Infiniti G35 (V35) Sedan. Manual - part 302

CHG

CHARGING SYSTEM

CHG-7

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

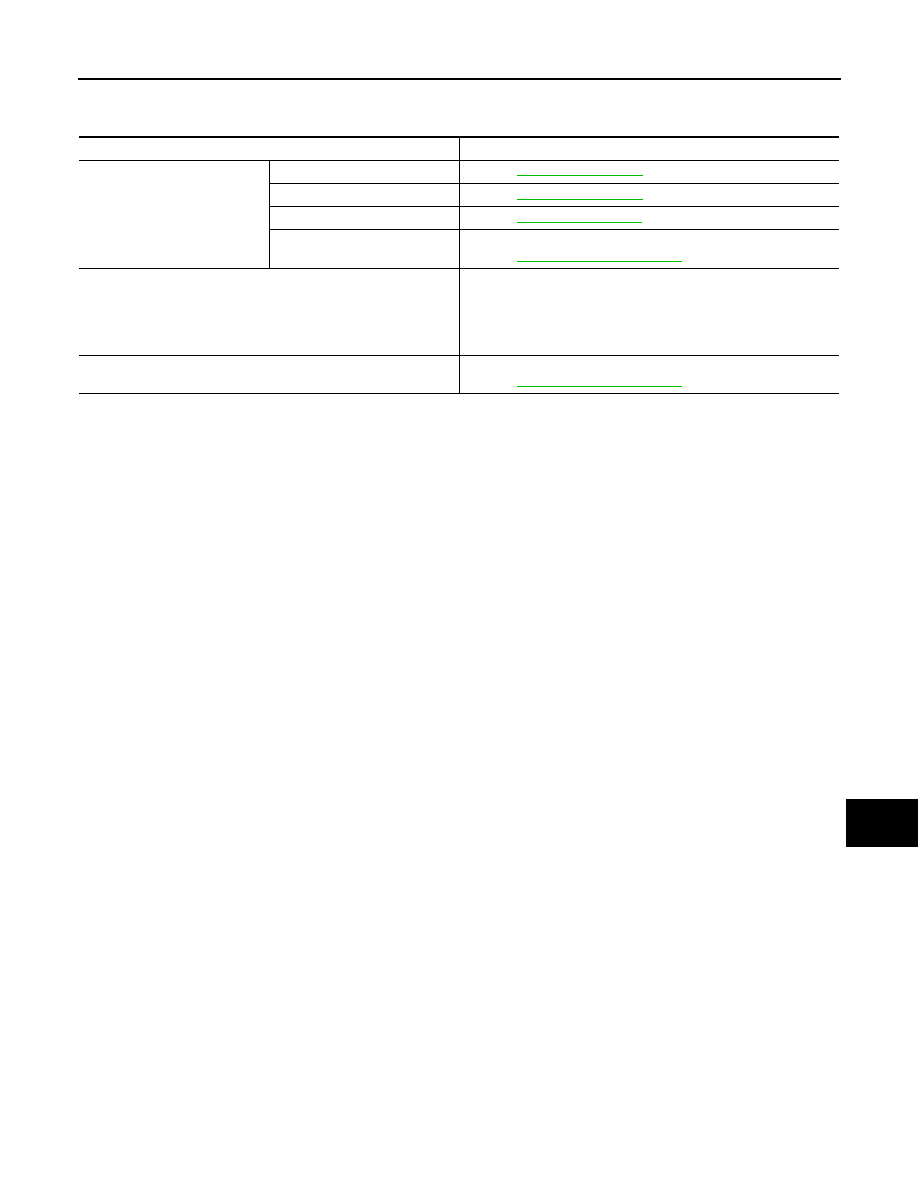

Component Description

INFOID:0000000000964267

Component part

Description

Alternator

“B” terminal

Refer to

.

“S” terminal

Refer to

.

“L” terminal

Refer to

.

“C” terminal

Used for the power generation voltage variable control system.

Refer to

Combination meter (Charge warning lamp)

The IC regulator warning function activates to illuminate the

charge warning lamp, if any of the following symptoms occur while

alternator is operating:

• Excessive voltage is produced.

• No voltage is produced.

IPDM E/R

Used for the power generation voltage variable control system.

Refer to