Content .. 1062 1063 1064 1065 ..

Infiniti G37 Coupe. Manual - part 1064

RSU-6

< ON-VEHICLE MAINTENANCE >

WHEEL ALIGNMENT

WHEEL ALIGNMENT

Wheel Alignment Inspection

INFOID:0000000001671749

Description

• Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

General Information and Recommendations

• A four-wheel thrust alignment should be performed.

- This type of alignment is recommended for any NISSAN/INFINITI vehicle.

- The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel is

centered.

- The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

- The rack should be checked to ensure that it is level.

• Make sure the machine is properly calibrated.

- Your alignment equipment should be regularly calibrated in order to give correct information.

- Check with the manufacturer of your specific equipment for their recommended Service/Calibration Sched-

ule.

Alignment Process

IMPORTANT:

Use only the alignment specifications listed in this Service Manual.

• When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do not use these indicators.

- The alignment specifications programmed into your machine that operate these indicators may not be cor-

rect.

- This may result in an ERROR.

• Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). Do not use this “Rolling Compensation” method.

- Use the “Jacking Compensation Method”. After installing the alignment targets or head units, raise the vehi-

cle and rotate the wheels 1/2 turn both ways.

- See Instructions in the alignment machine you're using for more information on this.

Preliminary Check

Check the following:

• Tires for improper air pressure and wear.

• Road wheels for runout. Refer to

• Wheel bearing axial end play. Refer to

.

• Ball joint axial end play of suspension arm. Refer to

• Shock absorber operation.

• Each mounting point of axle and suspension for looseness and deformation.

• Each of front lower link, rear lower link, radius rod, rear suspension member, suspension arm and shock

absorber for cracks, deformation, and other damage.

• Vehicle height (posture).

ADJUSTMENT

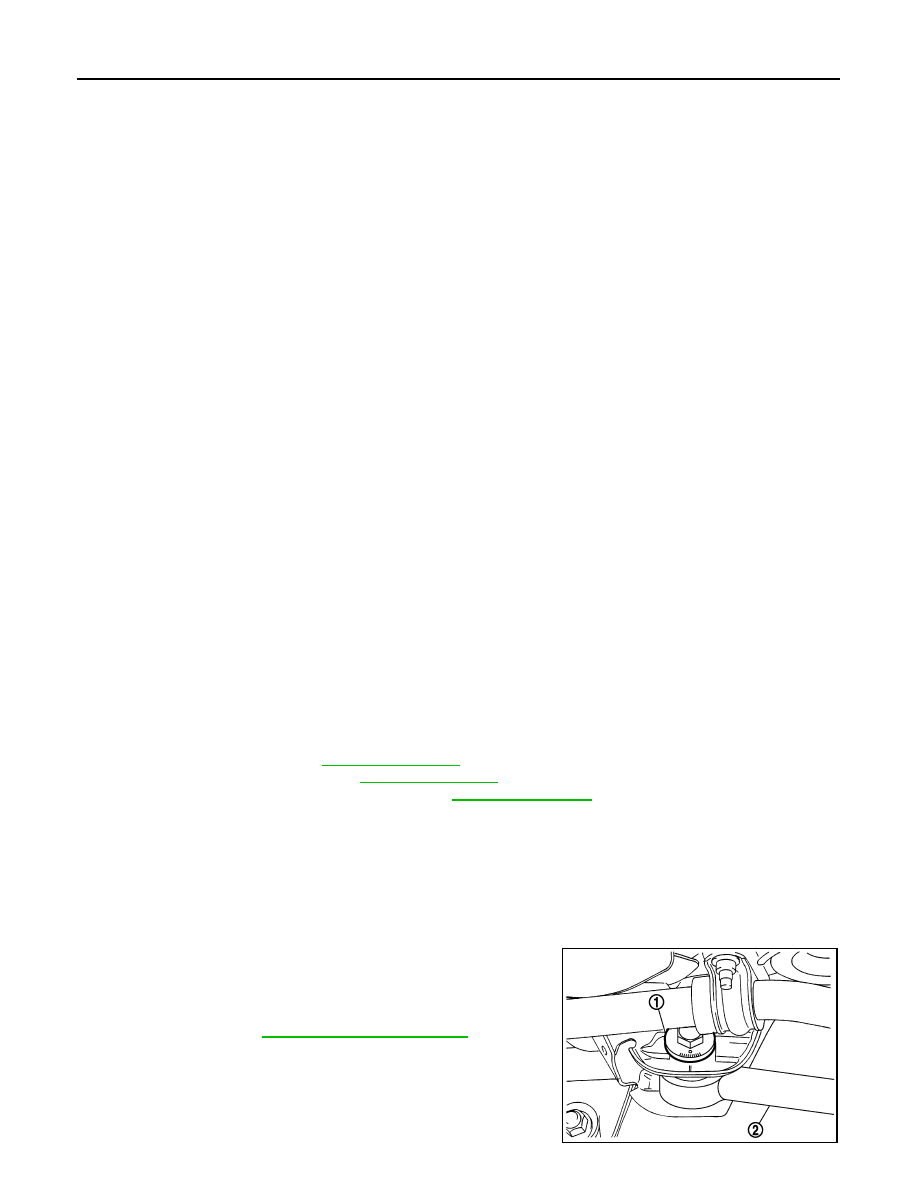

Camber

If outside the standard value, adjust with adjusting bolt (1) in front

lower link (2).

CAUTION:

After adjusting camber, be sure to check toe-in.

Standard

Camber: Refer to

.

JPEIB0061ZZ