Infiniti FX35 / FX45. Manual - part 891

REAR FINAL DRIVE ASSEMBLY

RFD-19

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

M

A

B

RFD

N

O

P

2.

Remove side flanges.

3.

Rotate drive pinion back and forth 2 to 3 times to check for unusual noise and rotation malfunction.

4.

Rotate drive pinion at least 20 times to check for smooth operation of the bearing.

5.

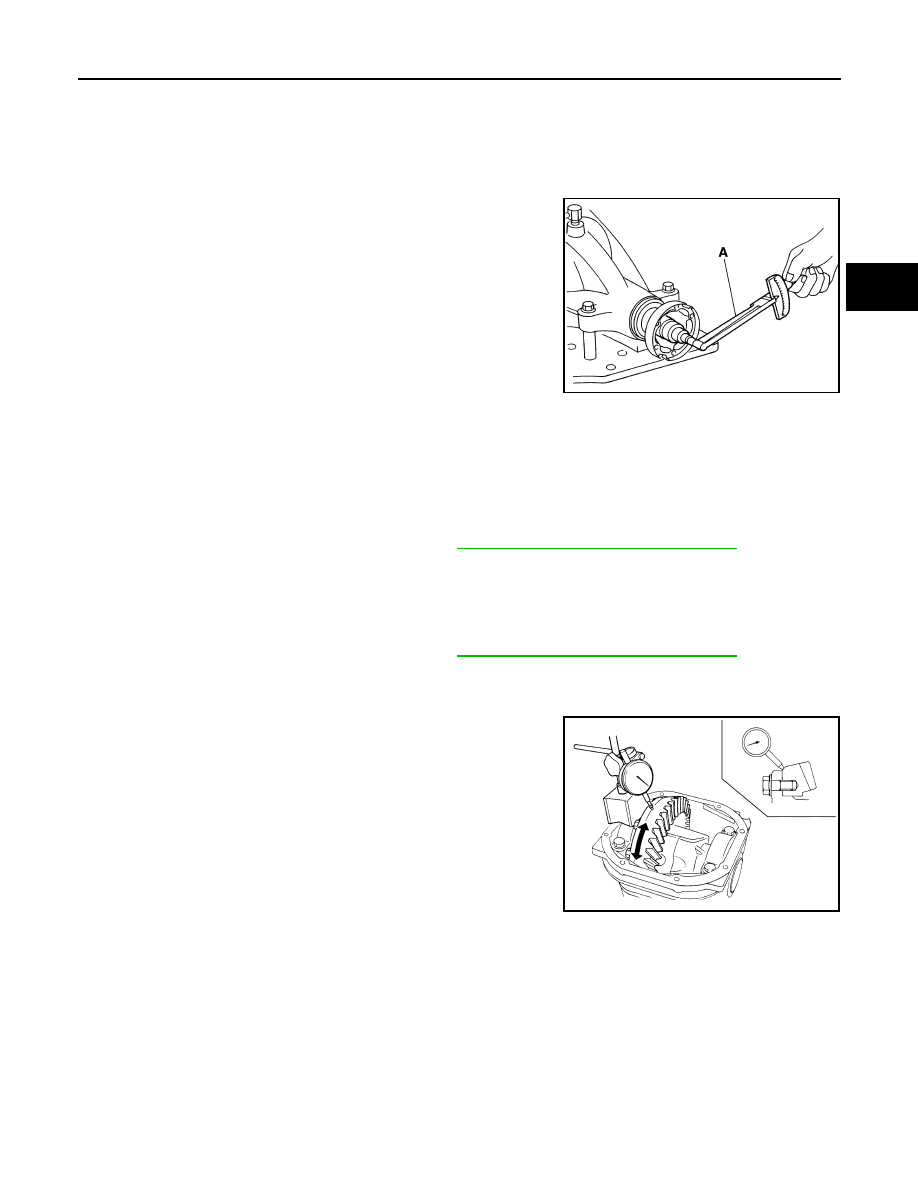

Measure total preload with the preload gauge.

NOTE:

Total preload torque = Pinion bearing preload torque + Side

bearing preload torque

• If measured value is out of the specification, disassemble it to

check and adjust each part. Adjust the pinion bearing preload and

side bearing preload.

Adjust the pinion bearing preload first, then adjust the side bearing preload.

Drive Gear Runout

1.

Remove rear cover. Refer to "Differential Assembly".

2.

Fit a dial indicator to the drive gear back face.

3.

Rotate the drive gear to measure runout.

• If the runout is outside of the repair limit, check drive gear assem-

bly condition; foreign material may be caught between drive gear

and differential case, or differential case or drive gear may be

deformed, etc.

CAUTION:

Replace drive gear and drive pinion gear as a set.

Tooth Contact

1.

Remove rear cover. Refer to "Differential Assembly".

Tool number

A: KV38100800 (J-25604-01)

Tool number

A: ST3127S000 (J-25765-A)

Total preload torque:

2.85 - 3.75 N·m (0.29 - 0.38 kg-m, 26 - 33 in-lb)

PDIA0766J

When the preload torque is large

On pinion bearings:

Replace the collapsible spacer.

On side bearings:

Use thinner side bearing adjusting washers by the same amount to

each side. Refer to

RFD-38, "Inspection and Adjustment"

.

When the preload is small

On pinion bearings:

Tighten the drive pinion lock nut.

On side bearings:

Use thicker side bearing adjusting washers by the same amount to

each side. Refer to

RFD-38, "Inspection and Adjustment"

.

Runout limit:

0.05 mm (0.0020 in)

SPD886