Infiniti G35 (V35) Sedan. Manual - part 741

GW-22

< ON-VEHICLE REPAIR >

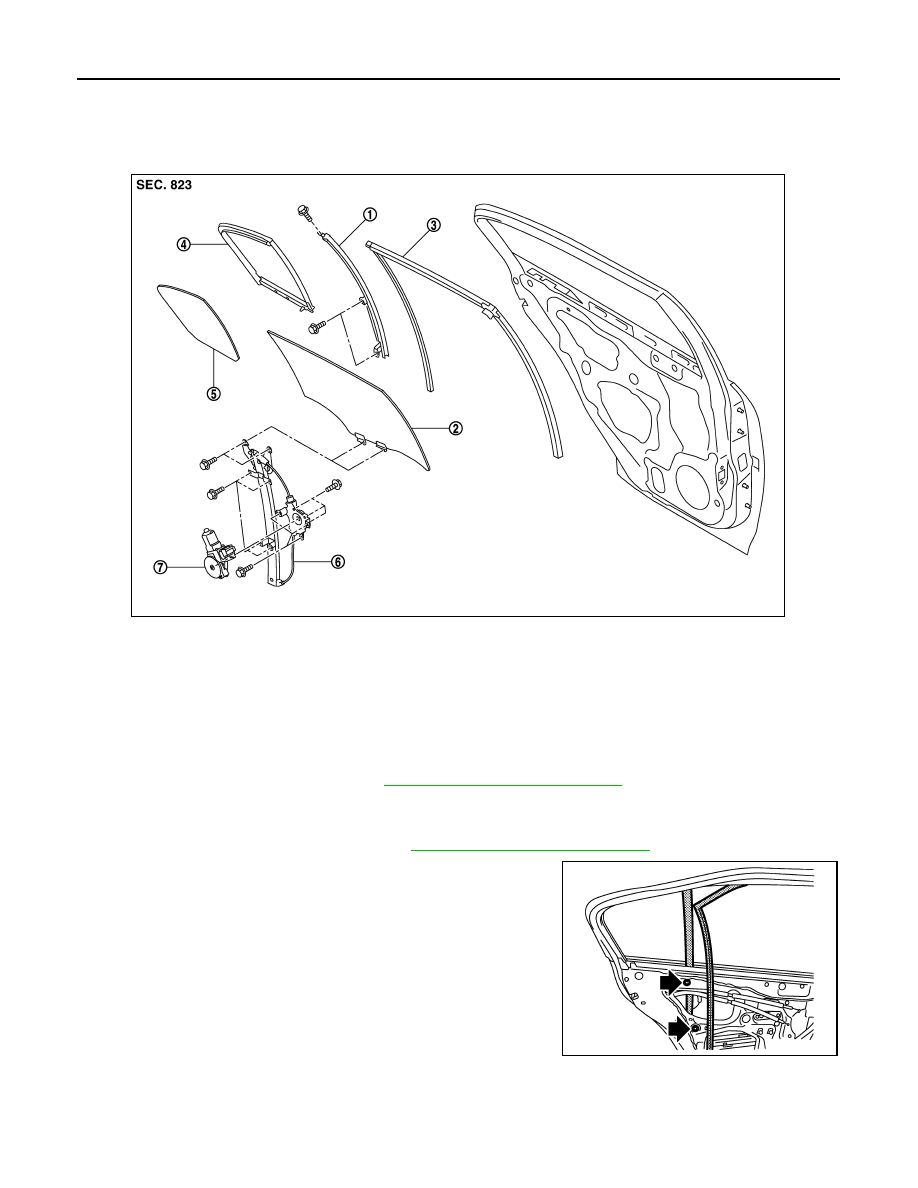

REAR REGULATOR

REAR REGULATOR

Exploded View

INFOID:0000000000961530

Removal and Installation

INFOID:0000000000961531

REMOVAL

1.

Remove the rear door finisher. Refer to

INT-10, "Removal and Installation"

.

2.

Disconnect the rear door speaker connector.

3.

Remove the sealing screen.

4.

Remove the rear door cover inner. Refer to

INT-10, "Removal and Installation"

5.

Remove the door glass run on the partition sash side.

6.

Remove the partition sash fixing screw and bolts and remove

the partition sash.

1.

Partition sash

2.

Door glass

3.

Door glass run

4.

Partition glass run

5.

Partition glass

6.

Regulator assembly

7.

Power window motor

JMKIA0004ZZ

JMKIA0008ZZ