Infiniti G35 (V35) Sedan. Manual - part 314

CO-4

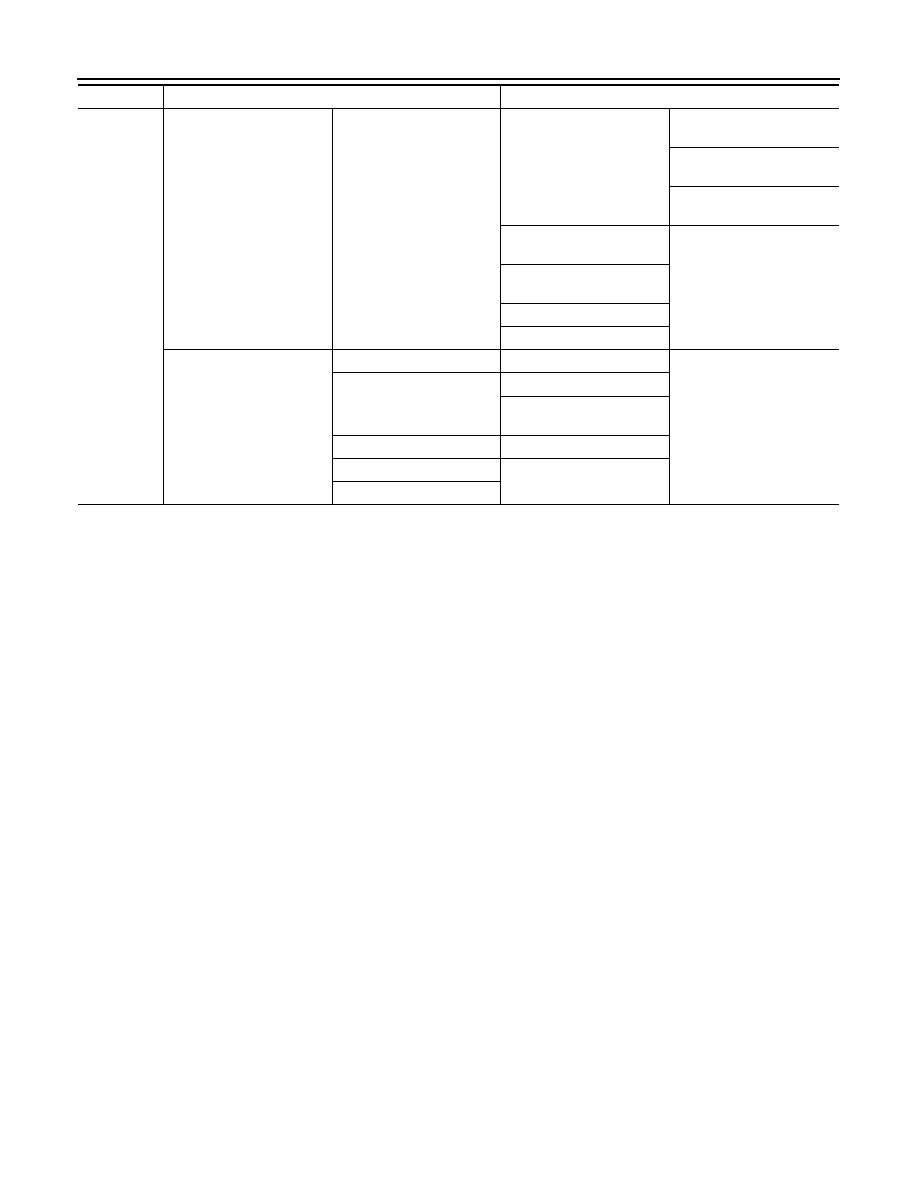

< SYMPTOM DIAGNOSIS >

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function

—

Overload on engine

Abusive driving

High engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

—

Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flow

Blocked bumper

—

—

Blocked radiator grille

Installed car brassiere

Mud contamination or paper

clogging

Blocked radiator

—

Blocked condenser

Blocked air flow

Installed large fog lamp

Symptom

Check items