Infiniti G35 (V35) Sedan. Manual - part 714

TRANSVERSE LINK

FSU-13

< ON-VEHICLE REPAIR >

[2WD]

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

TRANSVERSE LINK

Exploded View

INFOID:0000000000957771

Removal and Installation

INFOID:0000000000957772

REMOVAL

1.

Remove tires with power tool.

2.

Remove under cover with power tool.

3.

Remove shock absorber. Refer to

FSU-9, "Removal and Installation"

.

4.

Remove steering outer socket from steering knuckle. Refer to

ST-27, "2WD : Removal and Installation"

.

5.

Remove transverse link from steering knuckle. Refer to

ST-27, "2WD : Removal and Installation"

6.

Set suitable jack under transverse link.

7.

Remove mounting bolts and nuts, and then remove transverse link.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Never tap on the ball joint cap of the stabilizer connecting rod with a hammer or a similar item when

inserting the stabilizer connecting rod into the transverse link.

• Perform final tightening of bolts and nuts at the front suspension member installation and shock absorber

lower side (rubber bushing), under unladen conditions with tires on level ground.

Inspection

INFOID:0000000000957773

INSPECTION AFTER REMOVAL

Visual Inspection

Check the following:

• Transverse link and bushing for deformation, cracks or damage. Replace it if a malfunction is detected.

• Ball joint boot for cracks or other damage, and also for grease leakage. Replace it if a malfunction is

detected.

Ball Joint Inspection

Manually move ball stud to confirm it moves smoothly with no binding.

Swing Torque Inspection

NOTE:

Before measurement, move ball stud at least ten times by hand to check for smooth movement.

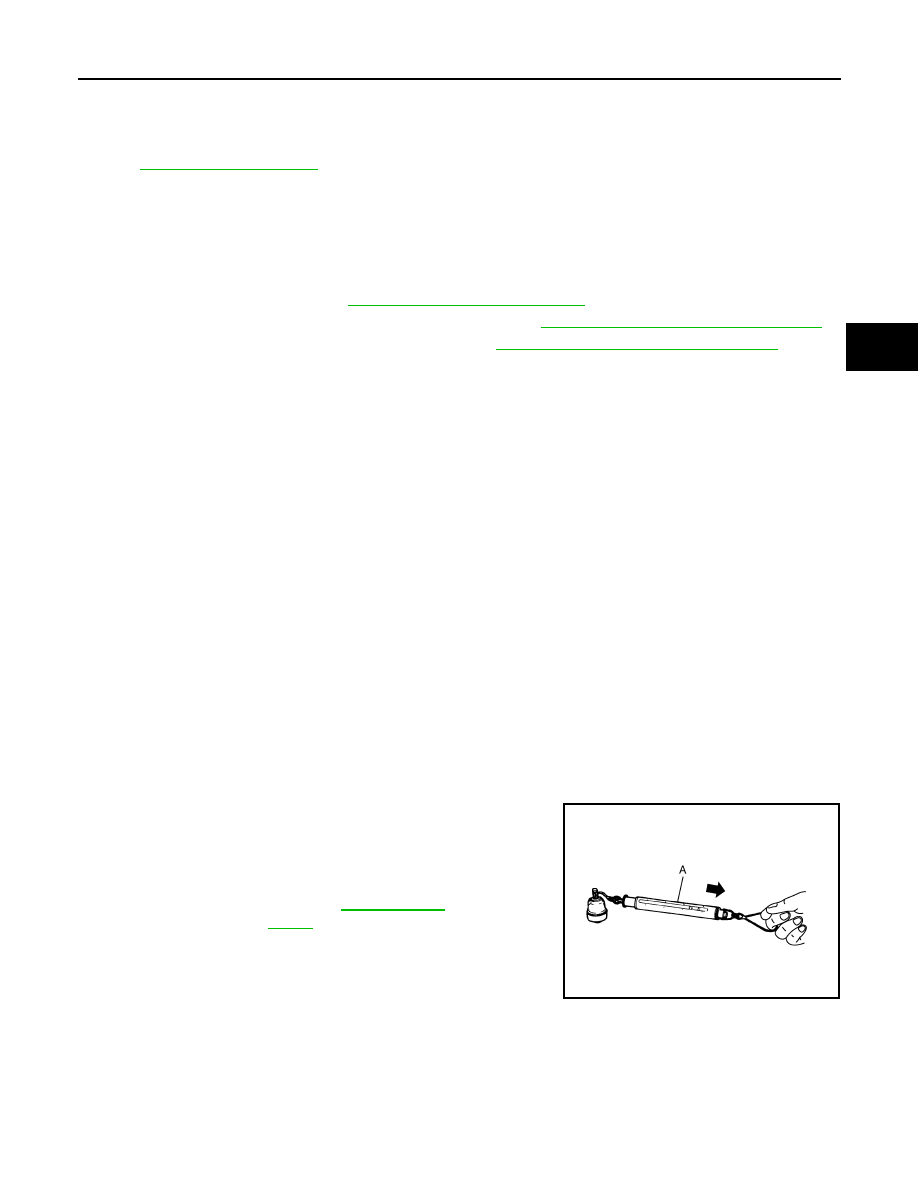

• Hook a spring balance (A) at cotter pin mounting hole. Confirm

spring balance measurement value is within specifications when

ball stud begins moving.

- If it is outside the specified range, replace transverse link assem-

bly.

Rotating Torque Inspection

Standard

Swing toque

: Refer to

JPEIA0005ZZ