Infiniti G37 Coupe. Manual - part 444

DLN-90

< REMOVAL AND INSTALLATION >

[REAR FINAL DRIVE: R200V]

REAR FINAL DRIVE ASSEMBLY

1.

Remove center muffler with a power tool. Refer to

2.

Remove rear stabilizer bar with a power tool. Refer to

.

3.

Remove propeller shaft from the final drive. Refer to

.

4.

Remove drive shaft from final drive with a power tool. Then sus-

pend it by wire, etc. Refer to

.

5.

Remove breather hose from the final drive.

6.

Remove rear wheel sensor. Refer to

.

7.

Set a suitable jack to rear final drive assembly.

CAUTION:

Never place a jack on the rear cover (aluminum case).

8.

Remove the mounting bolts and nuts connecting to the suspen-

sion member, and remove rear final drive assembly with a power

tool.

CAUTION:

Secure rear final drive assembly to a suitable jack while

removing it.

INSTALLATION

Note the following, and installation is in the reverse order of removal.

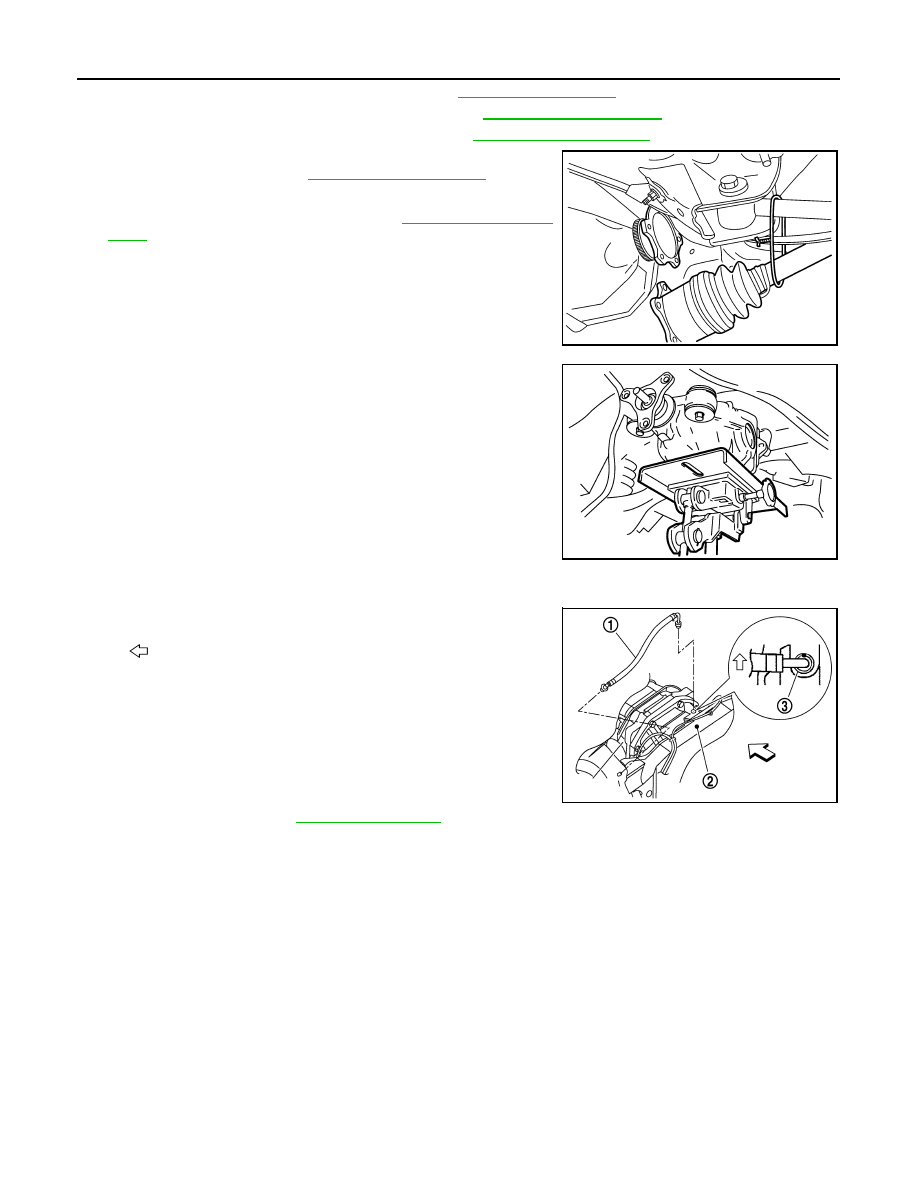

• When installing breather hoses (1), refer to the figure.

CAUTION:

Make sure there are no pinched or restricted areas on the

breather hose caused by bending or winding when installing

it.

- For installation, insert the vehicle side end to suspension member

(2). Install metal connector (3) side of this hose to rear cover by

inserting it with aiming painted marking to the front of vehicle.

• When oil leaks while removing final drive assembly, check oil level

after the installation. Refer to

.

SDIA1094E

JSDIA0026ZZ

: Vehicle front

PDIA0754E