Content .. 1017 1018 1019 1020 ..

Infiniti G37 Coupe. Manual - part 1019

POWER WINDOW MOTOR

PWC-17

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

L

M

A

B

PWC

N

O

P

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace harness.

4.

CHECK POWER WINDOW MAIN SWITCH OUTPUT SIGNAL

1.

Connect power wimdow main switch connector.

2.

Turn ignition switch ON.

3.

Check voltage between power window main switch connector and ground.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Replace power window main switch. Refer to

PWC-92, "Removal and Installation"

5.

CHECK INTERMITTENT INCIDENT

GI-38, "Intermittent Incident"

.

>> INSPECTION END

DRIVER SIDE : Component Inspection

INFOID:0000000001693985

COMPONENT INSPECTION

1.

CHECK DRIVER SIDE POWER WINDOW MOTOR

Check motor operation by connecting the battery voltage directly to driver side power window motor connec-

tor.

Is the inspection result normal?

YES

>> Driver side power window motor is OK.

NO

>> Replace driver side power window motor. Refer to

GW-19, "Removal and Installation"

PASSENGER SIDE

PASSENGER SIDE : Description

INFOID:0000000001693987

Door glass moves UP/DOWN by receiving the signal power window main switch or power window sub-switch .

PASSENGER SIDE : Component Function Check

INFOID:0000000001693988

1.

CHECK POWER WINDOW MOTOR CIRCUIT

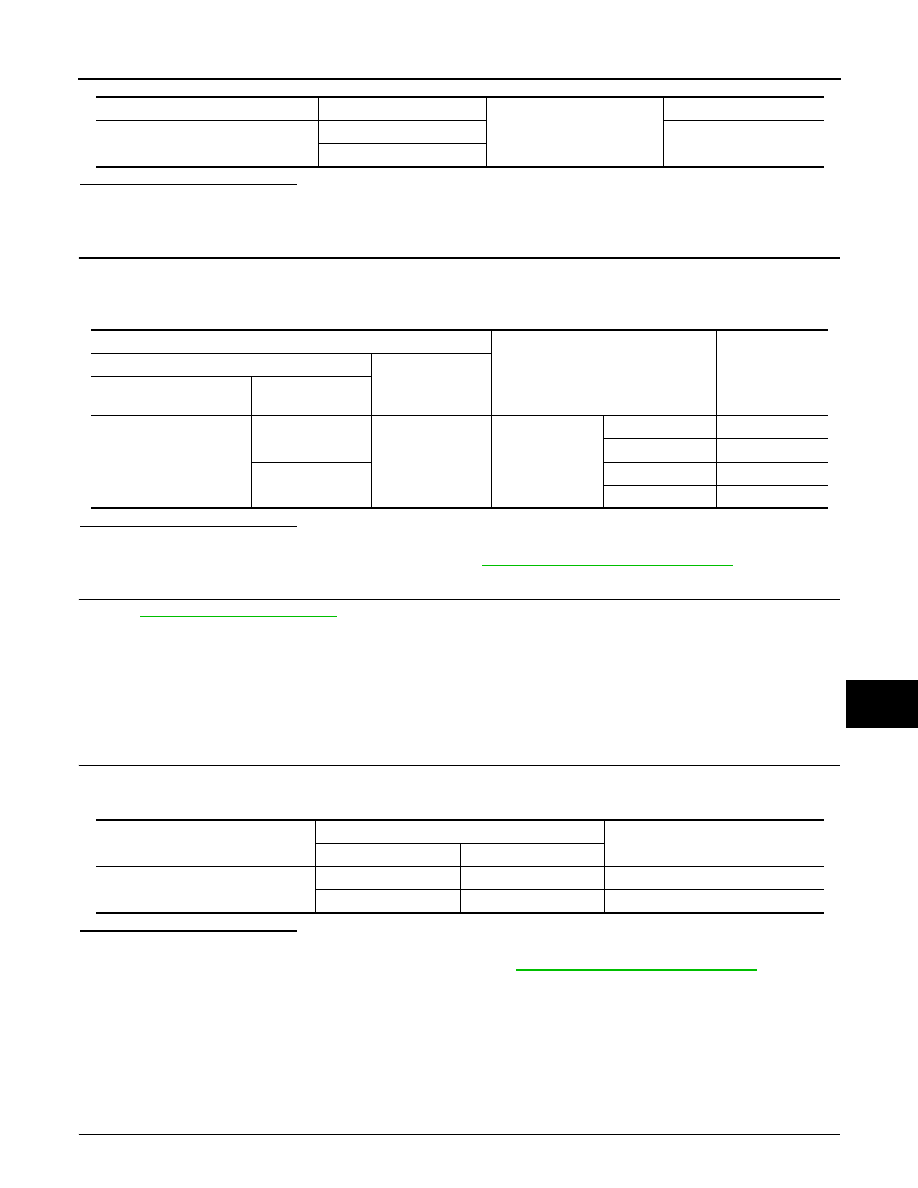

Power window main switch connector

Terminal

Ground

Continuity

D8

8

Not existed

11

Terminal

Power window main switch condition

Voltage (V)

(Approx.)

(+)

(–)

Power window main

switch connector

Terminal

D8

8

Ground

Driver side

UP

Battery voltage

DOWN

0

11

UP

0

DOWN

Battery voltage

Driver side power window motor con-

nector

Terminal

Motor operation

(+)

(–)

D10

3

6

DOWN

6

3

UP