Content .. 1361 1362 1363 1364 ..

Infiniti G37 Coupe. Manual - part 1363

TRANSMISSION ASSEMBLY

TM-305

< DISASSEMBLY AND ASSEMBLY >

[5AT: RE5R05A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

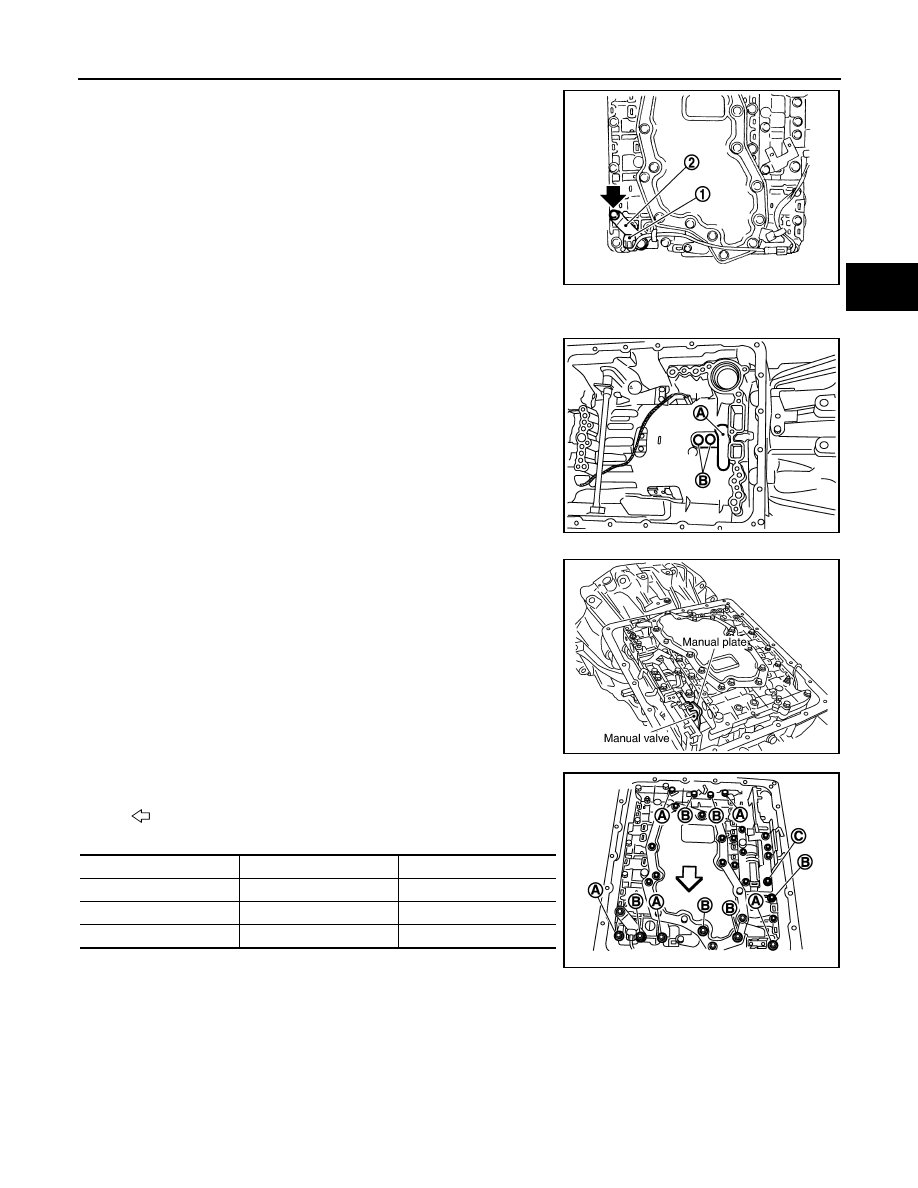

70. Install A/T fluid temperature sensor 2 (1) [with bracket (2)] in

control valve with TCM. Tighten A/T fluid temperature sensor 2

bolt to the specified torque.

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve.

71. Install control valve with TCM in transmission case.

CAUTION:

• Make sure that turbine revolution sensor securely installs

turbine revolution sensor hole (B).

• Hang down revolution sensor harness toward outside so

as not to disturb installation of control valve with TCM.

• Adjust A/T assembly harness connector of control valve

with TCM to terminal hole of transmission case.

• Assemble it so that manual valve cutout is engaged with

manual plate projection.

72. Install bolts A, B and C to control valve with TCM.

JPDIA0013ZZ

A

: Brake band

JPDIA0020ZZ

SCIA5035E

: Front

Bolt symbol

Length

mm (in)

Number of bolts

A

42 (1.65)

5

B

55 (2.17)

6

C

40 (1.57)

1

SCIA8077E