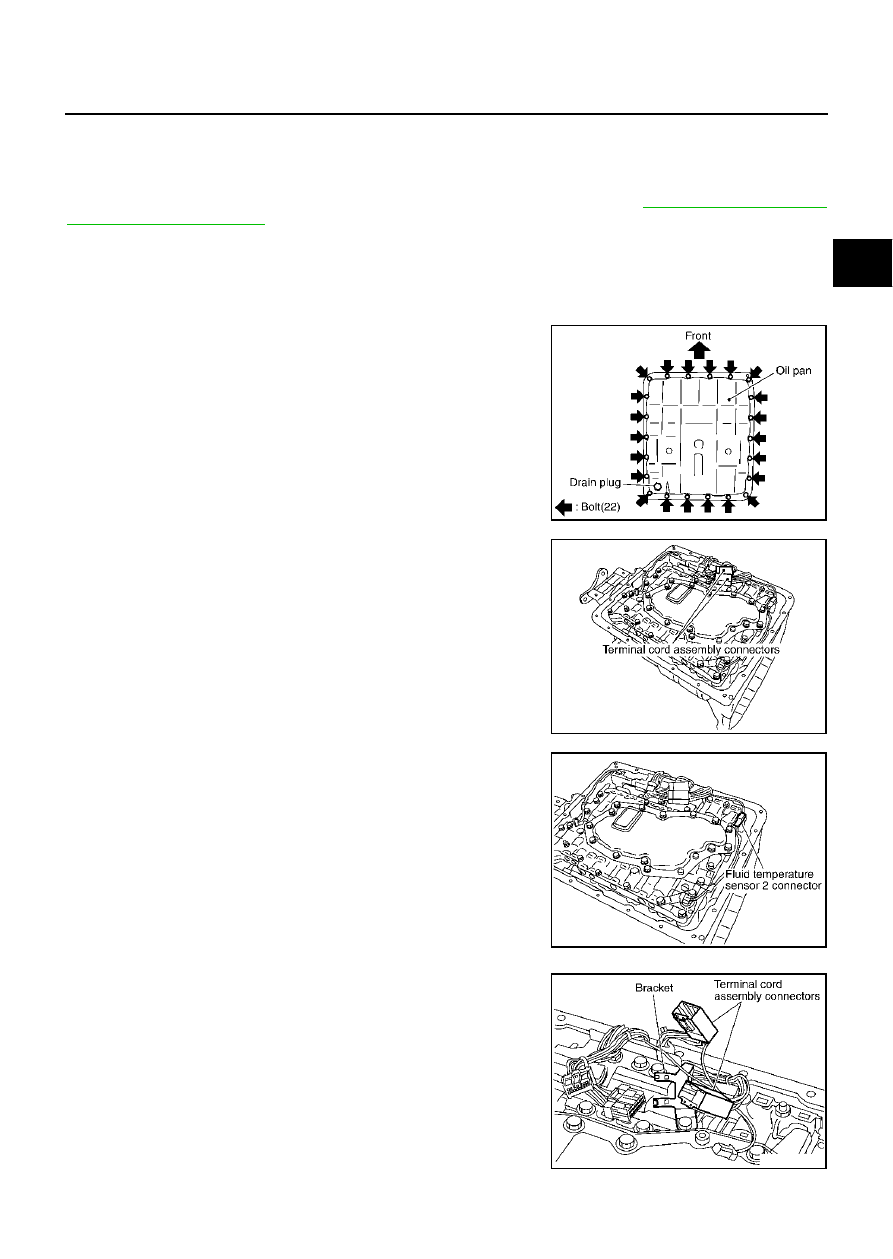

Remove oil pan and oil pan gasket.

5.

Disconnect terminal cord assembly connectors.

CAUTION:

Be careful not to damage connector.

6.

Disconnect fluid temperature sensor 2 connector.

CAUTION:

Be careful not to damage connector.

7.

Remove terminal cord assembly connectors from bracket.

CAUTION:

Be careful not to damage connector.

SCIA2308E

SCIA2309E

SCIA2581E

SCIA2584E