Infiniti G37 Coupe. Manual - part 572

P2138 APP SENSOR

EC-469

< COMPONENT DIAGNOSIS >

[VQ37VHR]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

1.

Check the continuity between APP sensor harness connector and ECM harness connector.

2.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 13.

NO

>> GO TO 12.

12.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors M6, E106

• Harness for open or short between ECM and accelerator pedal position sensor

>> Repair open circuit or short to ground or short to power in harness or connectors.

13.

CHECK APP SENSOR

EC-469, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 15.

NO

>> GO TO 14.

14.

REPLACE ACCELERATOR PEDAL ASSEMBLY

1.

Replace accelerator pedal assembly.

2.

Go to

EC-470, "Special Repair Requirement"

.

>> INSPECTION END

15.

CHECK INTERMITTENT INCIDENT

GI-38, "Intermittent Incident"

.

>> INSPECTION END

Component Inspection

INFOID:0000000001911134

1.

CHECK ACCELERATOR PEDAL POSITION SENSOR

1.

Turn ignition switch OFF.

2.

Reconnect all harness connectors disconnected.

3.

Turn ignition switch ON.

4.

Check the voltage ECM harness connector and ground.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 2.

2.

REPLACE ACCELERATOR PEDAL ASSEMBLY

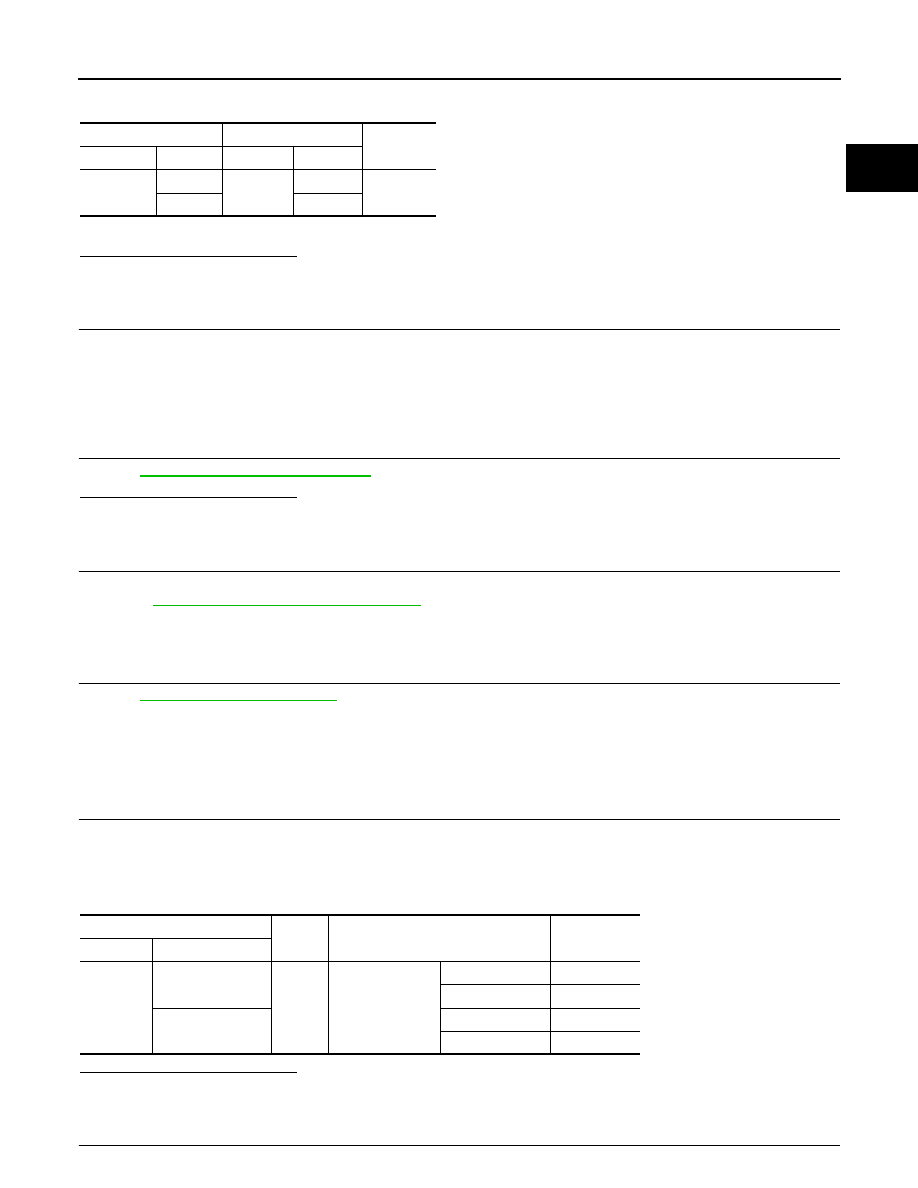

APP sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

E112

3

M107

97

Existed

1

98

ECM

Ground

Condition

Voltage

Connector

Terminal

M107

97 (APP sensor 1)

Ground

Accelerator pedal

Fully released

0.45 - 1.00V

Fully depressed

4.4 - 4.8V

98 (APP sensor 2)

Fully released

0.22 - 0.50V

Fully depressed

2.1 - 2.5V