Content .. 1015 1016 1017 1018 ..

Infiniti G35 (V35) Sedan. Manual - part 1017

PCS-122

< ON-VEHICLE REPAIR >

[POWER DISTRIBUTION SYSTEM]

PUSH BUTTON IGNITION SWITCH

PUSH BUTTON IGNITION SWITCH

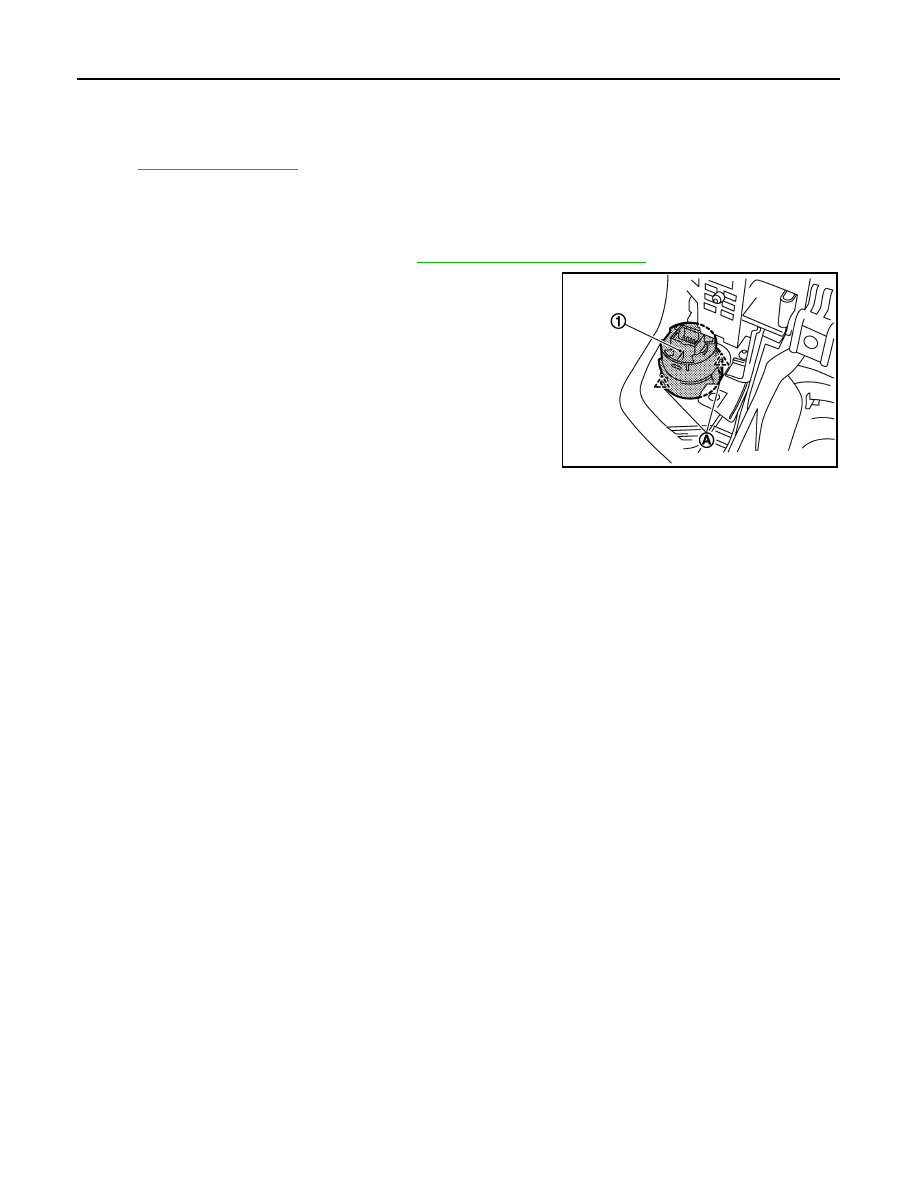

Exploded View

INFOID:0000000000964261

.

Removal and Installation

INFOID:0000000000964262

REMOVAL

1.

Remove the cluster lid A assembly. Refer to

IP-12, "Removal and Installation"

2.

Remove the push-button ignition switch (1) from cluster lid A

assembly, and then remove pawl (A). Press push-button ignition

switch (1) back to disengage from cluster lid A assembly.

INSTALLATION

Install in the reverse order of removal.

JMKIA0167ZZ