Infiniti FX35 / FX45. Manual - part 890

SIDE OIL SEAL

RFD-15

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

M

A

B

RFD

N

O

P

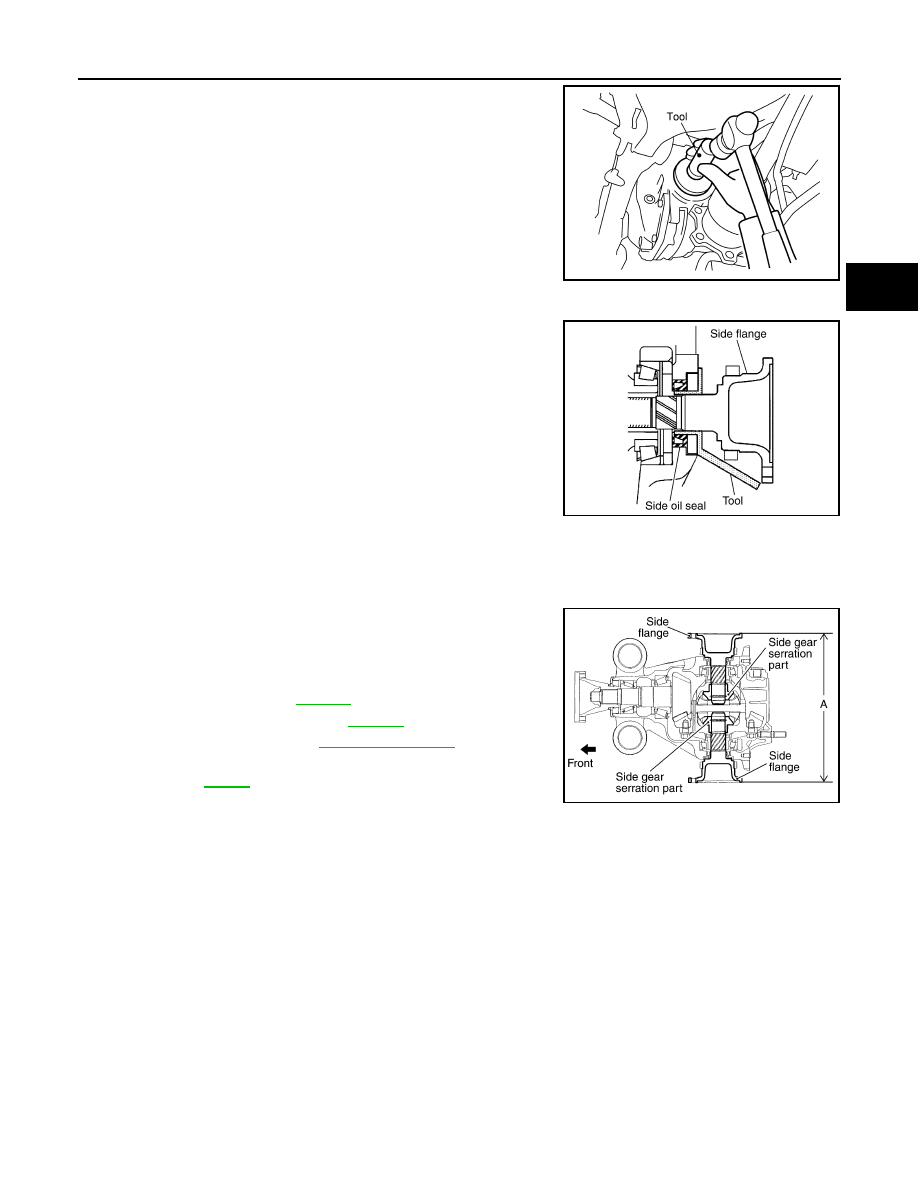

2.

Install side oil seal until it becomes flush with the case end,

using the drift.

CAUTION:

• Never reuse oil seal.

• When installing, never incline oil seal.

3.

Install side flange with the following procedure.

a.

Attach the protector to side oil seal.

b.

After the side flange is inserted and the serrated part of side

gear has engaged the serrated part of flange, remove the pro-

tector.

c.

Put a suitable drift on the center of side flange, then drive it until sound changes.

NOTE:

When installation is completed, driving sound of the side flange turns into a sound which seems to affect

the whole final drive.

d.

Confirm that the dimension of the side flange installation (Mea-

surement A) in the figure comes into the following.

4.

Install drive shaft. Refer to

.

5.

Install rear wheel sensor. Refer to

6.

Install center muffler. Refer to

7.

When oil leaks while removing, check oil level after the installa-

tion. Refer to

.

Tool number

: KV38100200 (J-26233)

SDIA1585E

Tool number

: KV38107900 (J-39352)

SDIA0822E

Measurement A: 326 - 328 mm (12.83 - 12.91 in)

SDIA1039E